Newest Fully Fully Otomatiki Chain Inofambisa Zviyo Yakatsiga Chocolate Kugadzira Muchina Automatic Oatmeal Cereal Bar Kugadzira Muchina Wekugadzira Muchina.

●Kusuma Chigadzirwa

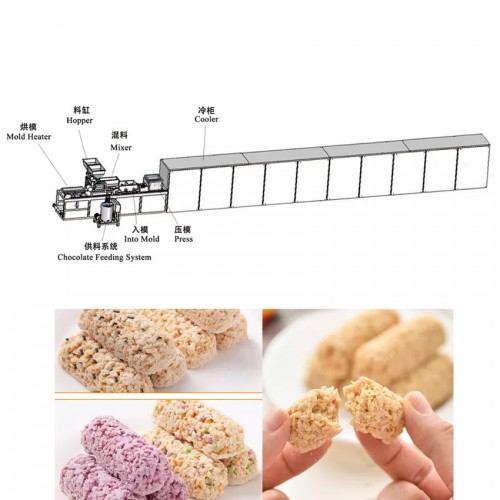

Iyo chokoreti Cereal bar yekugadzira mutsara ndeye multifunctional yekugadzira tambo yekugadzira cereal mabara.Yese mutsara wekugadzira inodzorwa neakabatana touch screen PLC kunze kwematangi ekubata uye hupfu hwekudyisa system, iyo yakagadzikana, yakachengeteka, uye iri nyore kushanda.Mutsara wekugadzira une mutengo wakanaka uye unhu hwakavimbika.Iyo otomatiki Cereal chokoreti yekugadzira mutsara inoumbwa ne mold heater system, chokoreti Cereal yekusanganisa system, mold yekuzadza system, scraping system, flattening system, kutonhora system, demoulding system.Inogona kugadzirwa zvichienderana neyakasiyana zvigadzirwa uye kugona.

LST Machinery, yakavambwa muna 2009, iyo iri muChengdu, inova imwe chiyero uye ine nyanzvi kambani yekugadzira & kutengesa.

5 yepamusoro tekinoroji uye tsvakiridzo nekuvandudza tsvimbo, , 3 akasiyana epamusoro uye matsva matekinoroji achaitwa gore rega rega.Kupfuura makumi matatu ekugadzira vanhu uye timu yakanaka yekutengesa uye mushure me-sevhisi inotsigira.

OEM inotsigira, nyanzvi yakazara mhinduro uye kwenguva refu kubatana.

●Zvinhu

1.PLC kutonga, auto-frequency control

2.man-machine touch interface kuona mazinga emvura uye yakasimba zvinhu.Yakawandisa dziviriro kune alarm kana paine chinhu chisina kumira zvakanaka, uye kuratidza pane yekubata skrini

3.programming kuchengetedza zvigadzirwa kuti uchinje chokoreti ruvara uye zvigadzirwa maminitsi gumi nemashanu.More kugadzikana paunenge uchimhanya nemishonga

4.yakaparadzaniswa kupisa uye kutonga system.Iyo yekudziya sisitimu inochengeta chokoreti mukupisa nguva dzose kana iyo control system yakadzimwa, saka hupenyu hwesevhisi hwekutonga system hurefu.

5.inogona kusanganisa chokoreti, nut butter, muchero, kana zviyo nezvimwe zvidimbu zvekudya;zvingwa zvechigadzirwa zvakasiyana uye zvinogona kugadziriswa

6.yakashongedzerwa ne 2 yakakwirira precision cam rotor pombi kusanganisa zvinhu zvichienderera.Iyo batching system uye iyo yakakwira chaiyo cam rotor pombi inogona kuchengetedza yakagadzikana chikamu chechokoreti panguva yekugadzira.

7.panguva yekugadzirwa, zvinhu zvinosanganiswa zvinogona kuonekwa ne sensor, uye inowedzerwa ne transducer.Iyo yese yekugadzira maitiro inodzorwa ne sensor, uye hapana chikonzero chekumira.

8.yakagadzirwa nesimbi isina tsvina, uye inofananidzwa nemidziyo yakakosha senge SMC isiri-inductive magineti cylinder, inogona kuzadzisa chikafu chehutsanana chinodiwa.

9.yakatorwa neiyo kunze kwenyika tekinoroji, isu tinovandudza michina yedu zvinoenderana neyekutevera sevhisi uye mushumo wekuyedza.Nezvinodiwa nevatengi, isu tinowedzera imwe seti yezvinhu zvinotakura zvinhu uye chokoreti inotakura unit kusiyanisa zvigadzirwa zvedu.

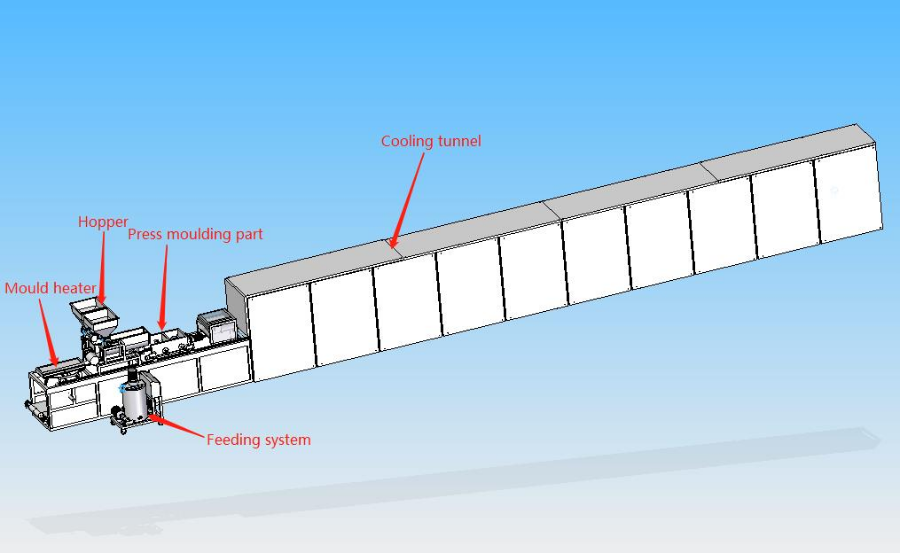

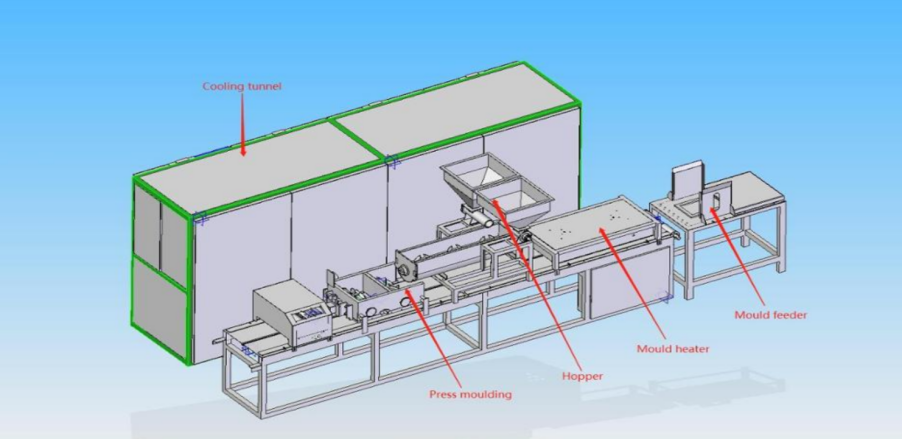

10.mutsetse wese wekugadzira unosanganisira: molds, kusanganisa uye kugadzira unit, inotonhorera unit, yekurongedza unit

11.the corn mold clamping device inogona kuwedzerwa maererano nezvinodiwa nevatengi

●Application

●Parameter

| Molds | 470mm*253mm*30mm |

| Hopper | maviri kana gadzirisa zvimwe |

| Drive Motor | Mafambiro ese anofambiswa ne servo motors |

| PLC | Standard DELTA PLC, Siemens PLC iripo |

| Kubudirira | 10 molds/min |

| Simba | 380V/440V-chimwe chikamu 50/60HZ, kana customized |

●Samples

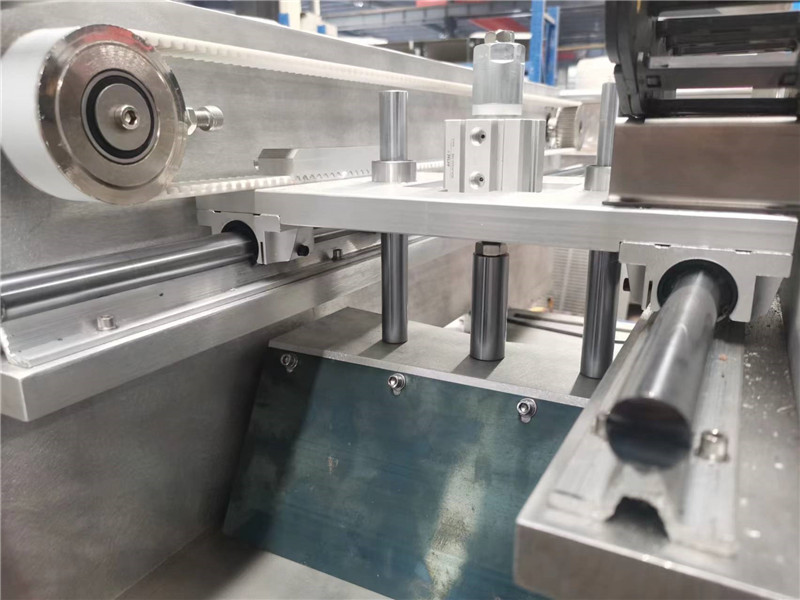

Scraper

Demoulder

Pazasi mold return

By Chain Moving

●Flexible Layout

-Yakazara otomatiki nyowani shanduro

-Yakazara otomatiki nyowani shanduro

●Operation Process

1.Matanho ekushanda akazara otomatiki:kudyisa mold→kupisa mold→kuzadza chokoreti nezviyo→kuisa→kukwesha→kutonhora

→ demoulding (inogona kuwedzera kurongedza muchina)

2.Semi automatics kushanda matanho: feed mold → kupisa mold → kuzadza chokoreti nezviyo → kuisa → kukwenya → manual kusunda kutonhora (kunogona kuwedzera kurongedza muchina)

●Vhidhiyo