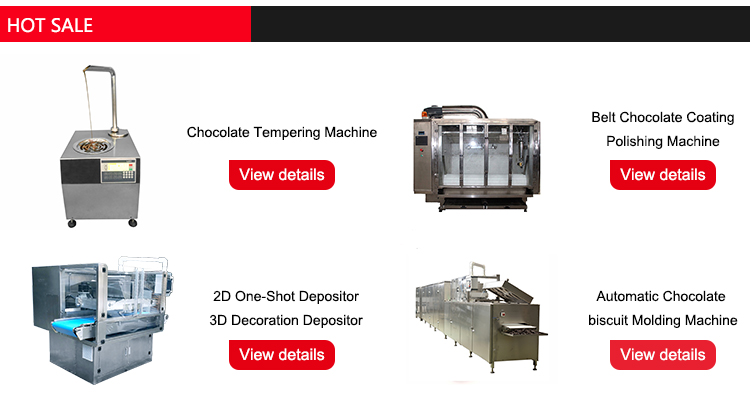

Maarumondi akaomeswa chokoreti polishing muchina nzungu nzungu chokoreti yekuisa muchina ari kutengeswa

- Zita reBrand:

- LST

- Nzvimbo Yekwakabva:

- Sichuan, China

- Voltage:

- 380V

- Simba(W):

- 24Kw

- Dimension(L*W*H):

- 2550*1600 *2650

- Kurema

- 800kg

- Certification:

- CE

- Warranty:

- 1 gore

- Mushure mekutengesa Sevhisi Yakapihwa:

- Kuisirwa munda, kutumwa uye kudzidziswa, Mainjiniya anowanikwa kumichina yekushandira mhiri kwemakungwa

- Nzvimbo dzekushandisa:

- Snack chikafu fekitori, Beverage Factory

- Michina Basa:

- Coating, polishing

- Raw material:

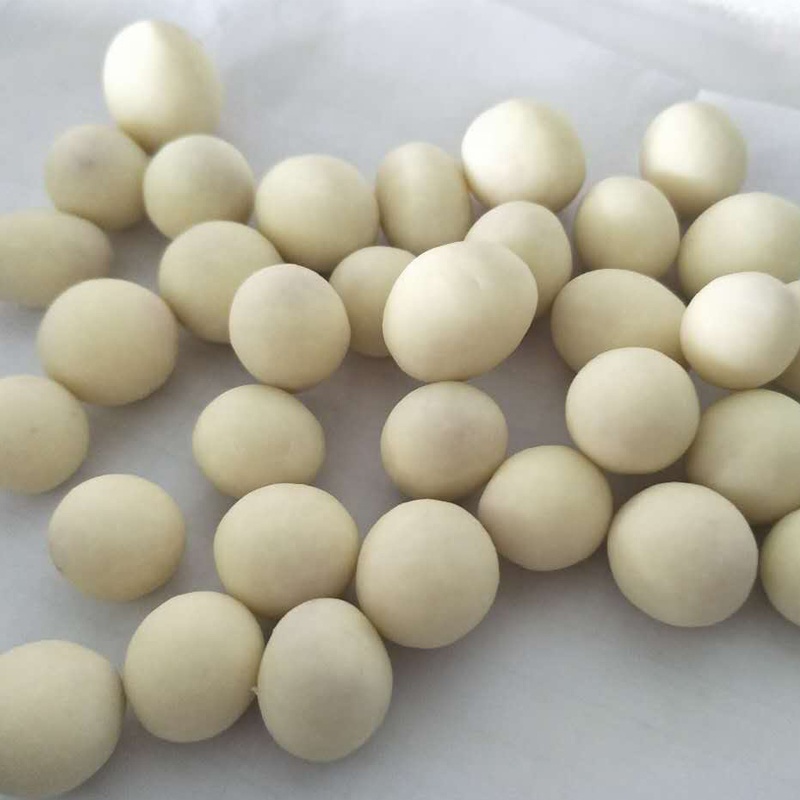

- Michero, Nzungu, Soyabhinzi, Miriwo, Nzungu.etc

- Zita rechigadzirwa:

- Chokoreti chikafu

- Condition:

- New

- Application:

- Chocolate

Maarumondi akaomeswa chokoreti polishing muchina nzungu nzungu chokoreti yekuisa muchina ari kutengeswa

Chocolate Coating & Molding muchina uye Chocolate Polishing muchina anonyanya kushandiswa muzvigadzirwa zvakakanyiwa nenzungu, maarumondi, mazambiringa akaomeswa, mabhora emupunga akapushwa, Jelly candies, candies hard, QQ candies etc.

| Output | 200-400kg/h 330L/batch |

| Total Power | 12KW |

| Dimension | 2450-1650-2250mm |

| Net Weight | 800kg |

| Bhandi Speed | 5-20m/min |

| Belt Width | 1650mm |

| Air Compressed | 0.4MPa |

| Magetsi | 380V 50HZ kana yakagadzirirwa |

Nzira yekugadzira:

Nokuda kwechigadzirwa chakakosha

1.Kune zvigadzirwa zvisina kusimba uye chigadzirwa chakazvitutumadza, Diameter ≥4mm, stuffed material ≤250 litres.Iyo yakanyanya kusimba, iyo ishoma zvinhu.

2.Kune zvigadzirwa zvine kona uye kumucheto, kutenderera chimiro uye kuenderana ukobvu hazvikurudzirwe.

3.Kune chigadzirwa chekunamatira, isa zvinhu zvishoma zvekunamatira.Kana zvinhu zvinonamatira pamwechete uye kuita kuumbwa.

4.Pachokoreti paste, zvinodikanwa kusefa usati wawedzera kuti udzivise block of spray nozzle.

Chocolate coating machine

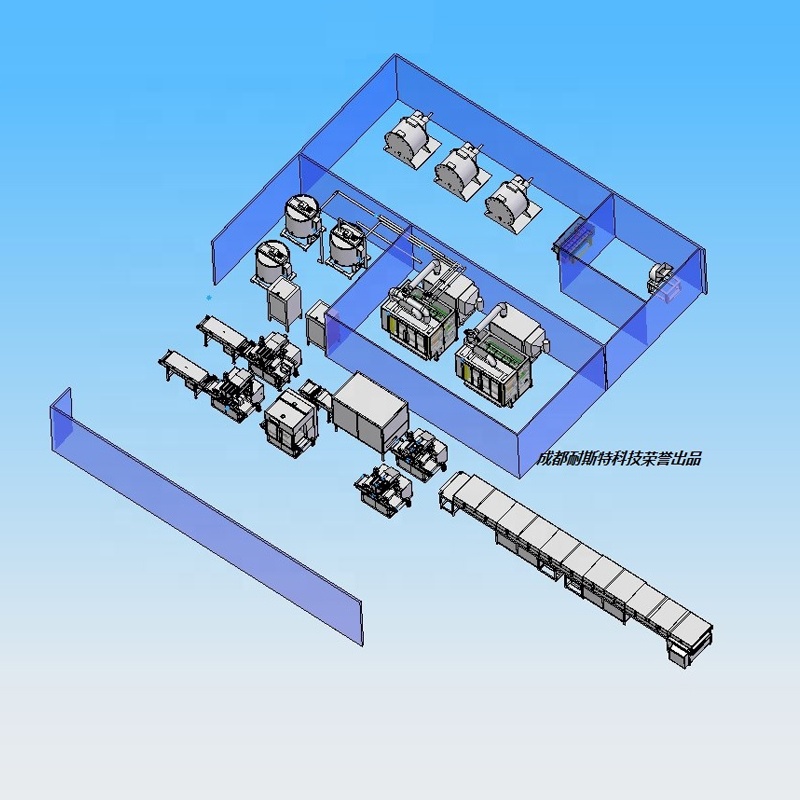

Main ine 3 michina seinotevera:

(1) chocolate coating machine

(2) . chocolate material feeding system

(3) 8P maindasitiri efiriji zvikamu(kutonhodza kwemvura uye kutonhora kwemhepo yekumanikidza)

Murayiridzo mukuru

1).Chocolate Coating Machine

1 Adopts PLC control, inogona kuchengetedza marudzi ese echigadzirwa formula.Program control production process.

2 Zvinoenderana nezvakasiyana zvechigadzirwa, inogona kusetwa kupfapfaidza simba uye nguva yekupfapfaidza nechirongwa.

3 Inodyiwa giredhi PU bhandi .Namira ichatenderera mukumhanya kwakanyanya nebasa rebhandi.

4 Magetsi anoyera otomatiki kuyera

5 Full otomatiki chirongwa kutonga

6 otomatiki yekudyisa sisitimu huru ine chokoreti yekuchengetera tangi (chokoreti insulation silinda), chokoreti slurry pombi, simbi isina simbi inopinza insulating pombi.

2).Chocolate Feeding System(chokoreti pombi uye 500L chokoreti yekuchengetedza tank)

Main ine 2 michina seinotevera:

(1)S304 simbi isina tsvina chokoreti yekuchengetedza tank (500L/1000L)

(2)Stainless simbi interlayer insulating pombi uye pombi

Iyo yekudyisa sisitimu yekuchengetera uye yekudyisa chokoreti zvinhu kune chokoreti yekubikisa muchina.

3).Chocolate Cooling Machine

Refrigeration System :8P refrigeration units Cocoa butter chokoreti kana yakasanganiswa cocoa butter chokoreti tembiricha yekunamira: 14-16 ℃;tembiricha yemhepo inoputika:10-12℃;hunyoro hwehukama:<50%.Chirongwa chekudzora muchina mukuru nezvikamu zvefiriji realise production process cooling start .mira uye tembiricha.

Production Site Environment Condition

1.Single room ye chocolate coating machine uye chocolate coating machine .Inofanira kuisa air-condition uye Dehumidity dryer kuti iite tembiricha yekamuri ≤20℃ uye humidity ≤50%.

2.Both machine inogona kuiswa pane imwe kamuri, nzvimbo yekamuri inenge 15square.

3.Chocolate mushure me enrob,inoda mhepo yakaoma kuona pane tembiricha10℃-15℃ uye humidity ≤50%.

4.4Mpa yakadzvanywa mweya wekupa, inofanirwa kunge iine mweya wekupa yekubatanidza scochet.