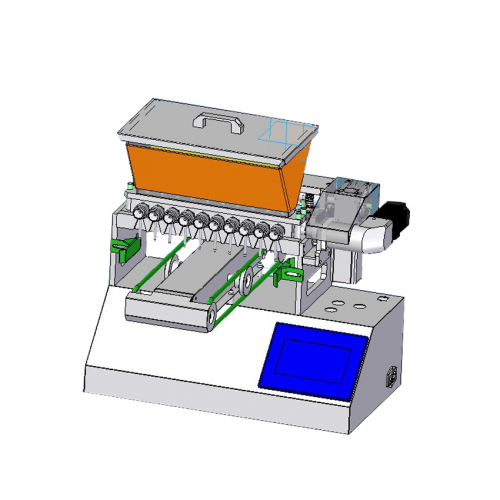

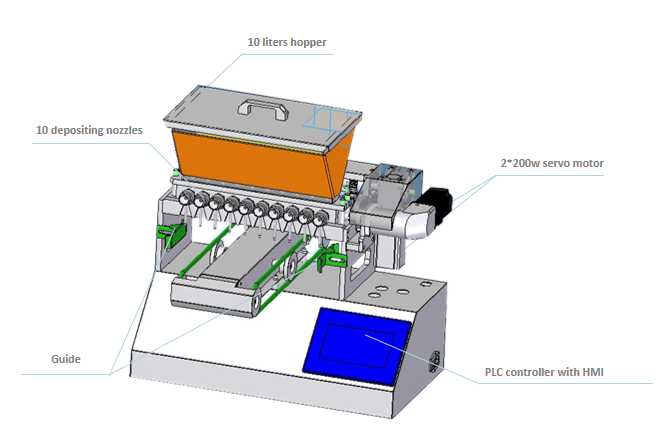

Tafura itsva yepamusoro gumi nozzles chokoreti yekuumba muchina wegummy depositor hard candy chikafu midziyo

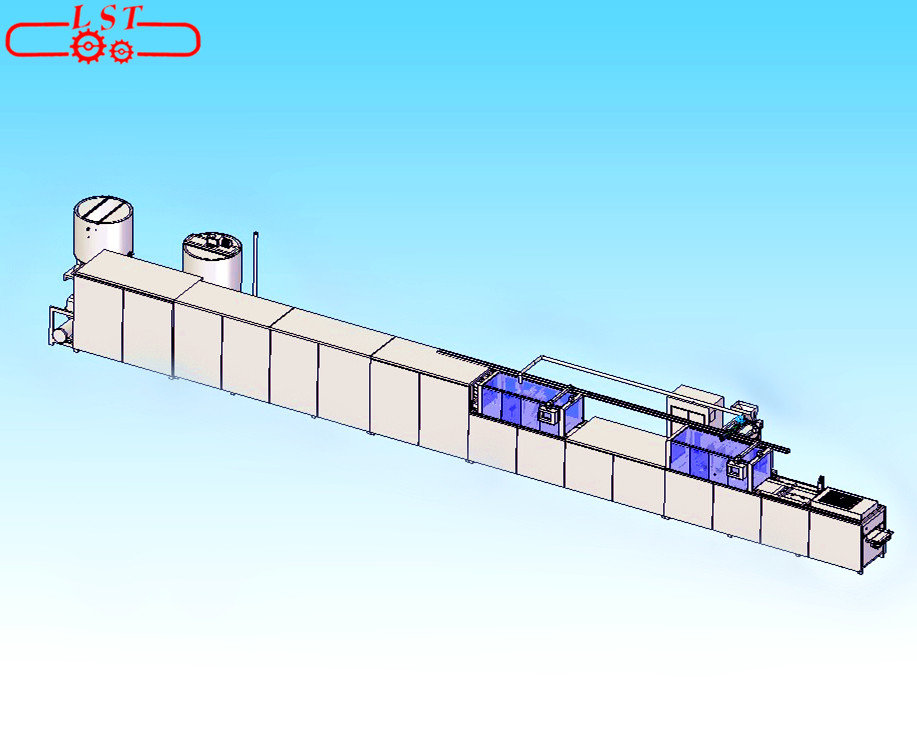

●Kusuma Chigadzirwa

Yakanaka mutengo tafura-yepamusoro confectionery depositor iyo inokodzera machokoreti, caramel, jelly, siwiti yakaoma uye zvihwitsi zvakapfava kuisa.Yakagadzirirwa kuzadza polycarbonate, silicone molds uye chokoreti makoko ane fluid ganache, nougat, couverture kana doro.Deposit mutsara mumwe panguva ine chaiyo dose yezvigadzirwa.

Iyo inodziya nozzles uye inopisa hopper ine inogadziriswa tembiricha yekudzora kuti ubudirire kuisa zvese zvakakwirira uye zvakaderera kupisa zvinongedzo.Cavity mold vhoriyamu inochinjika uye nozzles inogona kuwiriraniswa kuti igare zvakanaka molds dzakasiyana.

LST Machinery, yakavambwa muna 2009, iyo iri muChengdu, inova imwe chiyero uye ine nyanzvi kambani yekugadzira & kutengesa.

5 yepamusoro tekinoroji uye tsvakiridzo nekuvandudza tsvimbo, , 3 akasiyana epamusoro uye matsva matekinoroji achaitwa gore rega rega.Kupfuura makumi matatu ekugadzira vanhu uye timu yakanaka yekutengesa uye mushure me-sevhisi inotsigira.

OEM inotsigira, nyanzvi yakazara mhinduro uye kwenguva refu kubatana.

●Zvinhu

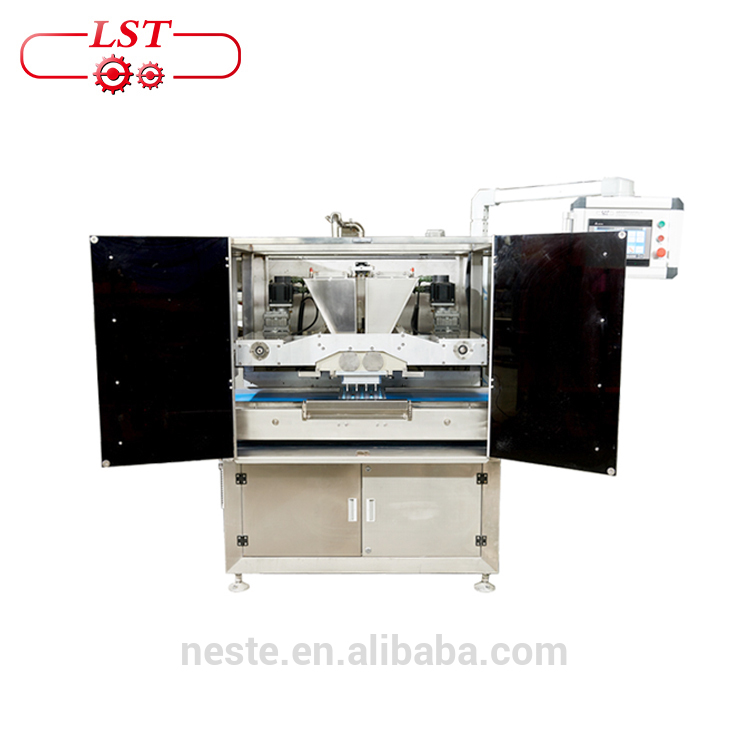

1. Iyi depositor inotora compact uye nzvimbo yekuchengetedza tafura yepamusoro dhizaini

2. 10 inogadziriswa uye inobviswa nozzles

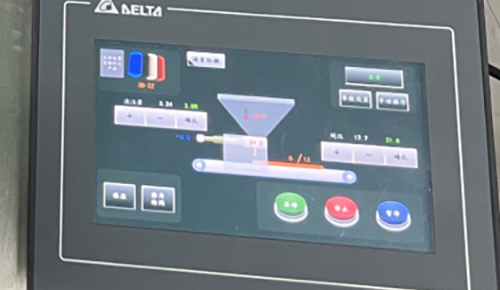

3. 2 Servo motors + PLC inodzorwa kuisa neHMI

4. Kaviri kudziyisa masisitimu ehopper uye nozzles

5. Imwe mold inobata tireyi yesilicone uye mamwe manyoro akapfava

6. Inokodzera chokoreti, caramel, jelly, candy yakaoma, siwiti yakapfava uye mamwe akawanda akafanana manyuchi.

●Application

●Parameter

| Depositing Nguva | 30-60 nguva / min |

| Depositing Weight | 1-7 gramu / pfuti |

| Kubudirira | 2-4 molds/min, 60-100kg/h |

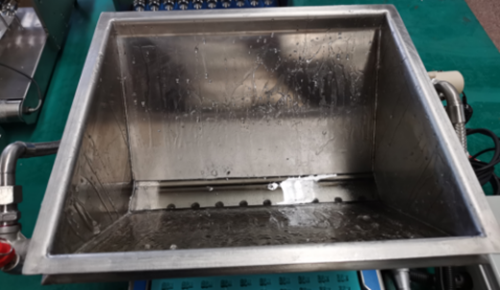

| Hopper Capacity | 10 litres |

| Power Input | 110-240V AC 50-60HZ |

| Total Power | 2.2KW |

| Material | SSS304 |

| Maximum Heat | 130°C |

| Nozzles / Pistons | 10pcs |

| Nozzles spacing | 35mm |

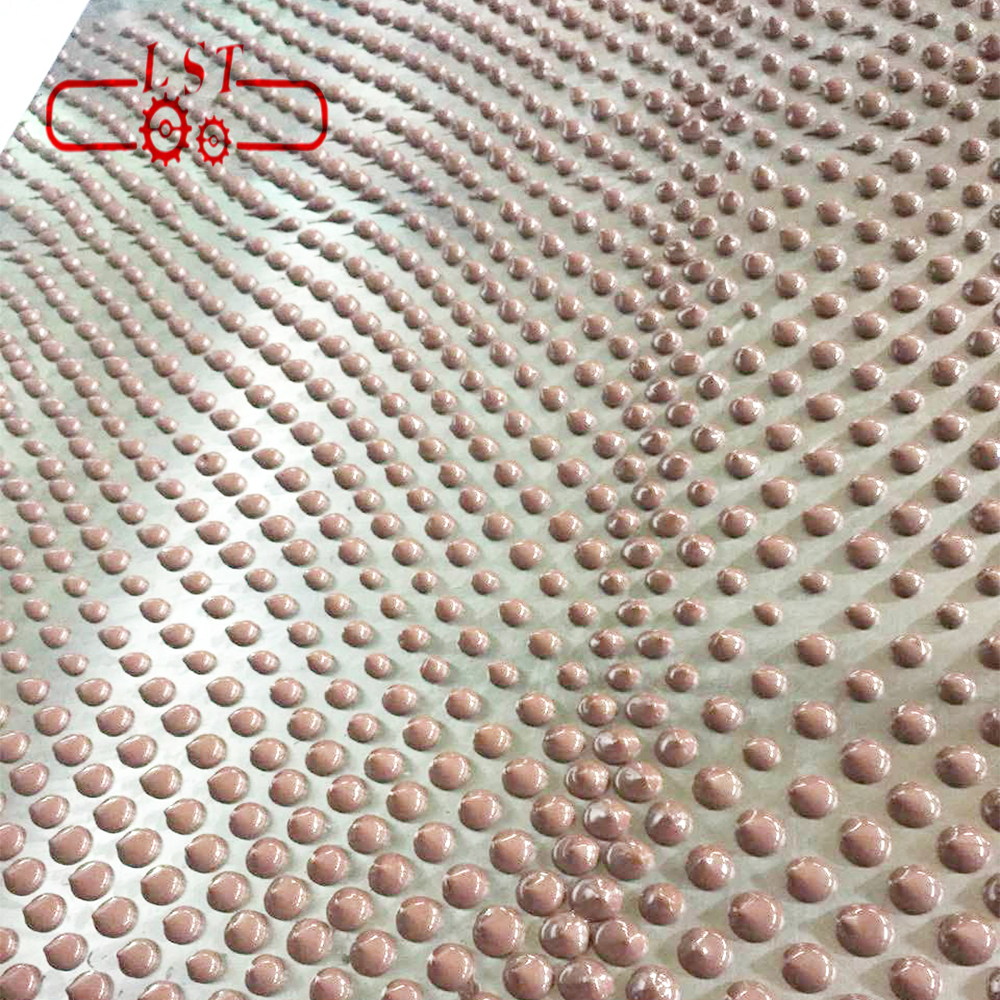

●Samples

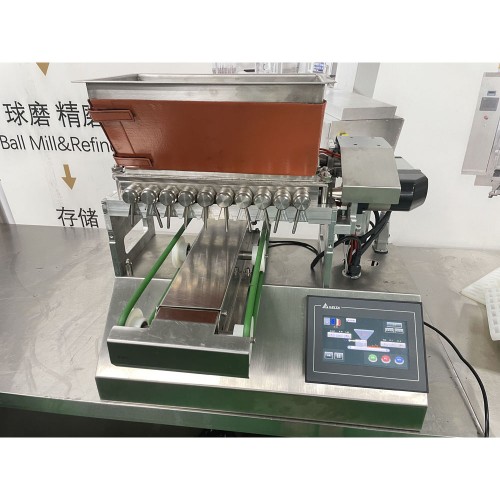

1.PLC Kudzora nekubata sikirini

2. 10 litres hopper

3. Depositing nozzles

4. Pistons

| Aihwa. | Zita | Quantity |

| 1 | O-mhete yekunze dhayamita D12-1.5 | 22 |

| 2 | O-mhete yekunze dhayamita D17-1.5 | 2 |

| 3 | O-mhete yekunze dhayamita D20-1.5 | 10 |

| 4 | O-mhete yekunze dhayamita D25-1.5 | 2 |

| 5 | Proximity switch | 1 |

| 6 | Kupisa chubhu 110V200mm 1KW | 1 |

| 7 | DN15 rubber pad | 2 |

| 8 | PT100 | 1 |

| 9 | US plug | 1 |

| 10 | Mirayiridzo | 1 |

| 11 | Hexagon socket wrench M5,M6 | 2 |

| 12 | Outer hexagon wrench10-12,14-17,19-22,22-24 | 4 |

| 13 | Cross screwdriver | 1 |

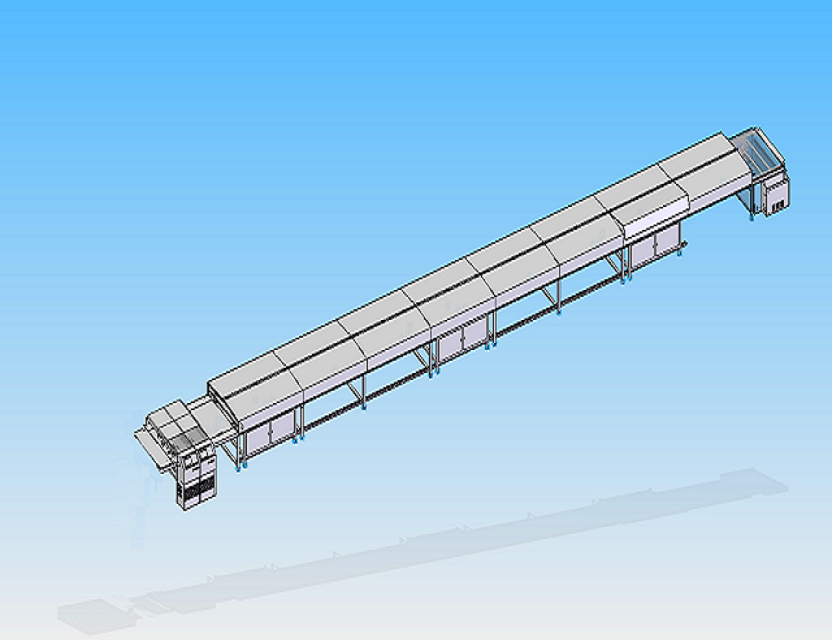

●Flexible Layout

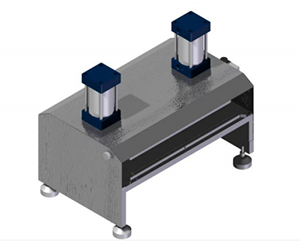

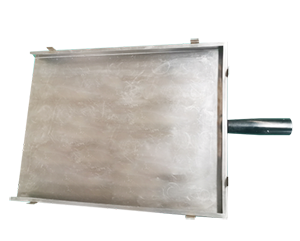

| Manual demoulder | Air press demoulder | Mold tray |

| *Hand-press demoulder yakagadzirwa neSSS304 uye aluminium. * Inowanzo shanda neakapfava silicone molds.*Zvinogona kuve customized maererano akasiyana mold uye candy size *Kushanda kuri nyore uye kuri nyore. | *Air-cylinder Press Demoulder ine 2 silinda yemhepo yakasimba yekutsikirira * Inowanzo shanda neakapfava uye akaoma silicone molds. * Inogona kugadzirwa zvinoenderana neyakasiyana mold uye candy size *Kushanda kuri nyore uye kuri nyore. | * Yakasarudzika saizi yeakasiyana silicone mold. * Yakagadzirwa neSSS304 *Max upamhi ndeye 410mm. * Nekushandisa tireyi kubata silicone molds, maitiro ekuisa anogona kugadzikana uye nyore. |

●Operation Process

1: Batanidza uye chinja

2: Sarudza mutauro

3: Seta Paramita zvinoenderana ne mold uye chengetedza serisiti

4: Tanga kudziyisa kupisa muchina kumusoro

5: Isa mold pabhanhire uye uigadzirise nemanozzles

6: Kupisa bhatani rekutanga gadzirisa huwandu hwekuisa uye nzvimbo

●Vhidhiyo

●Faq

Chii chiri kupisa tembiricha ye depositor?

Maximum tembiricha ndeye 130 degrees.

Ndeipi nzvimbo yepakati yekudira muromo?

35mm, uye imwe nozzle inogona kuchinjika & kubviswa.

Ndezvipi zvigadzirwa zvakakodzerwa nedhipozita iyi?

Chocolate, gummies, jelly, hard candy etc.

Ndeipi molds iyo depositor inoshandisa?

PC molds, silicone molds, uye hupamhi hwekuumbwa haifaniri kudarika 410mm.

Nzira yekuchenesa sei depositor?

Bvisa zvikamu zvinodiwa uye uchenese nemvura inopisa.

Zvakadini nekutumira?

Imwe pasuru yekuunzwa negungwa kana nemhepo, kana mapakeji maviri ekutumira zvakananga (74 * 74 * 47cm 63kg + 69 * 64 * 36cm 38kg).