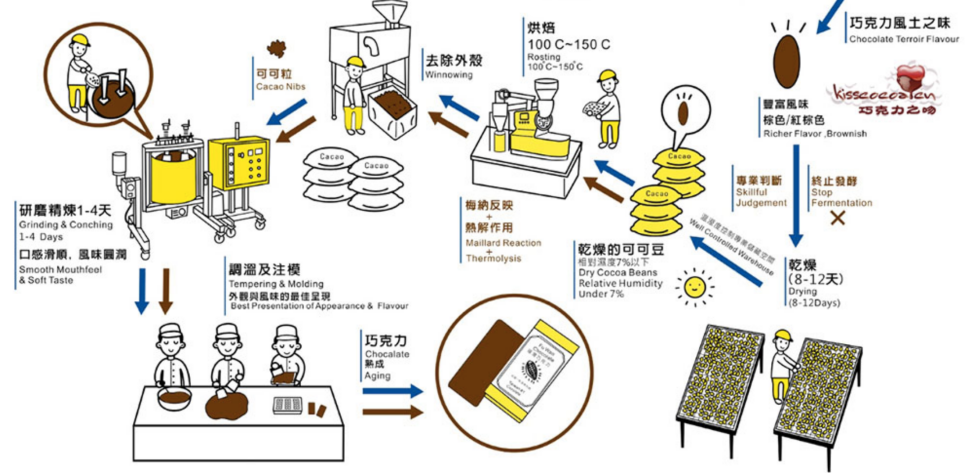

Nyemba za kakao zowuma ndi dzuwa zimatumizidwa ku fakitale, ndikuyambitsa mwalamulo ulendo wake wosintha ... Kuchokera ku nyemba zowawa mpaka chokoleti chokoma, ndondomeko yowonongeka imafunika.Malinga ndi ndondomeko ya processing, zikhoza kugawidwa pafupifupi 3 njira, pulping Pressing, chabwino akupera ndi kuyenga, kusintha kutentha ndi akamaumba.

Tsopano, malo ambiri padziko lapansi amasungabe njira yoyamba yopangira nyemba za koko, koma zopangidwa ndi manja kuchokera ku nyemba za koko kupita ku chokoleti, kukoma kwake kumakhala kowawa.Choncho nkhaniyi makamaka ikukamba zamomwe mungagwiritsire ntchito makina kuti mutsirize ndondomekoyi

1. Kupera ndi Pkupuma

Nyemba za koko amaphwanyidwa ndi kufinyidwa kuti apeze mowa wa cocoa, batala wa koko, ndi ufa wa koko.

Isanayambe kukoka ndi kukanikiza, iyenera kudutsa njira yosankha nyemba, kutsuka, kukazinga, kupeta ndi kuphwanya.Kusankha nyemba, monga momwe dzinalo likusonyezera, ndikuwunika nyemba za koko zosayenerera kapena zowonongeka.Sambani nyemba, muzimutsuka ndi kuziwumitsa.Kenako yambani kuphika, kupeta, kuphwanya, ndi kupera bwino kuti mupeze chakumwa cha koko, ndipo mulu wa mowa wa koko umazirala kuti mutenge mowa wambiri wa koko.Chakumwa cha cocoa amapanikizidwa kudzera mu makina osindikizira kuti atulutse batala wa cocoa.Ufa wa Koka ndi keke ya koko yomwe imatsalira pambuyo pofinyidwa madzi a koko kuti achotse mafuta, kenako nkuphwanyidwa, kusinja, ndi kusefa kuti apeze ufa wofiyira.

1.1 Kuphika - Makina a Cocoa Roaster

Nyemba za koko amawotcha pa kutentha kwakukulu pakati pa 100 ndi 120 ° C.Ntchito yonseyi imatenga mphindi 30 kuwonetsetsa kuti nyemba iliyonse ya koko imatulutsa kukoma kokoma kwa koko ikakazinga.

1.2 Kupeta ndi kuphwanya - Makina a Cocoa Cracking & Winnowing Machine

Pambuyo pakuwotcha, nyemba za kakao zimakhala zakuda, kuyandikira mtundu wakuda wa chokoleti wokha.Nyemba za koko zimazirala msanga, ndipo zipolopolo zopyapyala zikamawotcha zimayenera kuchotsedwa, zomwe zimafuna kuti mafani aziphulitsa zikopa.Nkhokwe, zomwe zimagwiritsidwa ntchito pa nyemba za koko, zimasiyidwa ndikudulidwa kukhala nsonga.Njira imeneyi imatchedwa kupeta ndi kuphwanya, ndipo pali njira zingapo zosiyana, zomwe zimakhala zovuta kwambiri ndikuchotsa khungu kwathunthu popanda kutaya nyemba.Ngati pali khungu louma losakanizidwa ndi chokoleti, limabweretsa kununkhira.

Izi zitha kuchitikanso musanayambe kuwotcha musanawotchedwe.Nyemba zonse ziyenera kuphikidwa pamalo a 400 ° C kwa masekondi 100, kuti nyemba za koko zikhale zosavuta kukhetsa khungu la nyemba pambuyo pa njirayi.Kenaka amaphwanyidwa mu njere zazing'ono kwambiri, zikopa zilizonse za koko zimachotsedwa panthawiyi, zisanawotchedwe.

M'mafakitale ambiri, njirayi imachitika ndi "fan crusher", makina akulu omwe amaphulitsa ziboliboli.Makinawa amadutsa nyemba kudzera m'mitsempha kuti zithyoledwe osati kuphwanyidwa.Panthawiyi, masifa angapo amalekanitsa tizidutswa tating'ono ting'onoting'ono tosiyanasiyana pomwe mafani amawuzira chipolopolo chopyapyalacho kutali ndi tizidutswa ta pulpy.

1.3 Kupera bwino - Colloid Mill&Melanger

Mu fakitale yamakono ya chokoleti, mutha kusankha kugwiritsa ntchito mphero ya colloid kapena mphero yamwala pogaya nyemba zophwanyidwa kukhala slurry.

Mfundo yogwirira ntchito ya mphero ya colloid ndikumeta, kugaya, ndi kusonkhezera kothamanga kwambiri.Kuperako kumachitika pang’onopang’ono pakati pa mano aŵiri, lina likuzungulira mothamanga kwambiri pamene lina limakhala loima.Kuphatikiza pa kugwedezeka kwamphamvu komanso kuthamanga kwamphamvu kwa eddy, zinthu zomwe zili pakati pa mano zimathanso kumetedwa mwamphamvu komanso kuvala.Zinthuzo zidzaphwanyidwa mofanana, omwazika ndi emulsified.

Mphero za miyala zimagwiritsa ntchito zodzigudubuza ziwiri za granite pogaya mosalekeza.Batala wa koko womwe uli mu nyemba za nyemba za koko umatulutsidwanso pang'onopang'ono pambuyo popukuta bwino kwa nthawi yayitali yosayimitsa, kupanga slurry yokhuthala, yomwe imakhazikika kukhala zotupa pambuyo pozizira.

M'malo mwake, zikafika pa siteji yakupera bwino ndikuyenga, sikuli kanthu koma kusinthira kukhala "chosanja chopukutira" chopukutira mosalekeza.

Cocoa butter imagwira ntchito ngati mafuta pamene shuga ndi ufa wa koko zimasinthidwa kukhala tizigawo ting'onoting'ono.M'kamwa mwa munthu mumatha kulawa tinthu tating'onoting'ono toposa 20 microns.Popeza aliyense amakonda kusangalala ndi chokoleti chosalala komanso cholemera kwambiri, tiyenera kuwonetsetsa kuti tinthu tating'onoting'ono ta chokoleti tizikhala tating'ono kuposa kukula uku.Izi zikutanthauza kuti ufa wa kakao uyenera kuchepetsedwa mpaka ma microns 20, omwe ndi sitepe yotsatira yoyeretsa ndi kuyeretsa, kotero iyenera kupitiriza kugaya kwa nthawi yaitali.

Melanger

Colloid Mill

1.4 Makina Otulutsa-Mafuta Osindikizira & Makina Opera Ufa

Mafuta a koko ndi ufa wa cocoa amakhala ndi madzi a cocoa kapena madzi ochuluka omwe amapangidwa pambuyo pa pulping, omwe amafunikira kuchotsedwa mwa kukanikiza.Finyani chakumwa cha koko kuti mulekanitse batala wa cocoa, womwe uli ndi mafuta 100%, ndiyeno perani keke yotsalayo kuti mupange ufa wa koko, wokhala ndi mafuta 10-22%.

Ikani madzi a koko mu makina osindikizira amafuta okha, ndipo adzakwezedwa ndi pisitoni ya silinda yamafuta, ndipo mafutawo amatuluka kuchokera pomwepa, ndikulowa mu mbiya yamafuta kudzera mu mbale yolandirira mafuta kuti musunge mafuta.

Pali magulu angapo a mipeni yosuntha (kapena prisms kapena mitu ya nyundo) mu gudumu lozungulira mkati mwa mphero, ndi mipeni yokhazikika mu giya la mphete.Pakugundana pakati pa mpeni wosuntha ndi mpeni wokhazikika, zinthuzo zimaphwanyidwa.Panthawi imodzimodziyo, chipinda chophwanyidwa chimapanga mpweya, womwe umatulutsa kutentha pamodzi ndi chinthu chomalizidwa kuchokera pazenera.

2. Kuyenga-Chokoleti Conching Machine

Pofunafuna chokoleti choyera chakuda, simukusowa kuwonjezera zipangizo zina, ngakhale shuga wofunikira kwambiri, koma uku ndiko kusankha kwa ochepa.Kuphatikiza pa cocoa mass, batala wa koko ndi ufa wa cocoa, kupanga chokoleti chodziwika kumafunikiranso zinthu monga shuga, mkaka, lecithin, zokometsera ndi zowonjezera.Izi zimafuna kuyengedwa ndi kuyengedwa.Kupera ndi kuyenga kwenikweni ndiko kupitiriza kwa ndondomeko yapitayi.Ngakhale kuti fineness ya zinthu za chokoleti pambuyo pogaya yafika pachofunikira, sichimatenthedwa mokwanira ndipo kukoma kwake sikokwanira.Zida zosiyanasiyana sizinaphatikizidwe mokwanira kukhala kukoma kwapadera.Kukoma kwina kosasangalatsa kukadalipo, kotero kukonzanso kwina kumafunika.

Tekinoloje iyi idapangidwa ndi Rudolph Lindt (woyambitsa Lindt 5 magalamu) kumapeto kwa zaka za zana la 19.Chifukwa chomwe imatchedwa "Conching" ndi chifukwa poyamba inali thanki yozungulira yopangidwa ngati chipolopolo cha conchi.Conch (conche) amatchulidwa kuchokera ku Spanish "concha", kutanthauza chipolopolo.Chokoleti chamadzimadzi chamadzimadzi chimatembenuzidwa mobwerezabwereza ndi chodzigudubuza kwa nthawi yayitali mu thanki yotere, kukankhira ndi kusisita kuti tipeze mafuta okhwima, kusakaniza fungo ndi kukoma kwapadera, njirayi imatchedwa "kugaya ndi kuyenga"

Pamene mukuyenga, zipangizo zosiyanasiyana zothandizira zikhoza kuwonjezeredwa.

3.Kutentha & Moulds-Kutentha Machine & Kuumba

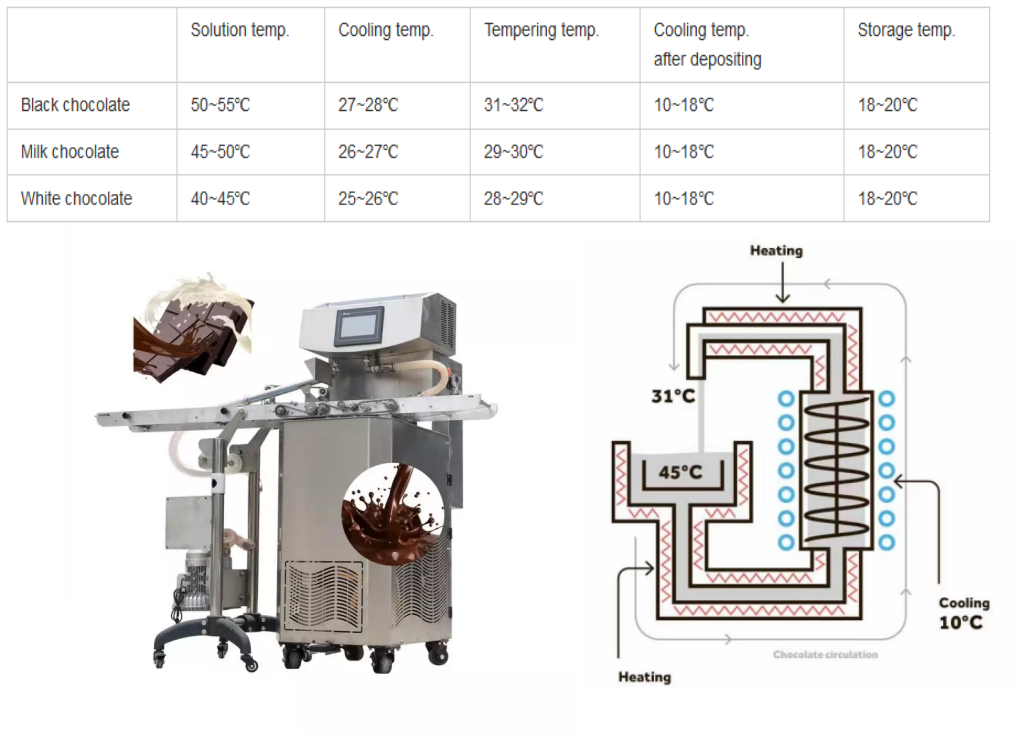

Kutentha ndi gawo lomaliza pakupanga ndipo kumakhudza kwambiri chochita chomaliza cha chokoleti kwa ogula.Kodi mudakhalapo ndi chokoleti chomwe chinali chophwanyika komanso chokhala ndi filimu yoyera yoyera kunja?Mwina kupsya mtima sikunachitidwe bwino kapena chinachake chinali cholakwika ndi zosakaniza.

Kuti tiyankhe funsoli, muyenera kudziwa zinthu zingapo zokhudza batala wa koko.Mafuta a koko amakhala 48% -57% ya kulemera kwa nyemba za cocoa.Ndi chinthu chomwe chimapangitsa chokoleti kuti chisasungunuke m'manja (cholimba kutentha kutentha) chimasungunuka mkamwa ( chimayamba kusungunuka kutentha kwa thupi).Kuyika chidutswa cha chokoleti pa lilime lanu ndikuyimva kuti ikusungunuka pang'onopang'ono mkamwa mwanu ndi zina mwazinthu zokopa kwambiri za chokoleti, ndipo zonsezi ndi chifukwa cha batala wa koko.

Cocoa batala ndi polymorphic, zomwe zikutanthauza kuti, pansi pa mikhalidwe yolimba yosiyana, imapanga mitundu yosiyanasiyana ya makristasi, omwe angakhale okhazikika kapena osakhazikika.Makhiristo okhazikika amakhala odzaza kwambiri ndipo amakhala ndi malo osungunuka kwambiri kuposa makhiristo osakhazikika.Choncho, tiyenera kusintha kutentha kuonetsetsa kuti koko batala ndi koko batala ngati mawonekedwe khola kristalo mawonekedwe, ndiyeno kuziziritsa izo molondola kuti chokoleti kukhala ndi luster wabwino ndipo si pachimake kwa nthawi yaitali.Kawirikawiri njira yowotchera chokoleti imaphatikizapo zotsatirazi

1. Sungunulani chokoleti kwathunthu

2. Kuzizira mpaka kutentha kwa crystallization

3. Kupanga crystallization

4. Sungunulani makhiristo osakhazikika

Kutentha kumatha kusinthidwa pamanja, koma kutentha kuyenera kukhala kolondola.Kusankha makina otenthetsera chokoleti omwe amawongolera bwino kutentha mpaka kusiyana kwa kutentha kosakwana ± 0.2 kungakuthandizeni bwino kwambiri.Kutentha kwa chokoleti zosiyanasiyana kumakhalanso kosagwirizana kwathunthu:

Msuzi wa chokoleti ukatenthedwa bwino, uyenera kupangidwa nthawi yomweyo, kenako utakhazikika kuti ukonze dongosolo ndikusintha kuti ukhale wolimba.Ikhoza kuthiridwa ndi manja kapena makina.Kuthira pamanja mu nkhungu sikuli kofanana ndi kutsanulira kwa makina, kotero msuzi wowonjezera uyenera kuchotsedwa.Pambuyo kuziziritsa, ikhoza kusinthidwa kukhala chokoleti chokongola.

Nthawi yotumiza: Nov-28-2022