Iro zuva-yakaomeswa cocoa bhinzi inotumirwa kufekitari, kutanga zviri pamutemo rwendo rwayo rwekushandura ... Kubva pabhinzi inovava kusvika kune chokoti inonaka, hurongwa hwekugadzirisa hunodiwa.Zvinoenderana nemaitiro ekugadzirisa, inogona kukamurwa kuita 3 maitiro, pulping Kudzvanya, kukuya kwakanaka uye kunatsa, kugadzirisa tembiricha uye kuumba.

Ikozvino, nzvimbo zhinji munyika dzichiri kuchengetedza nzira yekutanga yekugadzira cocoa bhinzi, asi yakagadzirwa nemaoko kubva kucocoa bhinzi kuenda kuchokoreti, kuravira kuchave kwakashata.Saka chinyorwa ichi chinonyanya kutaura nezvemashandisiro emichina kupedzisa iyi nhevedzano yekugadzirisa

1. Kukuya uye Pressing

Cocoa bhinzi dzinopwanyika uye kudzvanywa kuti pawane cocoa liquor, cocoa butter, uye cocoa powder.

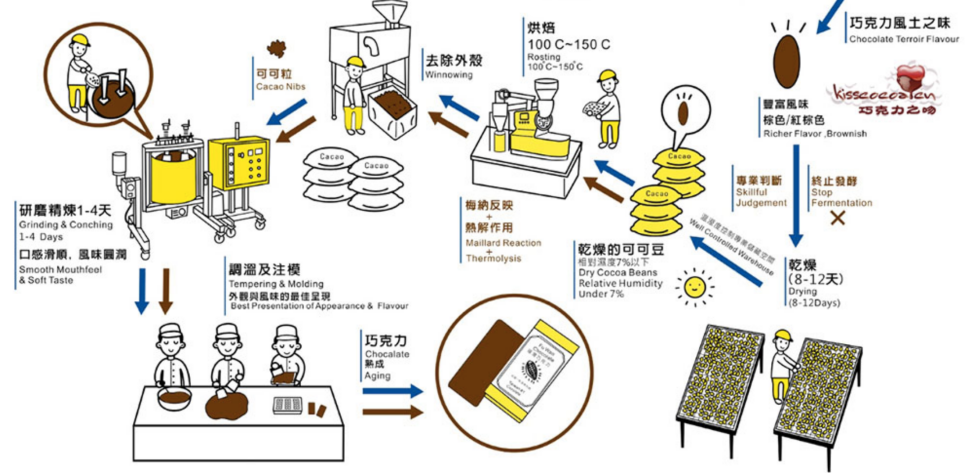

Isati yapuruzira nekudzvanya, inofanira kupinda muchirongwa chekusarudza bhinzi, kugeza bhinzi, kugocha, kuurutsa nekupwanya.Sarudzo yebhinzi, sekureva kunoita zita, ndeyekuvheneka bhinzi dzekoko dzisina kukodzera kana dzakaora.Geza bhinzi, sukurudza uye woomesa.Wobva watanga kubheka, kuhwihwidza, kupwanya, nekugaya zvakanaka kuti uwane cocoa doro, uye iyo cocoa liquor mass inotonhodzwa kuti uwane cocoa liquor mass.Iyo cocoa doro inotsikirirwa kuburikidza nemuchina wemafuta kuti ubvise cocoa butter.Kocoa poda ndiyo keke yecocoa inosara mushure mekunge cocoa liquid yasvinwa kubvisa mafuta, yobva yapwanywa, kukuyiwa, uye kusefa kuti uwane hupfu hutsvuku.

1.1 Kubika - Cocoa Roaster Machine

Cocoa bhinzi dzinogochwa patembiricha yepamusoro iri pakati pe100 ne120°C.Kuita kwese kunotora maminetsi makumi matatu kuve nechokwadi chekuti cocoa bhinzi yega yega inoburitsa yakapfuma yecocoa flavour mushure mekugocha.

1.2 Kupepeta nekupwanya - Cocoa Kutsemukira &Kuhwinha Muchina

Mushure mekugocha, bhinzi yecocoa inova yakasviba muvara, padyo neyakasvibira ruvara rwechokoreti pachayo.Cocoa bhinzi dzinotonhora nekukasika, uye matehwe matete anofenda panguva yekugochwa anofanira kubviswa, zvoda kuti mafeni afuridzire matehwe.Iyo nibs, iyo inogona kushandiswa yecocoa bean, inosiiwa uye inogayiwa kuita nibs.Iyi nhanho inonzi kuhwisa nekupwanya, uye kune nzira dzakasiyana siyana, dzakaomarara dziri kubvisa ganda zvachose pasina kurasikirwa nebhinzi.Kana pane ganda rakasindimara rakasanganiswa nechokoti, rinounza kunhuhwirira.

Iyi nzira inogonawo kuitwa mu pre-roasting stage isati yagocha.Bhinzi dzose dzinoda kugochwa munzvimbo ye400 ° C kwemasekonzi zana, kuitira kuti cocoa bhinzi zvive nyore kudurura ganda rebhinzi mushure mekuita uku.Iyo inobva yapwanyika kuita zviyo zviduku zvikuru, chero matehwe ecocoa anobviswa mukugadzirisa, asati agochwa.

Mumafekitori mazhinji, kuita uku kunoitwa ne "fan crusher", muchina muhombe unofuridza mabhurugwa.Muchina uyu unopfuudza bhinzi nemuma serrated cones kuitira kuti atyoke kwete kupwanywa.Mukati mekuita, nhevedzano yemasefa emuchina anopatsanura zvimedu kuita zvidimbu zvehukuru hwakasiyana ukuwo mafeni achifuridzira goko rakatetepa rekunze kubva kune pulpy bits.

1.3 Kukuya - Colloid Mill&Melanger

Mufekitari yechokoreti yemazuva ano, unogona kusarudza kushandisa chigayo checolloid kana chigayo chematombo kukuya bhinzi yakapwanyika kuita slurry.

Nheyo yekushanda yechigayo checolloid ndeyekuveura, kukuya, uye nekumhanyisa-kumhanyisa.Kukuya kunoitika mukufamba kuri pakati pemazino maviri, rimwe richitenderera nekumhanya kukuru asi rimwe richiramba rakamira.Mukuwedzera kune-high-frequency vibration uye high-speed eddy current, zvinhu zviri pakati pemazino zvinoiswawo kune shear yakasimba uye kupfeka.Izvo zvinhu zvichave zvakaenzana, zvakaparadzirwa uye emulsified.

Zvigayo zvematombo zvinoshandisa magranite roller maviri kuti arambe achikuya.Iyo cocoa butter iri mucocoa bean nibs inoburitswawo zvishoma nezvishoma mushure mekugadzirwa yakatsetseka mukati menguva yakareba yekuumbururuka, ichiita gobvu chikamu slurry, icho chinobatana kuita mapundu mushure mekutonhora.

Muchokwadi, kana zvasvika padanho rekukuya nekunatsa, hachisi chimwe chinhu kunze kwekuchinja kuita "grinding blender" yekuramba ichikuya.

Cocoa butter inoshanda semafuta sezvo shuga necocoa poda zvinogayiwa kuita zvidimbu zvidiki.Muromo wemunhu unogona kuravira zvimedu zvakakura kudarika 20 microns.Sezvo munhu wese achida kunakidzwa nechokoreti yakatsetseka uye yakapfuma, isu tinofanirwa kuve neshuwa kuti zvese zvimedu zviri muchokoreti zvidiki pane saizi iyi.Izvi zvinoreva kuti, iyo cocoa poda inofanira kunge yakadzika kusvika pasi pe20 microns, inova danho rinotevera rekunatsa nekunatsa, saka inoda kuramba ichikuya kwenguva yakareba.

Melanger

Colloid Mill

1.4 Kubvisa-Oiri Dhinda Muchina & Poda Kukuya muchina

Kocoa bhotela uye cocoa poda ine cocoa fluid kana mvura yakawanda inogadzirwa mushure mekuputika, inoda kuburitswa nekudzvanya.Sveta cocoa doro kuti uparadzanise cocoa bhotela, ine mafuta ane 100%, wobva wakuya bhinzi yakasara kuti uite cocoa powder, nemafuta e10-22%.

Isa iyo cocoa mvura muotomatiki mafuta muchina, uye inosimudzwa nepiston yehumburumbira yeoiri, uye mafuta anoyerera achibuda kubva pakakoromoka, opinda mubhodhoro remafuta kuburikidza nendiro yekugamuchira mafuta kuchengetedza mafuta.

Kune akati wandei seti ekufambisa mapanga (kana prisms kana sando misoro) muvhiri rinotenderera mukati meguyo, uye seti yemapanga akagadzika mugiya remhete.Munguva yekucheka kwekucheka pakati pebanga rinofamba uye banga rakagadziriswa, zvinhu zvinopwanyika.Panguva imwecheteyo, kamuri rekupwanya rinoburitsa mhepo, iyo inoburitsa kupisa pamwe chete nechigadzirwa chakapedzwa kubva pachiratidziri.

2. Kunatsa-Chocolate Conching Machine

Mukutsvaga chokoreti yakasviba yakachena, haufanire kuwedzera chero zvigadzirwa zvekubatsira, kunyangwe iyo yakanyanya shuga, asi iyi ndiyo sarudzo yevashoma mushure mezvose.Pamusoro pecocoa mass, cocoa butter uye cocoa poda, kugadzirwa kwechokoreti kwakakurumbira kunodawo zvinongedzo zvakaita seshuga, zvigadzirwa zvemukaka, lecithin, zvinonhuhwirira uye surfactants.Izvi zvinoda kunatswa nekunatswa.Kukuya nekunatsa ndiko kuenderera mberi kwemaitiro apfuura.Kunyangwe kunaka kwechokoreti zvinhu mushure mekugaya kwasvika pazvinodiwa, haina kuzorwa zvakakwana uye kuravira hakusi kugutsa.Zvishandiso zvakasiyana-siyana hazvisati zvanyatsobatanidzwa kuita flavour yakasarudzika.Kumwe kuravira kusingafadzi kuchiripo, saka kumwe kunatswa kunodiwa..

Iyi tekinoroji yakagadzirwa naRudolph Lindt (muvambi weLindt 5 gramu) mukupera kwezana ramakore rechi 19.Chikonzero nei ichinzi "Conching" imhaka yekuti pakutanga raive tangi redenderedzwa rakaita segoko rekoni.Iyo conch (conche) inodanwa kubva kuSpanish "concha", zvinoreva kuti goko.Iyo chokoreti yemvura zvinhu inotenderedzwa uye yadzokororwa ne roller kwenguva yakareba mutangi rakadaro, ichisundidzira uye nekukwesha kuti iwane yakapfava lubrication, inonhuhwirira fusion uye yakasarudzika kuravira kuravira, maitiro aya anonzi "kukuya uye kunatsa"

Paunenge uchikwenenzvera, zvinhu zvakasiyana-siyana zvekubatsira zvinogona kuwedzerwa.

3.Mhasha&Moulds-Tempering Machine&Moulding

Tempering inhanho yekupedzisira mukugadzira uye ine simba guru pane yekupedzisira chocolate ruzivo kune vatengi.Wakambova nechokoreti yakanga yakashata uye iine opaque chena firimu kunze?Pamwe kushatirwa hakuna kuitwa nemazvo kana kuti chimwe chinhu chaive chisina kumira zvakanaka pamidziyo yacho.

Kuti usvike pazasi pemubvunzo uyu, unofanirwa kuziva zvinhu zvishoma nezve cocoa butter.Kocoa butter inosvika 48% -57% yehuremu hwecocoa beans.Ndicho chinhu chinoita kuti chokoreti isanyungudika muruoko (yakasimba patembiricha yekamuri) inonyungudika chete mumuromo (inotanga kunyunguduka pakupisa kwemuviri).Kuisa chimedu chechokoreti parurimi rwako uye kuinzwa ichinyunguduka zvishoma nezvishoma mumuromo mako ndeimwe yemhando inonyengerera yechokoreti, uye zvese nekuda kwecocoa butter.

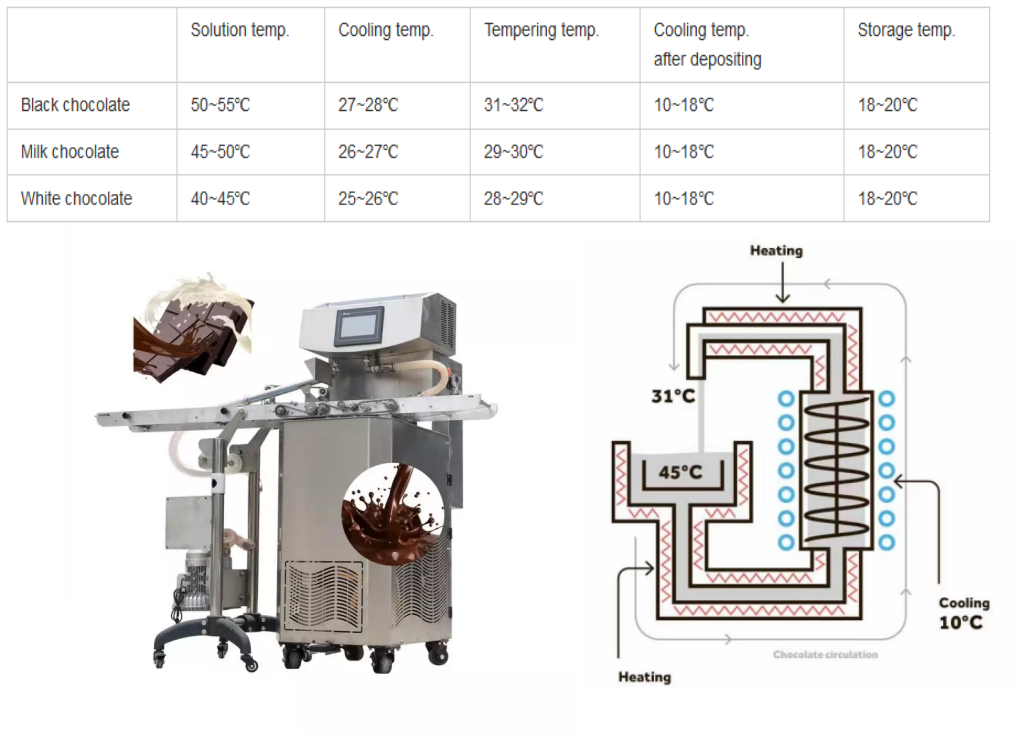

Cocoa butter is polymorphic, zvinoreva kuti, pasi pemamiriro akasiyana ekusimbisa, inoumba marudzi akasiyana emakristasi, anogona kunge akagadzikana kana kusagadzikana.Makristasi akatsiga akanyatso kurongedzerwa uye ane mapoinzi epamusoro ekunyungudika kupfuura makristasi asina kugadzikana.Nokudaro, tinofanira kugadzirisa tembiricha kuti tive nechokwadi chokuti cocoa butter uye cocoa butter-like form the most stable crystal form, uye tozoitonhodza nemazvo kuitira kuti chokoreti ive nekupenya kwakanaka uye irege kutumbuka kwenguva yakareba.Kazhinji nzira yekupisa chokoreti inosanganisira matanho anotevera

1. Sungunusa chokoreti zvachose

2. Kutonhorera kusvika kune crystallization tembiricha poindi

3. Kugadzira crystallization

4. Nyusa makristasi asina kugadzikana

Iyo tembiricha inogona kugadziridzwa nemaoko, asi tembiricha inofanirwa kuve yakarurama.Kusarudza chokoreti tempering muchina unonyatso kudzora tembiricha kusvika kune musiyano wetembiricha isingasviki ± 0.2 inogona kukubatsira zvakanyanya.Kupisa kwemachokoreti akasiyana zvakare hakuenderane zvachose:

Kana muto wechokoreti uchinge wanyatsogadziriswa, unofanirwa kuumbwa pakarepo, wozotonhodzwa kugadzirisa chimiro uye kuchishandura kuva chimiro chakasimba chakasimba.Inogona kudururwa nemaoko kana nemuchina.Kudururirwa mumanyoro mu mold hakuna kunyatsoita sekudira muchina, saka muto wakawandisa unofanirwa kupepetwa.Mushure mekutonhodza, inogona kuve isina kuumbwa kuva chokoreti yakanaka.

Nguva yekutumira: Nov-28-2022