I-Nut Chocolate Belt Coating System With 500L Uhlelo Lokudla

●Isingeniso Somkhiqizo

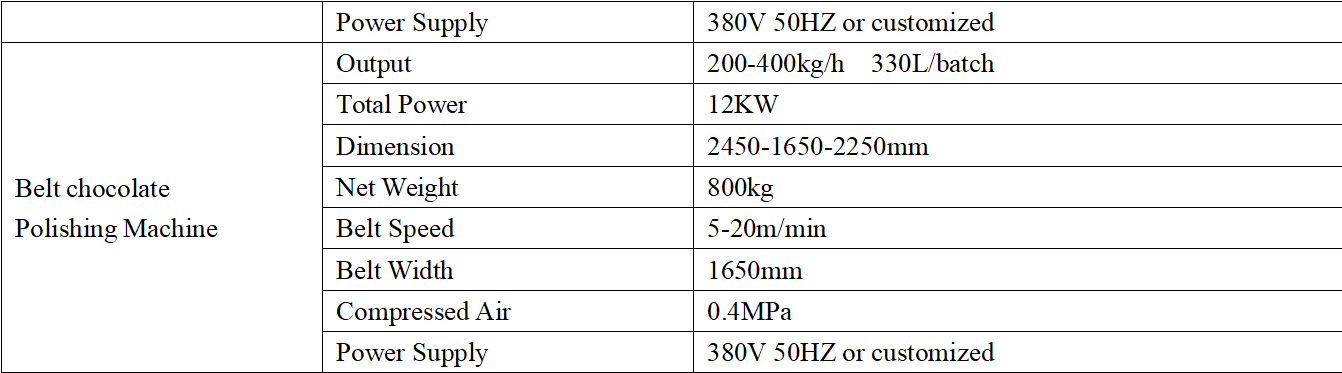

Iyunithi yomshini wokugcwalisa ushokoledi

A. I-Adopts PLC system, ingagcina zonke izinhlobo zefomula yomkhiqizo futhi ilawule ngokuzenzakalelayoepheleleinqubo yokukhiqiza.

B. Umthamo wokufafaza nesikhathi sokufutha singasethwa ngokufanele emikhiqizweni eyahlukene.

C. Ibhande le-PV lezinga elidliwayo.Izinto zokugcwalisa zizojikeleza ngesivinini esikhulu ebhandeni.

D. Isisindo sikagesi sizokala ngokuzenzakalelayo izinto ngokwefomula yomkhiqizo.

E. Okuzenzakalelayo okugcwelekuyahlelekaukulawula.

F. I-Automatic Feeding System eyinhloko iqukethe Ithangi Lokugcina Likashokoledi, Iphampu Ye-Chocolate Slurry kanye nepayipi Lokufaka Insimbi Engenasici.

Umshini we-G. usebenzisa isistimu yokulawula i-DELTAfuthi Siemensizingxenye ze-elekthronikhi.

H. Isikrini sokuthinta esingu-10 intshi

I. Ulimi Olutholakalayo: IsiNgisi nesiRashiya

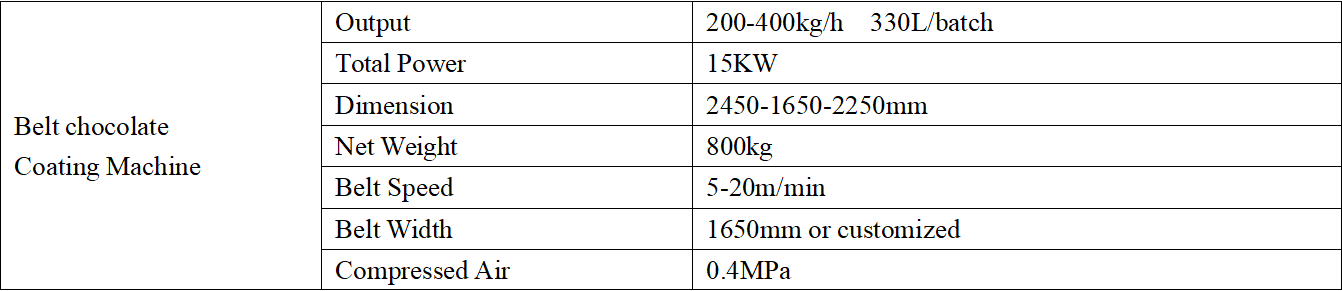

Iyunithi yomshini wokupholisha ushokoledi

I-1.Umshini wonke usebenzisa ukulawula uhlelo lwe-PLC, futhi inqubo yokukhiqiza ihlelwe ilawulwa.

2.Ibhande le-conveyor lenziwe ngezinto zebanga lokudla le-PV.Imikhiqizo yokupholisha izungeza ngesivinini esikhulu ngokusebenza kwebhande le-chain plate conveyor, futhi ngokulawula uhlelo, uwoyela wokupholisha uzofutha ngokuzenzakalelayo nangokulinganayo endaweni yomkhiqizo.

3.Ngokwezicelo ezihlukene zamasu okukhiqiza, izinto zokusebenza zingasethelwa isikhathi sokupholisha esihlukene, izikhathi zokupholisha amafutha, umthamo wamafutha wokupholisha, kanye nesivinini esihlukile sebhodi leketanga ngezigaba ezahlukene.

4.Kukhona ukushintsha phakathi komoya obandayo noshisayo ngesikhathi sokupholisha.Izinto zokusebenza zingahlangabezana nezidingo zobuchwepheshe zesikhathi sokupholisa semikhiqizo ehlukene.

5.DELTA Control system,10 inch Touch Screen,Siemens electronic components.Language Iyatholakala: IsiNgisi nesiRashiya.

●Ividiyo