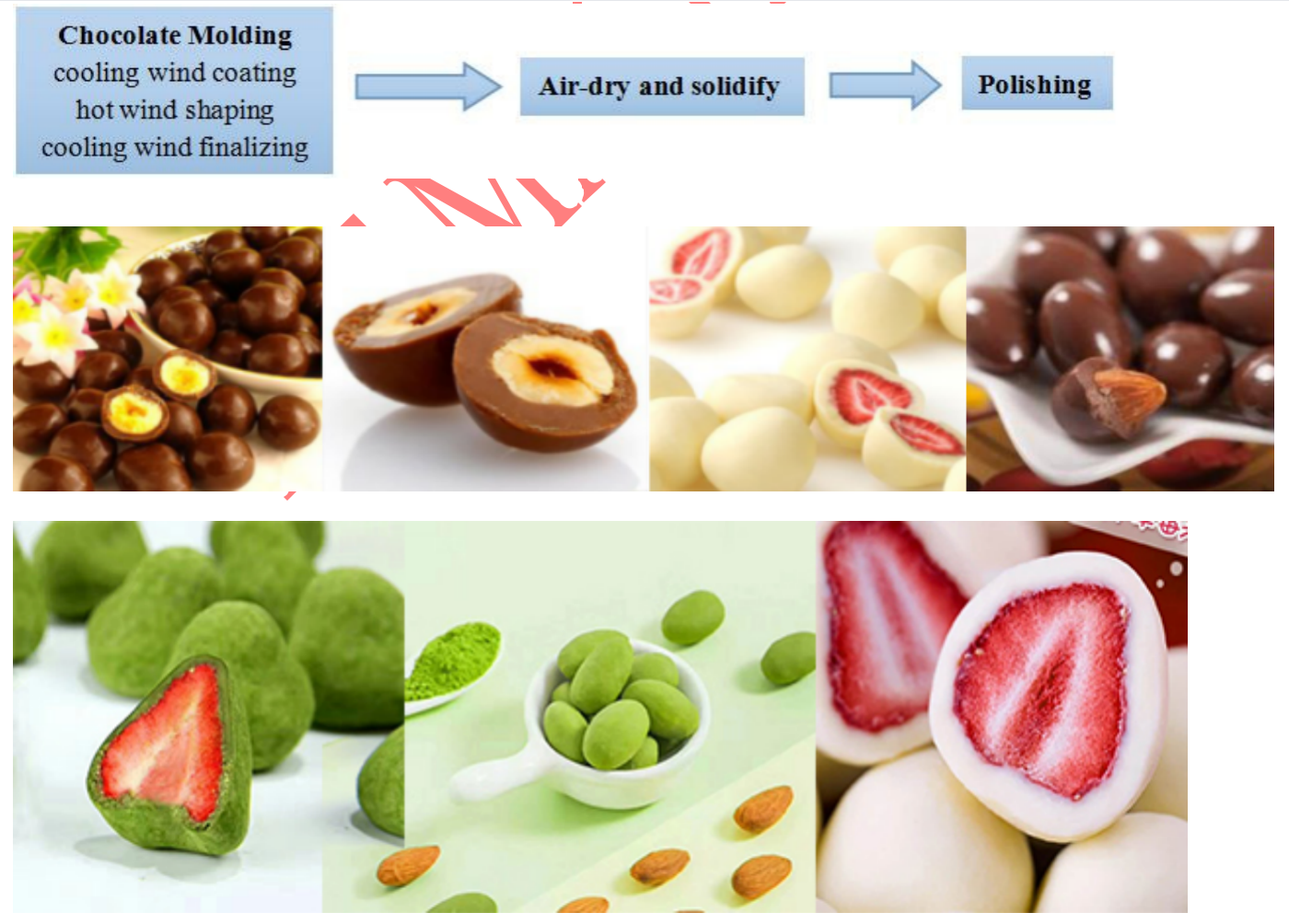

KugadzirwaProcess

Kune chocolate coater ndapota taurasuzy@lstchocolatemachine.com, ndatenda, tine muchina kubva mulabhu kuenda kufekitari, 6kg-1000kg pabatch.

1. Chocolate BeltCoatingMachine

*Chokoreti bhandi rekuvhara & muchina wekuumba

*Chocolate zvinhu zvekudyisa system

* 7P maindasitiri efiriji zvikamu (kutonhora kwemvura uye kutonhora kwemhepo system)

2.Dry Storage (nemutengi)

Imba yakaparadzana inoda kupfuura 15㎡,kuderera kwekushisa uye humidity.Chocolate ichaisa munzvimbo inenge

8-10 maawa ekubvisa humidify uye kusimba.Ichawedzera kupenya uye pasherufu nguva yechokoreti.Vatengi vanorairwa

kuisa chigadzirwa mudiki pallet uye kuisa pane multilayer masherufu.

3.Chocolate polishingMachine

* Chocolate Belt Polishing Machine

* 7P Industrial refrigeration system

4.ForSpecialProduct

1.kana zvigadzirwa zvisina kusimba uye chigadzirwa chakazvitutumadza, Diameter ≥4mm, stuffed material ≤250 litres.Iyo yakanyanya kusimba, iyo ishoma zvinhu.

2.Kune zvigadzirwa zvine kona uye kumucheto, kutenderera chimiro uye kuenderana ukobvu hazvikurudzirwe.

3.Kune chigadzirwa chekunamatira, isa zvinhu zvishoma zvekunamatira.Kana zvinhu zvinonamatira pamwechete uye kuita kuumbwa.

4.Pachokoreti paste, zvinodikanwa kusefa usati wawedzera kuti udzivise block of spray nozzle.

5.Main Features & Advantages

1.Kugadzira otomatiki, chengetedza manpower / yakanyanya kugadzirwa kunyatsoita / yakakura kubuda.

2.Full otomatiki chokoreti kudya, kukoira uye kuumba.

3.Auto weighting uye auto switching yemhepo inopisa nemhepo inotonhora.

4.Programmed production process inoita chigadzirwa

5.Chocolate atomized pfapfaidzo uye kudira anosangana inokosha zvinodiwa zvakasiyana chigadzirwa.

Nguva yekutumira: Oct-18-2021