This is a very dry article, and it will benefit you a lot after reading it!

Know more chocolate tempering machine, please contact:suzy@lstchocolatemachine.com/ whatsapp:+8615528001618

Why does chocolate need to be tempered?

Chocolate is made from the seeds of the cacao tree. The cocoa pods are fermented, dried, and roasted to obtain cocoa beans, which contain about 51% to 55% fat, which is called “cocoa butter”.

Cocoa butter is a very magical oil. It is composed of a variety of fatty acids, and its composition ratio is very different from other fats. As shown in the figure below, its solid fat index curve is compared with butter, butter and other fats. It is very steep. It starts to soften at 28 degrees Celsius, and the solid content quickly turns into liquid at 33 degrees Celsius.

Why can chocolate remain hard and solid at room temperature, and it is crunchy when bitten, but it melts in the mouth?

Why can chocolate remain hard and solid at room temperature, and it is crunchy when bitten, but it melts in the mouth?

It is the narrow melting point of cocoa butter that is close to human body temperature that makes the taste of chocolate.

Seamless connection of temperature! How can there be a feeling that the existence of chocolate is to satisfy human desire for food?

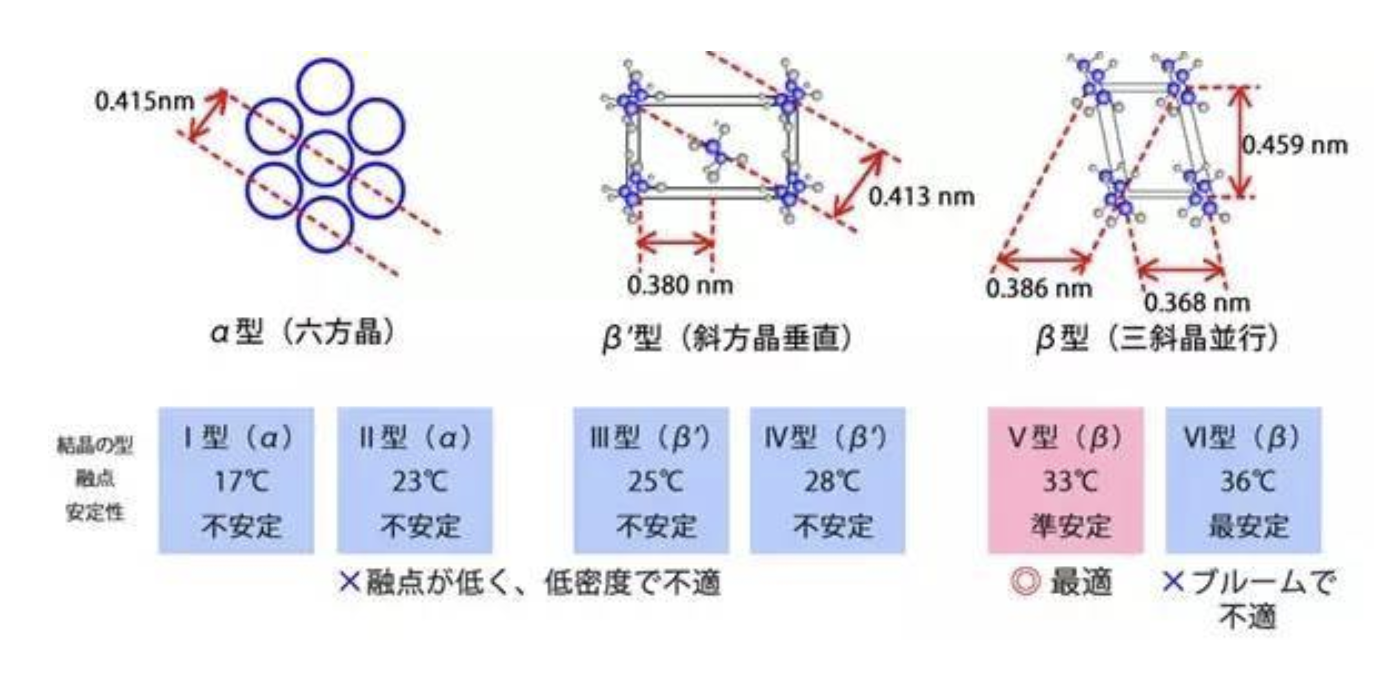

Specifically, cocoa butter has a variety of different solid butter crystalline forms.

There are generally 4 common types, namely γ, α, β’, β. Under different temperature conditions, the crystal form conversion is shown in the following figure:

The melting point of γ-type crystal is 16~18℃, which is very unstable, and it will transform into α-type in about 3 seconds. Ignorable.

The structures of the other three crystals are shown in the figure below:

α-type crystals (type I and II): melting point 17~23℃, it will transform into β’-type crystal in one hour at room temperature. The texture is soft, fragile and easy to melt.

α-type crystals (type I and II): melting point 17~23℃, it will transform into β’-type crystal in one hour at room temperature. The texture is soft, fragile and easy to melt.

β’-type crystals (type III and IV): melting point 25~28℃, it will transform into β-type crystal in the next month at room temperature. The texture is hard, not brittle, and easy to melt.

The most stable β-type crystals (V-type and VI-type) have a melting point of 33~36°C, with a hard and brittle texture, and a melting temperature close to human body temperature. However, the most stable type VI crystal particles with the highest melting point are coarse and taste bad, and will produce fat bloom on the surface (this is why a layer of “hoarfrost” will form on the surface of chocolate after a long period of time), so it is more Metastable V-shaped crystals that are stable and have a glossy appearance have become the most ideal grease structure.

The purpose of temperature adjustment is to melt the chocolate and adjust the temperature to obtain the most ideal homogeneous polymorphism, giving the chocolate a crisp, silky taste and a beautiful shiny appearance.

The purpose of temperature adjustment is to melt the chocolate and adjust the temperature to obtain the most ideal homogeneous polymorphism, giving the chocolate a crisp, silky taste and a beautiful shiny appearance.

Going back to the four temperatures mentioned above, why is the second cooling point of bittersweet chocolate until 28°C?

It is to avoid the formation of other undesirable crystals in cocoa butter, which will affect the quality of the finished chocolate.

In addition, the cocoa paste and sugar in chocolate will also have an impact on the crystallization process, but relatively speaking, it is not as great as the temperature adjustment, so I will not mention it here for the time being.

So, how to speed up cooling to produce V-shaped crystals?

How should the temperature be adjusted?

Take the most popular milk chocolate as an example:

STEP1: Generally, the method of heating in water is used to melt the chocolate. As shown in the figure below, it is heated to 40°C in water. During this time, it needs to be stirred continuously, and be careful not to let water vapor enter the chocolate.

STEP2: There are many ways to cool down, such as water cooling, tablage, seeding, etc.

These methods are to quickly cool the chocolate to avoid the formation of VI crystals with coarse particles and poor taste.

Take the most commonly used and most handsome marble table cooling method as an example. Pour two-thirds of the evenly melted chocolate on the marble table.

Use a spatula to repeatedly scrape and cut until the chocolate becomes thick and starts to stick to the spatula and cannot flow down. The picture below is an example.

At this time, the temperature is about 25°C, and fine oil crystals have formed. It is necessary to scrape all the chocolate on the table back into the original pot immediately, and the temperature should not continue to decrease to produce β’-type crystals or even α-type crystals.

At this time, the temperature is about 25°C, and fine oil crystals have formed. It is necessary to scrape all the chocolate on the table back into the original pot immediately, and the temperature should not continue to decrease to produce β’-type crystals or even α-type crystals.

If the temperature is too low, the temperature must be adjusted again from the first step.

STEP3: Rewarming. Scrape all the chocolate on the table back into the original pot and mix it with the uncooled chocolate. The temperature at this time is about 30°C. If the chocolate is too viscous below 30°C for the next step, it can be heated slightly to 30°C in water.

This step must be careful, if the temperature is too high, the oil crystals will melt again, and the temperature must be adjusted again from the first step.

Next, the chocolate that has been tempered can be used to continue injection molding, dipping, and shaping operations.

But still need to pay attention, it is best to use heat preservation equipment to control the temperature, once the temperature is too cold, the chocolate has to be set again.

Therefore, chocolate is a very delicate thing. It is very sensitive to temperature and humidity. If there is any carelessness in the temperature adjustment process, it has to be completely re-started, which is very troublesome.

Post time: Jul-23-2021