01

Why should chocolate be tempered

First of all, before proceeding with all chocolate application operations, one thing we have to figure out is:

Why does chocolate need to be tempered?

The core ingredient of chocolate is cocoa butter. In the final analysis, chocolate tempering is to temper the cocoa butter.

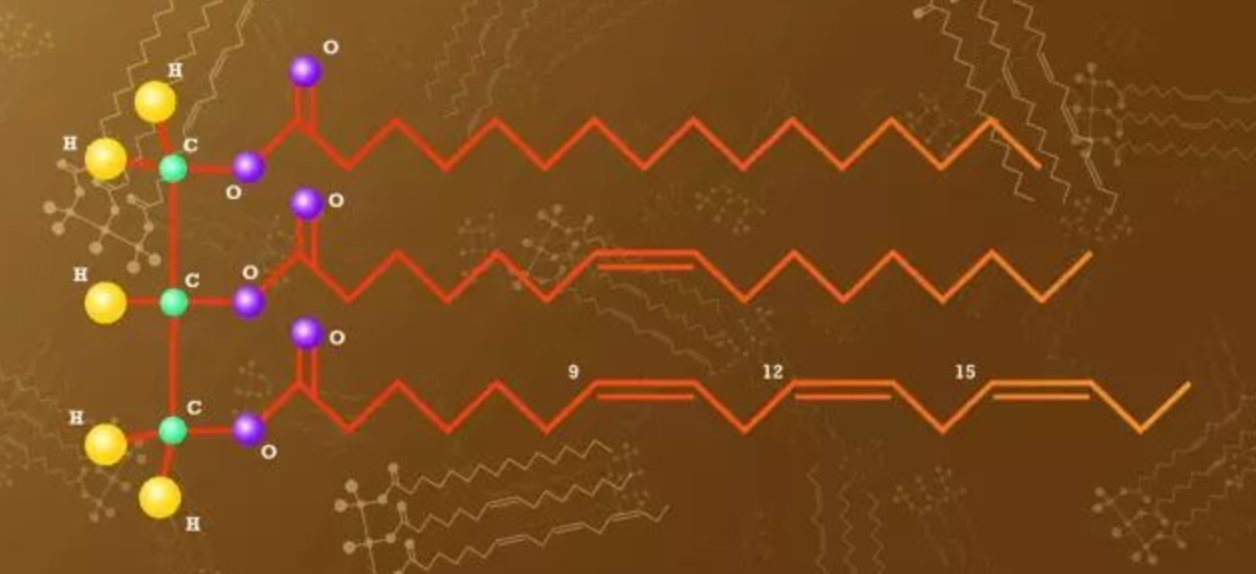

Cocoa butter is a very magical oil. It itself is composed of a variety of fatty acids, and its composition ratio is very different from other fats.

The solid fat index curve of cocoa butter is very steep, starting to soften at 28°C, and at 33°C, the solid content quickly turns into liquid.

This narrow range of melting point but close to the characteristics of human body temperature creates a unique sensory experience in which chocolate can maintain a hard solid form at room temperature, crunch when bitten, but melt instantly once it is entered.

Cocoa butter has many different crystalline forms of solid butter, and there are generally 4 common ones.

These crystal forms will undergo crystalline form conversion under different temperature conditions, and different crystal forms and combination ratios will produce different chocolate tastes and forms.

Therefore, the purpose of our temperature adjustment is to obtain the most ideal homogeneous polymorphism by adjusting the temperature, so that the taste of the chocolate is better and the appearance is better.

02

Common chocolate tempering methods

Next, what we need to know is what are the methods for tempering chocolate?

Chocolate tempering methods can be roughly divided into four types: seed method, microwave oven method, marble tempering method, and water cooling method; no matter which method is selected, the three elements that affect chocolate tempering are the same: temperature, time and stirring. action.

Among the four tempering methods, the most commonly used is the marble tempering method. Basically, in many hotels, including international professional chocolate competitions, the most common tempering method is also this one.

Now let’s take milk chocolate as an example, let’s take a look at the specific steps of the marble tempering method.

Step1- heating up

Melt the chocolate, usually by heating to 40℃ in water (a microwave oven can also be used, and it needs to be operated for several short periods to prevent the chocolate from scorching when the temperature is too high). During the melting, it needs to be stirred continuously, and be careful not to let water vapor enter the chocolate. .

Step2- Cool down

Take out two-thirds of the evenly melted chocolate and pour it on the marble table. Use a spatula to cut repeatedly and quickly. Cool down until the chocolate becomes thick and sticks to the spatula and cannot flow down.

The temperature at this time is about 25°C, and the chocolate has formed fine oil crystals. At this time, you need to immediately scrape the chocolate on the marble countertop back into the remaining 1/3 of the chocolate to prevent the temperature from continuing to drop and produce bad crystals (if If the temperature is too low, the temperature must be re-adjusted from the first step).

Step3- heating up

Scrape all the chocolate on the marble table back into the remaining 1/3 of the chocolate to fully mix it with the uncooled chocolate. The temperature at this time is about 30°C (that is, the operating temperature, which can be used for filling molds, back covers, and making decorations. Wait).

If the temperature of the chocolate is lower than 30°C, it will be too viscous to proceed with the next step. At this time, it can be heated slightly to 30°C in water (this step must be careful, if the temperature is too high, the oil crystals will melt again , Then you have to re-adjust the temperature from the first step).

If you follow the above steps to complete the operation correctly, you can use the chocolate that has been tempered to continue the subsequent operations such as injection molding, dipping, and shaping.

But it should be noted that it is best to use heat preservation equipment to control the temperature (such as a chocolate heat preservation pot). Once the temperature is too cold and the chocolate solidifies, all the steps have to be repeated.

Tempering temperature curve of different chocolates

What we also need to know is that as the milk fat content in the chocolate ingredients increases by 5%, the melting point of the chocolate will decrease by 1°C.

Therefore, the tempering curve of different brands and different percentages of chocolate is different. It is best to look at the packaging before using.

https://youtu.be/YeVEUYBKrbw

inquiry chocolate tempering machine please contact:

email:suzy@lstchocolatemachine.com

whatsapp:+8615528001618

www.lstchocolatemachine.com

Post time: May-06-2021