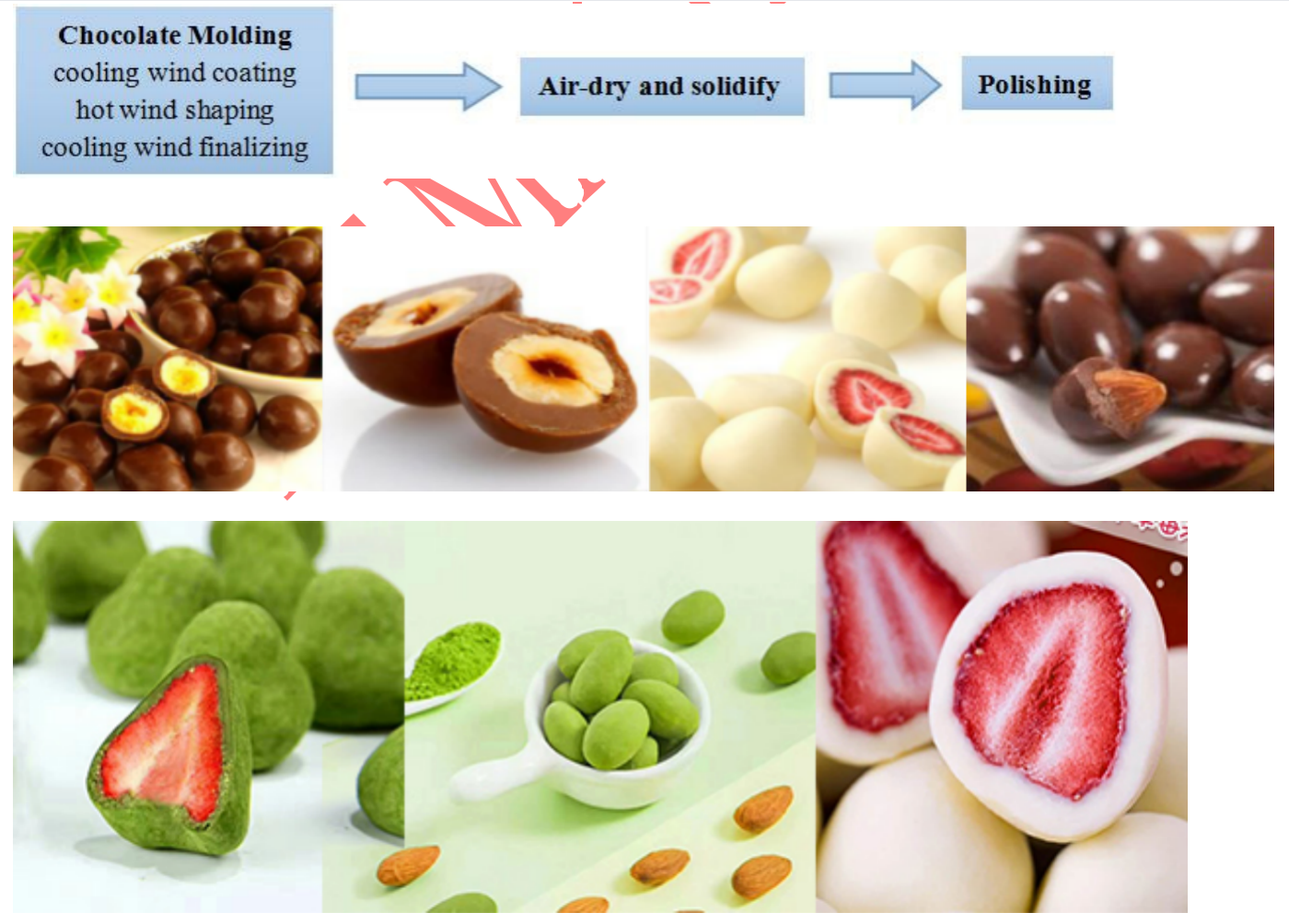

TlhahisoProcess

Bakeng sa seaparo sa chokolete ka kopo ikopanyesuzy@lstchocolatemachine.com, kea leboha, re na le mochine ho tloha lab ho ea fekthering, 6kg-1000kg ka batch.

1. Lebanta la TsokolateHo roalaMochini

* Ho roala lebanta la chokolete le mochini oa ho bopa

*Sistimi ea ho fepa lintho tsa chokolete

* Litsi tsa lihatsetsi tsa indasteri tse 7P (setsi sa ho pholisa metsi le moea o pholileng)

2.Dry Storage(ka moreki)

Kamore e arohaneng e hloka ho feta 15㎡, mocheso o tlase le mongobo.Tsokolate e tla beoa ka kamoreng hoo e ka bang

Lihora tse 8-10 ho tlosa mongobo le ho tiisa.E tla eketsa ho benya le nako ea sethala sa chokolete.Bareki ba eletsoa

ho kenya sehlahisoa ka pallet e nyane ebe o beha lishelefong tsa multilayer.

3.Chocolate polishingMachine

* Mochini o benyang Lebanta la Chokolete

* Sistimi ea sehatsetsi sa indasteri ea 7P

4.Bakeng saSe khethehilengPtsela

1.kapa lihlahisoa tse senyehang le sehlahisoa se ikhohomosang, Diameter ≥4mm, thepa e pentiloeng ≤250 litres.Ha e ntse e senyeha habonolo, thepa e fokotseha.

2. Bakeng sa lihlahisoa tse nang le sekhutlo le metshetshe, sebopeho se chitja le botenya bo ts'oanang ha bo khothaletsoe.

3.Bakeng sa sehlahisoa sa sekhomaretsi, beha lintho tse fokolang tse khomarelang.Haeba lisebelisoa li khomarelana 'me li etsa sebopeho.

4. Bakeng sa peista ea chokolete, ho hlokahala hore u sefa pele u kenya ho qoba boloko ba molomo oa spray.

5.Main Features & Melemo

1.Tlhahiso e ikemetseng, boloka basebetsi / katleho e phahameng ea tlhahiso / tlhahiso e kholo.

2.Full othomathike ho fepa chokolete, ho roala le ho bopa.

3.Auto weighting le auto switching bakeng sa moea o chesang le moea o batang.

Ts'ebetso ea tlhahiso ea 4.Programmed e etsa sehlahisoa

5.Chocolate atomized spray le ho tšela e kopana le litlhoko tse khethehileng tsa lihlahisoa tse fapaneng.

Nako ea poso: Oct-18-2021