Chocolate Polishing Machine Automatic Chocolate Bean Enrobing Coating Machine

- Applicable Industries:

- Chikafu & Chinwiwa Factory

- Zita reBrand:

- LST

- Nzvimbo Yekwakabva:

- Sichuan, China

- Voltage:

- 330/380V

- Simba(W):

- 24kw

- Dimension(L*W*H):

- 1800*1600*1500mm

- Kurema

- 300kg

- Certification:

- CE ISO

- Warranty:

- 1 gore

- Nzvimbo dzekushandisa:

- Snack chikafu fekitori, Beverage Factory

- Michina Basa:

- kukoira/kupolisha

- Raw material:

- Muchero, Nzungu

- Zita rechigadzirwa:

- chokoreti

- Condition:

- New

- Application:

- CANDY

- Mushure mekutengesa Sevhisi Yakapihwa:

- Mainjiniya anowanikwa kumichina yekushandira mhiri kwemakungwa, Kuisa Munda, kutumira uye kudzidziswa

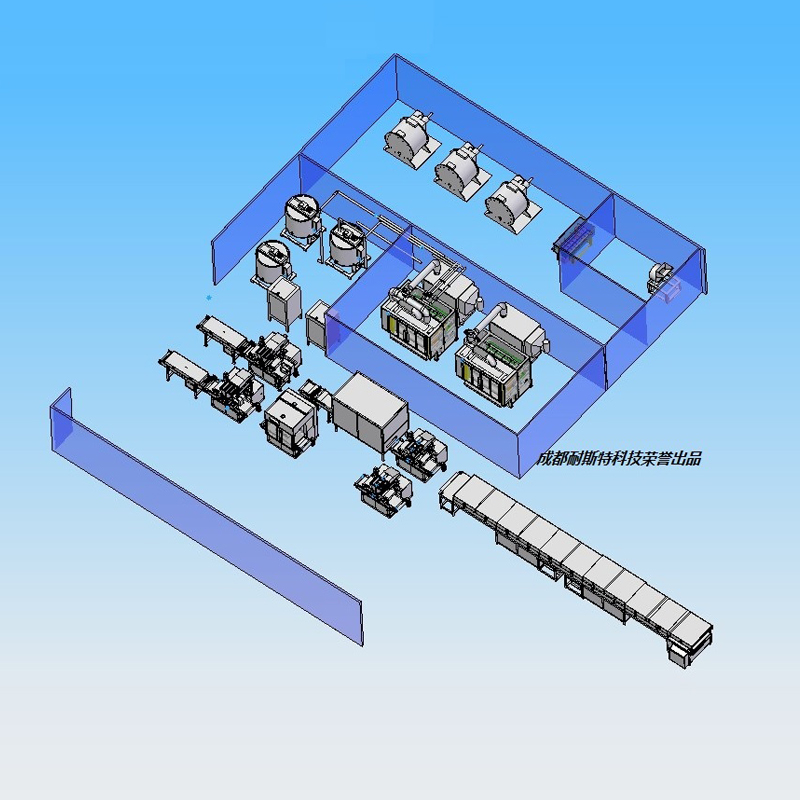

Chocolate polishing muchina otomatiki chokoreti bhinzi enrobing coating muchina

1. Chocolate coating machine

Main ine 3 michina seinotevera:

(1) chocolate coating machine

(2) . chocolate material feeding system

(3) 8P maindasitiri efiriji zvikamu(kutonhodza kwemvura uye kutonhora kwemhepo yekumanikidza)

(1) .Main rairo yemuchina wekuputira chokoreti

Chocolate Coating Machine

1Adopts PLC control, inogona kuchengetedza marudzi ese echigadzirwa formula.Program control production process.

2 Zvinoenderana nezvakasiyana zvechigadzirwa, inogona kusetwa kupfapfaidza simba uye nguva yekupfapfaidza nechirongwa.

3 Edible giredhi PU bhandi .Namira ichatenderera mukumhanya kwakanyanya nebasa rebhandi.

4 Magetsi anoyera otomatiki kuyera

5 Yakazara otomatiki chirongwa chekudzora

6 otomatiki yekudyisa sisitimu huru ine chokoreti yekuchengetera tangi (chokoreti insulation silinda), chokoreti slurry pombi, simbi isina simbi inopinza insulating pombi.

Chocolate Storage Tangi

2.Chocolate Feeding System(chokoreti pombi uye 500L chokoreti yekuchengetedza tank)

Main ine 2 michina seinotevera:

(1)S304 simbi isina tsvina chokoreti yekuchengetedza tank (500L/1000L)

(2)Stainless simbi interlayer insulating pombi uye pombi

Main control mode

Iyo yekudyisa sisitimu yekuchengetera uye yekudyisa chokoreti zvinhu kune chokoreti yekubikisa muchina.

Chocolate Cooling Machine

Refrigeration System :8P refrigeration units Cocoa butter chokoreti kana yakasanganiswa cocoa butter chokoreti tembiricha yekunamira: 14-16 ℃;tembiricha yemhepo inoputika:10-12℃;hunyoro hwehukama:<50%.Chirongwa chekudzora muchina mukuru nezvikamu zvefiriji realise production process cooling start .mira uye tembiricha.

2.Dry Storage (nemutengi)

Mutengi anopa imwe kamuri ,inove yakakura kudarika 15 square low tembiricha uye humidity .Chocolate ichaisa mukamuri inenge 8-10hours kuti ibvise humidify uye kusimba.Saka chokoreti ichawedzera kupenya uye kuchengeta nguva refu.

Kurudzira mutengi kuti agadzire akawanda-layer furemu yezita rechokoreti.

Production Site Environment Condition

1.Single room ye chocolate coating machine uye chocolate coating machine .Inofanira kuisa air-condition uye Dehumidity dryer kuti iite tembiricha yekamuri ≤20℃ uye humidity ≤50%.

2.Both machine inogona kuiswa pane imwe kamuri, nzvimbo yekamuri inenge 15square.

3.Chocolate mushure me enrob,inoda mhepo yakaoma kuona pane tembiricha10℃-15℃ uye humidity ≤50%.

4.4Mpa yakadzvanywa mweya wekupa, inofanirwa kunge iine mweya wekupa yekubatanidza scochet.

Kana kusaina chibvumirano, mutengi anofanira kutsanangura magetsi uye frequency kutanga.

Kugadzira Mamiriro uye Zvinodiwa

5.Kutonhora kwezvikamu zvetembiricha renji 5-10 ℃,tembiricha yemukamuri 14-20℃,humidity≤50%.

6.Kutonhora kwekuchengetera tembiricha 10-15 ℃, inotonhora yekuchengetedza nguva 8-10 maawa, kuvimbisa chokoreti kumusoro kwakatsetseka uye kuoma.

7.Debugger ichagadzirisa mishonga uye zvikamu zvose zvichagamuchira muchina maererano nepamusoro pezvinodiwa.Kana chokoreti yemutengi uye mamiriro ekugadzira asina kukodzera, saka ita kuti chokoti irege kugadzikana uye kusabvumirwa, mutengesi haazotora chero mutoro.

8. Debugger chete debugger uye dzidzisa nezve 2-3 pics chokoreti, imwe neimwe yakawedzerwa chokoreti, muripo wekugadzirisa :¥2000.

9. Gore rimwe waranti nguva mukushanda kwakajairwa, mutengo wemuchina webasa nekuda kwekushanda kwakashata.

Debugging Kushanda

1.Standard debugging nguva 5-10 mazuva apo debugger debug chokoreti yekupedzisira pafekitari yemutengi.

2.Mumwe mainjiniya ane hunyanzvi anobatsira debugger kugadzirisa uye kudzidza muchina.

(1) Kakamuri kadiki kadiki kakapatsanurwa kechokoreti yekupeta nemichina yekupukuta.air-conditioner uye dehumidifier zvinodiwa kuchengetedza tembiricha yekamuri ≤20 ℃ uye humidity ≤50%.

(2) Michina miviri iyi inogona kuiswa mune imwe kamuri iyo inenge 15 square metres.

(3) Mushure mekuumbwa, chokoreti inoda kuve yakasikwa yakaomeswa mu10 ℃-15 ℃ uye humidity ≤50% nharaunda.

(4) 4Mpa yakamanikidzwa mweya wekupa (nemutengi)

(5) Kutonhora kwezvikamu 'tembiricha ye5-10 ℃, tembiricha yekamuri 14-20 ℃, humidity≤50%.

(6) Firiji tembiricha siyana 10-15.8-10 maawa 'firiji yekuvimbisa yakatsetseka uye yakaoma nzvimbo.

Chocolate Polishing muchina unonyanya kushandiswa muzvigadzirwa zvakakanyiwa nenzungu, maarumondi, mazambiringa akaomeswa, mabhora emupunga akazvitutumadza, jelly candies, hard candies, QQ candies etc.

Nokuda kwechigadzirwa chakakosha

1. Zvezvigadzirwa zvisina kusimba uye chigadzirwa chakazvitutumadza, dhayamita ≥4mm, zvinhu zvakakanyiwa ≤250 malita.Iyo yakanyanya kusimba, iyo ishoma zvinhu.

2. Kune zvigadzirwa zvine kona nemapendero, chimiro chakatenderedzwa uye kuenderana ukobvu hazvikurudzirwe.

3. Nokuda kwechigadzirwa chekunamatira, isa zvinhu zvishoma zvekunamatira.Kana zvinhu zvinonamatira pamwechete uye kuita kuumbwa.

4. Pachokoreti paste, zvinodikanwa kusefa usati wawedzera kuti udzivise block of spray nozzle.

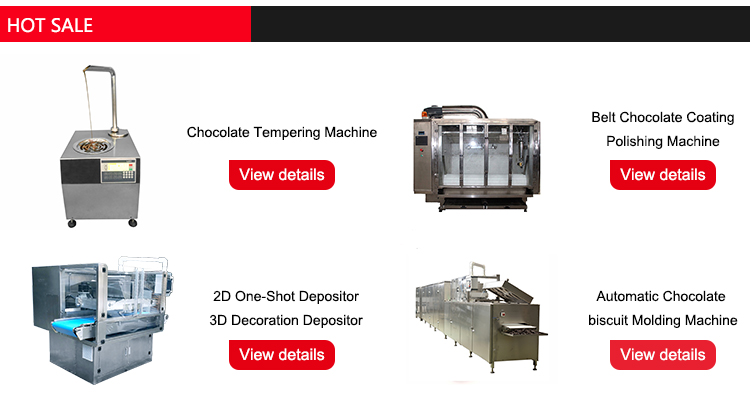

Yakavambwa muna 2009, Chengdu LST ine timu yeR&D yehunyanzvi uye midziyo yakasarudzika, inoshanda mukugadzira yepakati-yepamusoro kirasi yemidziyo yechokoreti, senge Chokoreti yekuumba Michina, michina yekupotera chokoreti, muchina wechokoreti enrobing, chokoreti & musanganiswa wezviyo wekuumba muchina, bhora rechigayo, nezvimwe. .

Midziyo yedu yechokoreti yave yakakurumbira muindasitiri yezvekudya.Panguva imwecheteyo, zvigadzirwa zvinogadzirwa nemidziyo yedu zvakare zviri pamberi peindasitiri yemapipi zvakare.Kunze kwemusika wepamba, zvishandiso zvedu zvakatengeswa zvakanyanya kuGermany, India, Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel, Peru nedzimwe nyika dzakawanda pasirese.

Isu tinopa OEM sevhisi.Panguva imwecheteyo, hupenyu-yenguva-yekupedzisira-yekutengesa sevhisi yemidziyo yedu inopihwa pasi rese mutengi uye isu tiri kutarisira kushanya kwako.

Masevhisi Edu

Pre-sale Services

1. Tichakutungamirira kuti usarudze michina yakakodzera yeprojekti yako.

2. Kana kusaina chibvumirano, isu tichazivisa magetsi emagetsi uye frequency.

3. Yakasimba nekuedzwa kwakakwana uye kugadzirisa zvakanaka maererano nezvinodiwa nevatengi vasati vatumirwa.

Mushure mekutengesa Service

1. Basa rehunyanzvi rakapihwa.

2. Kuiswa uye On-saiti kudzidziswa sevhisi yakapihwa.Debugger chete debug uye dzidzisa mhando mbiri dzezvigadzirwa.Mari yekuwedzera inobhadhariswa kune zvimwe zvigadzirwa.Kuisa uye kubhadharisa vanaMazvikokota zvinosanganisira matikiti ekuenda nekudzoka, traffic yemukati menyika, pokugara uye muripo weboarding zviri kuakaundi yoMutengi.Mari yebasa yeUSD 60.00/zuva panyanzvi inoshanda.

3. Gore rimwe waranti yekushanda kwakajairika.Hupenyu-yenguva tekinoroji rutsigiro rwakapihwa.

Muripo wesevhisi unoshanda kana ukashaikwa zvisirizvo kana kukuvadzwa.

1. Kubhadhara: T / T mberi.40% yekubhadhara pasi, 60% inopesana nekugamuchirwa kubva kune vatengi

2. Yakasimba nekuedzwa kwakakwana uye kugadzirisa zvakanaka maererano nezvinodiwa nevatengi vasati vatumirwa.

3. Kugadzirisa kunowanikwa.

5. Ndeapi ruzivo rwandinofanira kukuzivisa iwe kana ndichida kuwana quotation yakazara?

Bag mhando, saizi, uremu hwezvinhu, rudzi rwezvinhu, ukobvu, kudhinda, mavara, huwandu

6. Patinenge tichigadzira dhizaini yedu yemifananidzo, rudzii rwechimiro chinowanikwa kwauri?

Iyo yakakurumbira fomati: AI, JPEG, CDR, PSD, TIF

7. Chikwama chemapuranga chakazara nemuchina uye Chirungu manule

8. Transformer inopiwa

9. Technical manual muChirungu inopiwa

10. Muchina isimbi isina tsvina

11. Mumutsara wekutumira kunze kurongedza zvinhu