Yemutengo wakanaka tafura-yepamusoro confectionery depositor inowedzera zvinoshamisa machokoreti, gummies, caramel, hard candy depositing.Yakagadzirirwa kuzadza polycarbonate / silicone molds kana chocolate shells ne fluid ganache, nougat, couverture kana liquor.Deposit pamutsara mumwe panguva ine chaiyo dose yezvigadzirwa kune giramu.

Iyo inopisa pistons uye inopisa hopper ine inogadziriswa tembiricha kutonga kuti ubudirire kuisa zvese zvakakwirira uye zvakaderera kupisa ingredients.Cavity mold volume inogadziriswa uye nozzles inogona kurongeka kuti igare zvakanaka mold yako.

Contact nzira:008615528001618

email:suzy@lstchocolatemachine.com

www.lstchocolatemachine.com

5.Mainfeatures

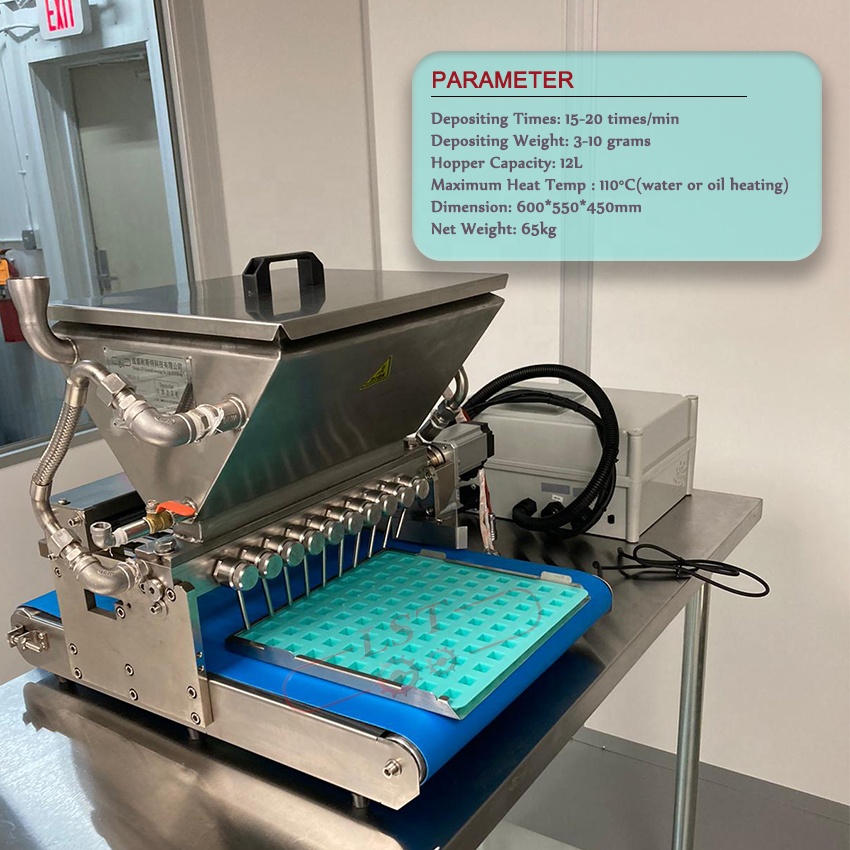

Compact, nzvimbo yekuchengetedza tafura yepamusoro dhizaini

10 pistons inosanganisirwa ine inogadziriswa & inobvisika nozzles

(unogona kuhodha zvimwe)

simbi isina tsvina XL hopper ine chivharo

mabhora esimbi asina tsvina

aluminium pallet mutakuri

kuchenesa mabhurashi

spare o-rings

PLC control deposit

Servo injini

6.Kuisa nguva: 15-20 nguva / min

Kuisa uremu: 3 kusvika 10 gramu

Hopper kugona: 12L

Mvura yekudziya system uye inochinja tembiricha kutonga

Simba rekuisa: 110/220V AC 50-60Hz

Simba rinobuda: 24V DC / max.1500W

zvinhu: SSS304

Kupisa kukuru:110°C

Nozzles nhamba: 10pcs

Saizi yemuchina (L * W * H): 600 * 550 * 450mm

Kurema: 65 kg

Pallet mutakuri anosanganisira

Disassembly pasina midziyo yekuchenesa

CE Certified

Inogona kuodha additonl pistons, nozzles, spare parts etc.

Inokurudzirwa kupisa: 30 ℃ yechokoreti, 65 ℃ yemagummies

Mold kushandiswa: upamhi mukati 410mm

7.Operation process

2.1 Isa zviumbwa pabhandi pabhuku rekushandisa;

2.2 Tanga kuburitsa bhandi, ita chokoreti ichiisa imwe neimwe pane otomatiki.

Cherechedza:

3.1 Ndokumbira uburitse plug huru uye wozobvisa chinhu chekudziya usati wabvisa kuchenesa michina.Ita shuwa kuti plug yakaoma paunotanga mudziyo;

3.2 Ndokumbira ubvise utachiona uye woomesa chokoreti yekubata nhengo usati washandisa mudziyo.

Nguva yekutumira: Mar-23-2022