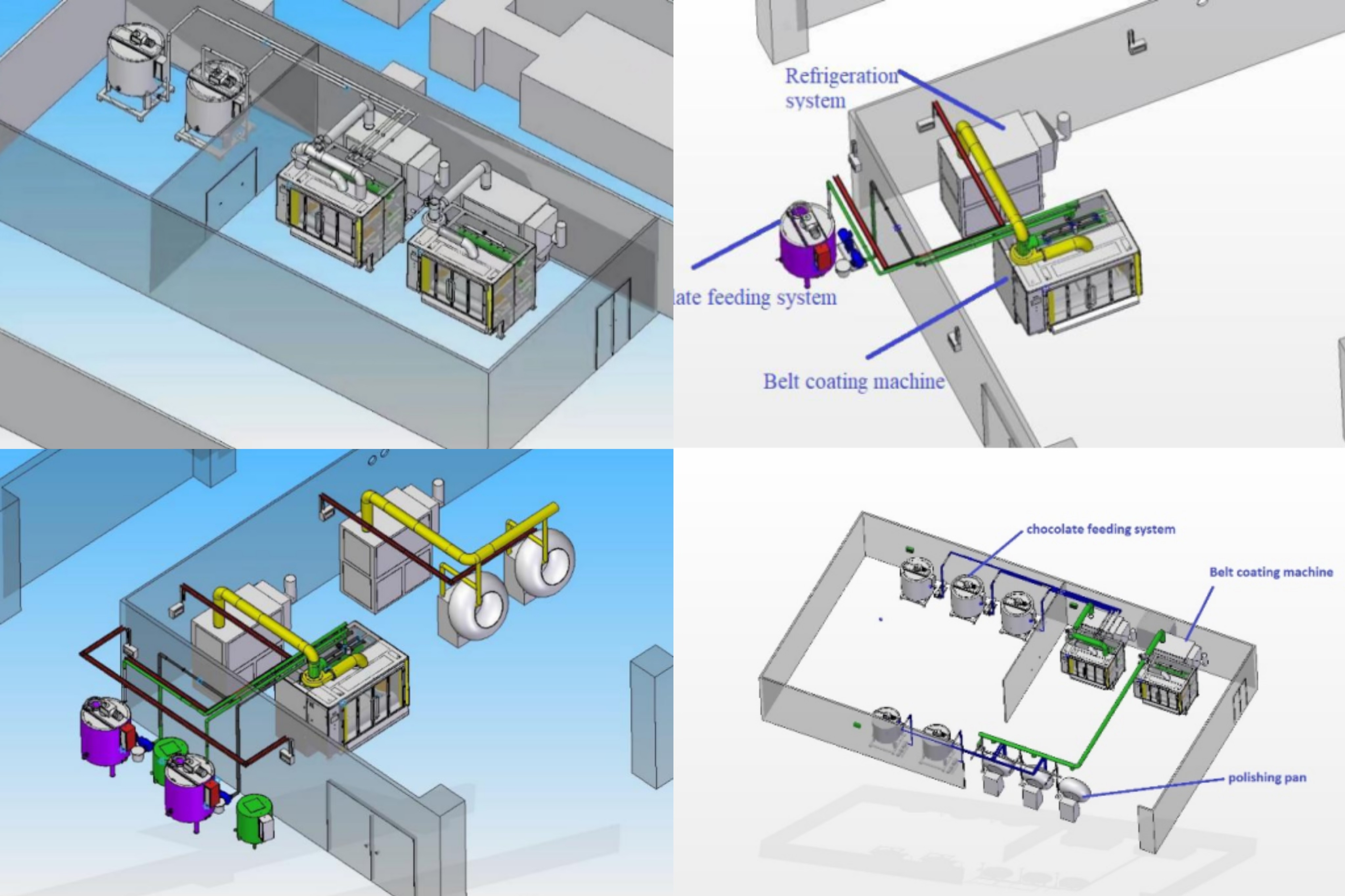

Nut Chocolate Belt Coating System With 500L Feeding System

●Product Introduction

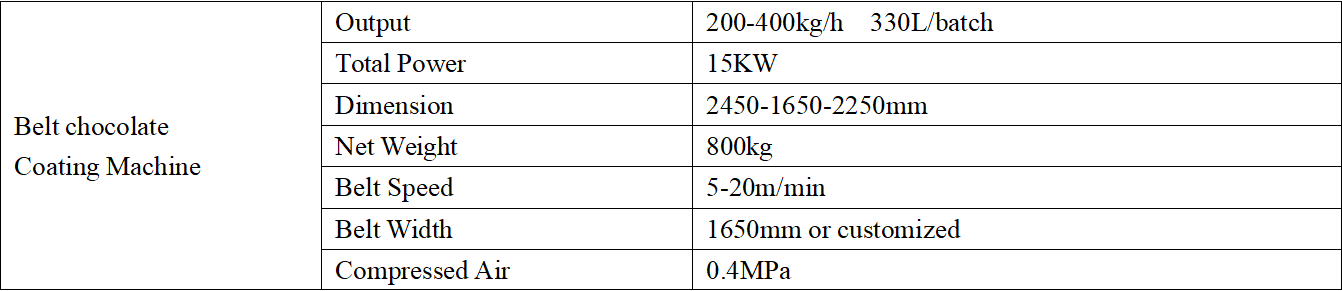

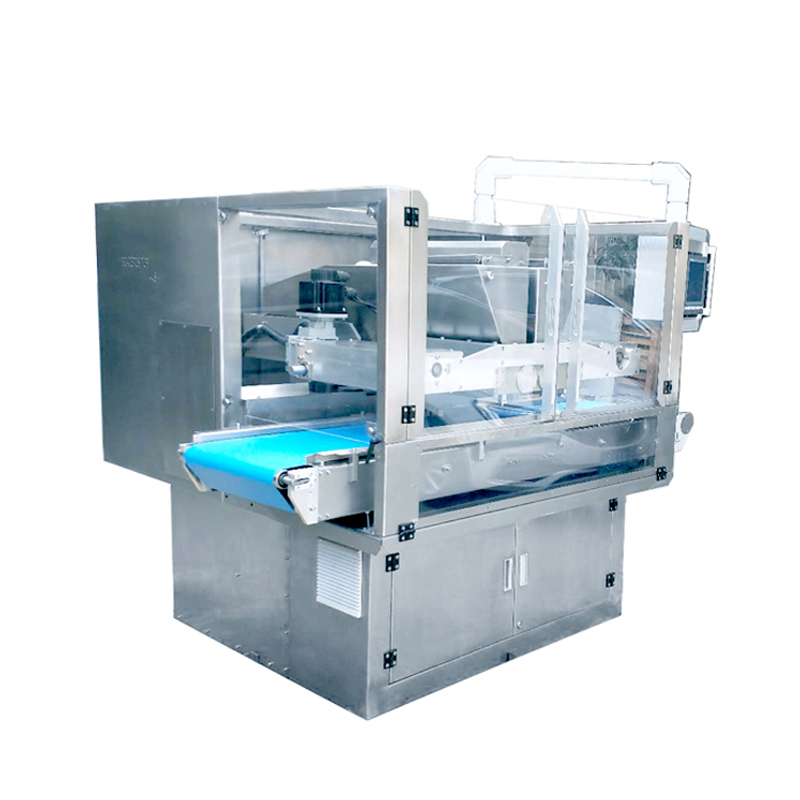

Chocolate Coating Machine unit

A. Adopts PLC system,can save all kinds of product’s formula and auto control the whole production process.

B. Spray capacity and spray time can be set accordingly for different products.

C. Edible grade PV belt. The filling material will rotate in high speed on the belt.

D. Electrical weigh will automatically weigh the materials according to product formula.

E. Full automatic programmable control.

F. Automatic Feeding System main consists of Chocolate Storage Tank,Chocolate Slurry Pump and Stainless Steel Interlayer Insulating Pipe.

G. Machine adopts DELTA Control system and Siemens electronic components.

H. 10 inch Touch Screen

I. Language Available: English & Russian

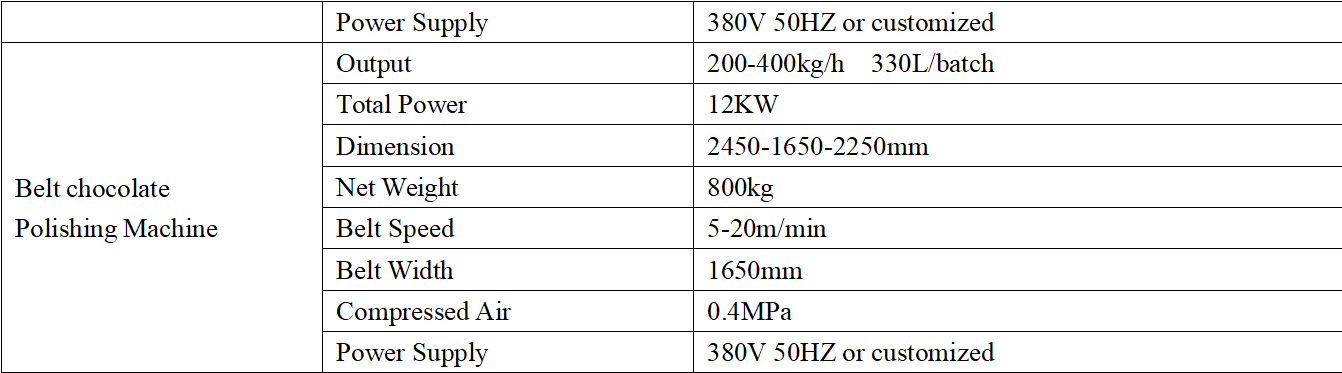

Chocolate Polishing machine unit

1.The whole machine adopts PLC program control, and the production process is programmed controlled.

2.The conveyor belt is made by PV food grade material. The polishing products rotate with high-speed with the action of chain plate conveyor belt, and by the program control, polishing oil shall spray automatically and evenly on product surface.

3.According to different requests of production techniques, the equipment can be set for different polishing time, times for polishing oil, volume of polishing oil, as well as different speed for chain board at different stages.

4.There is switch for shifting between cold and hot air in the polishing process. The equipment can meet the technological requirements of cooling time for different products.

5.DELTA Control system,10 inch Touch Screen,Siemens electronic components.Language Available: English & Russian.

●Video