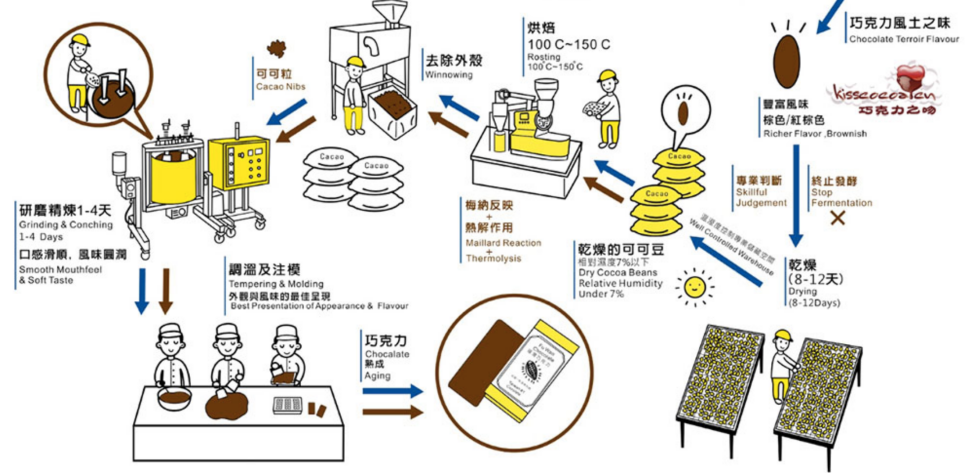

Ubhontshisi we-cocoa omisiwe ngelanga uthunyelwa embonini, uqala ngokusemthethweni uhambo lwayo lokuguqulwa ... Kusuka kubhontshisi obabayo kuya kushokoledi omnandi, uchungechunge lwezinqubo zokucubungula luyadingeka.Ngokwenqubo yokucubungula, ingahlukaniswa cishe ngezinqubo ezi-3, i-pulping Pressing, ukugaya kahle nokucwenga, ukulungiswa kwezinga lokushisa nokubumba.

Manje, izindawo eziningi emhlabeni zisagcina indlela yasekuqaleni yokucubungula ubhontshisi we-cocoa ngokuzenzisa, kodwa owenziwe ngezandla kusuka kubhontshisi kakhokho kuya kushokoledi, ukunambitheka kuzoba lukhuni.Ngakho lesi sihloko sikhuluma ngokuyinhlokoindlela yokusebenzisa imishini ukuqedela lolu chungechunge lokucubungula

1. Ukugaya kanye Pukuhlehlisa

Ubhontshisi we-cocoa uyachotshozwa futhi ucindezelwe ukuze kutholakale utshwala be-cocoa, ibhotela le-cocoa, ne-cocoa powder.

Ngaphambi kokucofa nokucindezela, kufanele kudlule ohlelweni lokukhetha ubhontshisi, ukuwasha, ukuwoswa, ukwela nokugxotshwa.Ukukhetha ubhontshisi, njengoba negama liphakamisa, wukuhluza ubhontshisi we-cocoa ongafanelekile noma owonakele.Geza ubhontshisi, hlambulula futhi womise.Bese uqala ukubhaka, ukwela, ukuchoboza, nokugaya kahle ukuze uthole ugologo we-cocoa, bese kuthi inqwaba yotshwala be-cocoa ipholiswe ukuze kutholakale inqwaba yotshwala be-cocoa.Utshwala be-cocoa bucindezelwa ngomshini wokunyathelisa uwoyela ukuze kukhishwe ibhotela likakhokho.I-cocoa powder iyikhekhe le-cocoa elihlala ngemva kokuba uketshezi lwe-cocoa lukhanyiwe ukuze kukhishwe amafutha, bese lichotshozwa, ligaywe, futhi lihlungwe ukuze kutholwe impushana ebomvu ngokunsundu.

1.1 Ukubhaka - Umshini Wokushisisa I-cocoa

Ubhontshisi kakhokho wosiwe emazingeni okushisa aphezulu aphakathi kuka-100 no-120°C.Yonke inqubo ithatha imizuzu engu-30 ukuqinisekisa ukuthi ubhontshisi we-cocoa ngamunye ukhipha ukunambitheka okucebile kwe-cocoa ngemva kokugazinga.

1.2 Ukwela nokuchoboza - Umshini Wokuqhekeka Ukhokho & Wokonela

Ngemva kokuwugazinga, ubhontshisi we-cocoa uba mnyama ngombala, usondele kumbala onsundu omnyama kashokoledi ngokwawo.Ubhontshisi kakhokho uphola ngokushesha, futhi amagobolondo azacile ashwabene kakhulu ngesikhathi sokugazinga kufanele akhishwe, okudinga ukuthi abalandeli baphephethe izikhumba.Ama-nibs, ingxenye esebenzisekayo kabhontshisi we-cocoa, ashiywe futhi agaywe abe yizingono.Lesi sinyathelo sibizwa ngokuthi ukwela nokuchoboza, futhi kunezindlela eziningana ezihlukene, okuwubuqili kunazo zonke ukuqeda isikhumba ngokuphelele ngaphandle kokulahlekelwa ubhontshisi ophansi.Uma kunesikhumba esinenkani esihlanganiswe noshokoledi, sizoletha ukunambitheka.

Le nqubo ingenziwa futhi esigabeni sokuqala sokugazinga ngaphambi kokugazinga.Wonke ubhontshisi udinga ukugaywa endaweni engu-400 ° C imizuzwana engu-100, ukuze ubhontshisi we-cocoa kube lula ukukhipha isikhumba sikabhontshisi ngemva kwale nqubo.Khona-ke igaywe ibe yizinhlamvu ezincane kakhulu, noma yiziphi izikhumba ze-cocoa zikhishwa kule nqubo, ngaphambi kokuba zithosiwe.

Emafekthri amaningi, le nqubo yenziwa "nge-fan crusher", umshini omkhulu ophephula ama-hulls.Umshini udlulisa ubhontshisi kuma-cones ama-serrated ukuze aphuke kunokuchotshozwa.Phakathi nenqubo, uchungechunge lwezisefo eziwumshini zihlukanisa izingcezu zibe izinhlayiya ezinosayizi abahlukene kuyilapho abalandeli bephephetha igobolondo elingaphandle elincanyana lisuke kuma-pulpy bits.

1.3 Ukugaya kahle - I-Colloid Mill&Melanger

Embonini yesimanje kashokoledi, ungakhetha ukusebenzisa isigayo se-colloid noma isigayo samatshe ukuze ugaye ubhontshisi ochotshoziwe ube yi-slurry.

Umgomo wokusebenza kwesigayo se-colloid ukugunda, ukugaya, nokushukumisa ngesivinini esikhulu.Inqubo yokugaya yenzeka ngokuhambisana phakathi kwamazinyo amabili, elinye lizungeza ngesivinini kanti elinye lihlala limile.Ngaphezu kokudlidliza kwe-high-frequency kanye ne-high-speed eddy current, into ephakathi kwamazinyo nayo ingaphansi kokugunda okuqinile nokuguga.Impahla izohluzwa ngokulinganayo, ihlakazwe futhi ifakwe emulsified.

Izigayo zamatshe zisebenzisa amarola egwadle amabili ukugaya okuqhubekayo.Ibhotela likakhokho eliqukethwe kubhontshisi kabhontshisi kakhokho nalo likhululwa kancane ngemva kokugaywa kahle phakathi nesikhathi eside sokugingqika okunganqamuki, okwenza udaka lwesigaba esiwugqinsi, olujiya lube yizigaxa ngemva kokupholisa.

Eqinisweni, uma kuziwa esiteji sokugaya nokucwenga, akuyona into engaphezu kokushintsha "i-blender yokugaya" engcono kakhulu yokugaya okuqhubekayo.

Ibhotela likakhokho lisebenza njengesithambiso njengoba ushukela ne-cocoa powder kugaywa kube yizinhlayiya ezincane.Umlomo womuntu unganambitha izinhlayiya ezinkulu kune-20 microns.Njengoba wonke umuntu ethanda ukujabulela ushokoledi oshelelezi kakhulu futhi ocebile, kufanele siqinisekise ukuthi zonke izinhlayiya zezinto ezikushokoledi zincane kunalo sayizi.Okusho ukuthi, i-cocoa powder kufanele igaywe ibe ngaphansi kwama-microns angu-20, okuyisinyathelo esilandelayo sokucwenga nokucwenga, ngakho-ke idinga ukuqhubeka nokugaya isikhathi eside.

I-Melanger

I-Colloid Mill

1.4 Umshini Wokukhipha Uwoyela Wokucindezelwa Nomshini Wokugaya Impushana

Ibhotela le-cocoa kanye ne-cocoa powder iqukethe uketshezi lwe-cocoa noma uketshezi lwe-liquid olukhiqizwa ngemva kwe-pulping, okudingeka lukhishwe ngokucindezela.Khama ugologo we-cocoa ukuze uhlukanise ibhotela le-cocoa, elinamafutha angu-100%, bese ugaya ikhekhe likabhontshisi elisele ukwenza i-cocoa powder, nge-fat content 10-22%.

Faka uketshezi lwe-cocoa emshinini wokunyathelisa wamafutha othomathikhi, futhi uzophakanyiswa ngepiston yesilinda samafutha, futhi uwoyela uzogeleza uphume esikhaleni sokubhoboza, bese ungena emgqonyeni kawoyela ngepuleti lokwamukela uwoyela ukuze ugcine uwoyela.

Kunamasethi amaningana emimese enyakazayo (noma ama-prism noma amakhanda esando) esondweni elijikelezayo ngaphakathi kwesigayo, kanye nesethi yemimese engashintshi egiyeni leringi.Ngesikhathi sokungqubuzana kokusika phakathi kommese ohambayo kanye nommese omisiwe, izinto ezibonakalayo zichotshozwa.Ngesikhathi esifanayo, igumbi lokuchoboza likhiqiza ukugeleza komoya, okukhipha ukushisa kanye nomkhiqizo ophelile ovela esikrinini.

2. Ukucwenga-Chocolate Conching Machine

Ekuphishekeleni ushokoledi omnyama omsulwa, awudingi ukwengeza noma yiziphi izinto ezisizayo, ngisho noshukela oyisisekelo, kodwa lokhu ukukhetha kwedlanzana phela.Ngaphandle kwe-cocoa mass, ibhotela le-cocoa kanye ne-cocoa powder, ukukhiqizwa kukashokoledi othandwayo nakho kudinga izithako ezifana noshukela, imikhiqizo yobisi, i-lecithin, ama-flavour kanye nama-surfactants.Lokhu kudinga ukucwengwa nokucwengwa.Ukugaya nokucwenga empeleni kuwukuqhubeka kwenqubo yangaphambilini.Nakuba ubuhle bezinto zikashokoledi ngemva kokugaya sekufinyelele imfuneko, ayigcotshiwe ngokwanele futhi ukunambitheka akugculisi.Izinto ezihlukahlukene azikakahlanganiswa ngokugcwele zibe ukunambitheka okuyingqayizivele.Okunye ukunambitheka okungajabulisi kusekhona, ngakho-ke kudingeka ukucolisiswa okwengeziwe.

Lobu buchwepheshe basungulwa nguRudolph Lindt (umsunguli weLindt 5 grams) ngasekupheleni kwekhulu le-19.Isizathu esenza kuthiwe "Conching" ingoba ekuqaleni bekuyithangi eliyindilinga elimise okwegobolondo lekhonsathi.I-conch (i-conche) ibizwa ngokuthi "concha", okusho ukuthi igobolondo.Izinto eziwuketshezi zikashokoledi ziphendulwa ngokuphindaphindiwe yi-roller isikhathi eside ethangini elinjalo, ukusunduza nokuhlikihla ukuze kutholwe ukuthambisa okuthambile, ukuhlanganiswa kwephunga kanye nokunambitheka okuyingqayizivele kwe-flavour, le nqubo ibizwa ngokuthi "ukugaya nokucwenga"

Ngenkathi kucwengwa, kungangezwa izinto ezisizayo ezahlukahlukene.

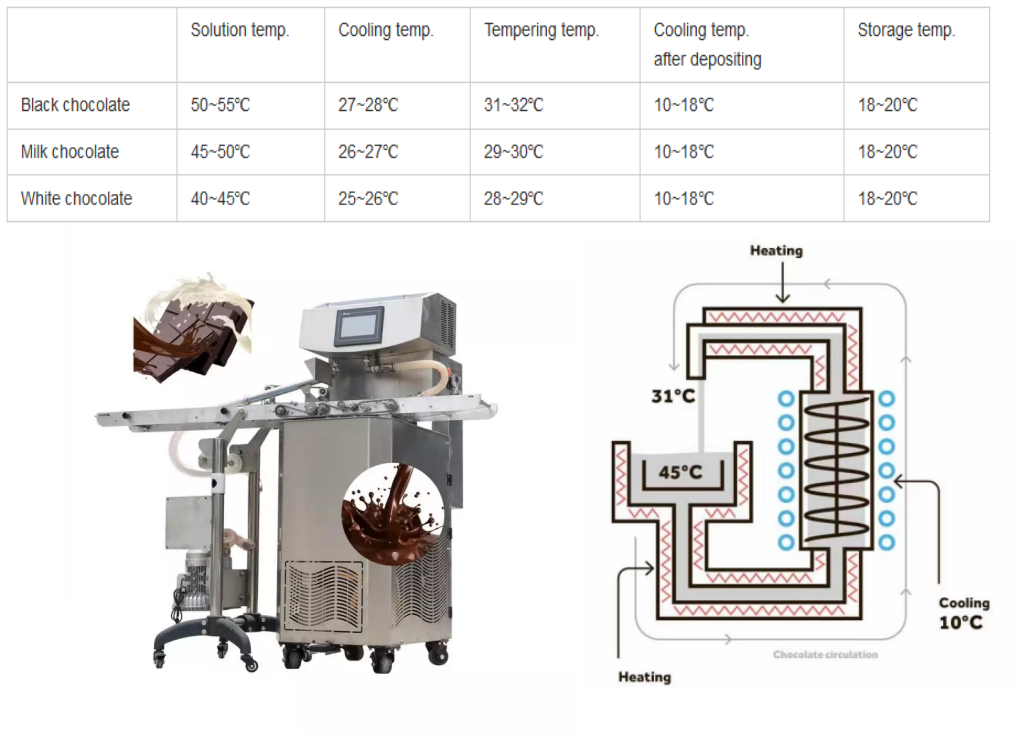

3.I-Temper&Moulds-Tempering Machine&Moulding

I-Tempering iyisinyathelo sokugcina ekukhiqizeni futhi inomthelela omkhulu ekuhlangenwe nakho kokugcina kukashokoledi kubathengi.Ingabe uke waba noshokoledi owawudabukile futhi unefilimu emhlophe e-opaque ngaphandle?Kungenzeka ukuthi ukuthambisa akwenziwanga kahle noma kukhona okungalungile ngezithako.

Ukuze ufinyelele phansi lo mbuzo, udinga ukwazi izinto ezimbalwa mayelana nebhotela le-cocoa.Ibhotela le-cocoa libalelwa ku-48% -57% wesisindo sikabhontshisi we-cocoa.Yinto eyenza ushokoledi ungancibiliki esandleni (uqinile ekamelweni lokushisa) uncibilike kuphela emlonyeni (uqala ukuncibilika ekushiseni komzimba).Ukubeka ucezu lukashokoledi olimini lwakho futhi uzizwe uncibilika kancane kancane emlonyeni wakho ezinye zezimfanelo eziheha kakhulu zikashokoledi, futhi konke kungenxa yebhotela likakhokho.

Ibhotela likakhokho liyi-polymorphic, okusho ukuthi, ngaphansi kwezimo ezihlukene zokuqiniswa, lakha izinhlobo ezahlukene zamakristalu, okungenzeka azinzile noma angazinzile.Amakristalu azinzile apakishwe eduze futhi anamaphuzu aphezulu ancibilika kunamakristalu angazinzile.Ngakho-ke, kufanele silungise izinga lokushisa ukuze siqinisekise ukuthi ibhotela le-cocoa nebhotela le-cocoa-like ifomu le-crystal ezinzile kakhulu, bese lipholisa ngendlela efanele ukuze ushokoledi ube nokucwebezela okuhle futhi ungaqhakazi isikhathi eside.Ngokuvamile indlela yokushisa ushokoledi ihlanganisa izinyathelo ezilandelayo

1. Ncibilikisa ushokoledi ngokuphelele

2. Kuphole endaweni yezinga lokushisa elicwebezelayo

3. Khiqiza i-crystallization

4. Ncibilikisa amakristalu angazinzile

Izinga lokushisa lingalungiswa ngesandla, kodwa izinga lokushisa kufanele libe elinembile.Ukukhetha umshini wokushisa ushokoledi olawula ngokunembile izinga lokushisa ukuya kumehluko wezinga lokushisa ongaphansi kuka-±0.2 kungakusiza kahle kakhulu.Ukushisa kwamashokoledi ahlukene nakho akuhambelani ngokuphelele:

Uma i-sauce ye-chocolate isifakwe kahle, kufanele ibunjwe ngokushesha, bese ipholisa ukuze ilungise isakhiwo futhi iguqule ibe yisimo esiqinile esiqinile.Ingathululwa ngesandla noma ngomshini.Ukuthululelwa isikhunta ngokuzenzela akunembile njengokuthelwa komshini, ngakho isoso eyeqile idinga ukusulwa.Ngemva kokupholisa, ingasuswa ibe ushokoledi omuhle.

Isikhathi sokuthumela: Nov-28-2022