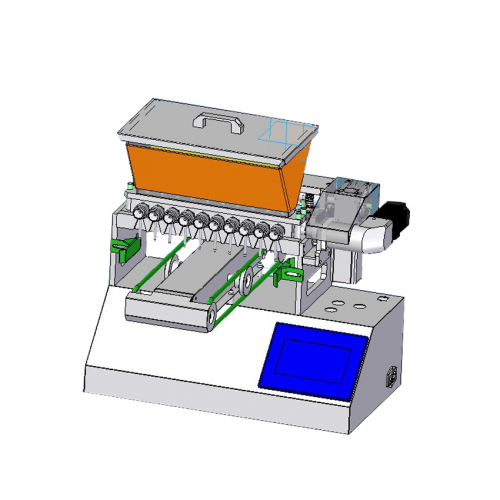

New table top 10 nozzles chocolate moulding machine for gummy depositor hard candy food equipment

●Product Introduction

Nicely priced table-top confectionery depositor which is suitable for chocolates, caramel, jelly, hard candy and soft candy depositing. Designed for filling polycarbonate, silicone molds and chocolate shells with fluid ganache, nougat, couverture or liquor. Deposit one row at a time with a precise dose of ingredients.

The heated nozzles and heated hopper with adjustable temperature control to successfully deposit both high and low heat ingredients. Cavity mould volume is adjustable and nozzles can be aligned to best accommodate different molds.

LST Machinery, founded in 2009,which is located in Chengdu ,which is one standard and professional company for manufacturing & trading .We are highly successful in chocolate food making machine and packing machine etc.

5 top technology and research and development staffs , ,3 different high and new technologies will be carried out each year.More than 30 manufacturing persons and good sales team and after-service supports.

OEM supporting ,professional comprehensive solutions and long-term cooperation.

●Features

1. This depositor adopts a compact and space saving table top design

2. 10 adjustable and removable nozzles

3. 2 Servo motors+PLC controlled depositing with HMI

4. Double heating systems for hopper and nozzles

5. One mold holding tray for silicone and other soft molds

6. Suitable for chocolate, caramel, jelly, hard candy, soft candy and many more similar syrup

●Application

●Parameter

|

Depositing Times |

30-60 times/min |

|

Depositing Weight |

1-7grams/shot |

|

Productivity |

2-4molds/min, 60-100kg/h |

|

Hopper Capacity |

10 Liters |

|

Power Input |

110-240V AC 50-60HZ |

|

Total Power |

2.2KW |

|

Material |

SSS304 |

|

Maximum Heat |

130°C |

|

Nozzles/Pistons |

10pcs |

|

Nozzles spacing |

35mm |

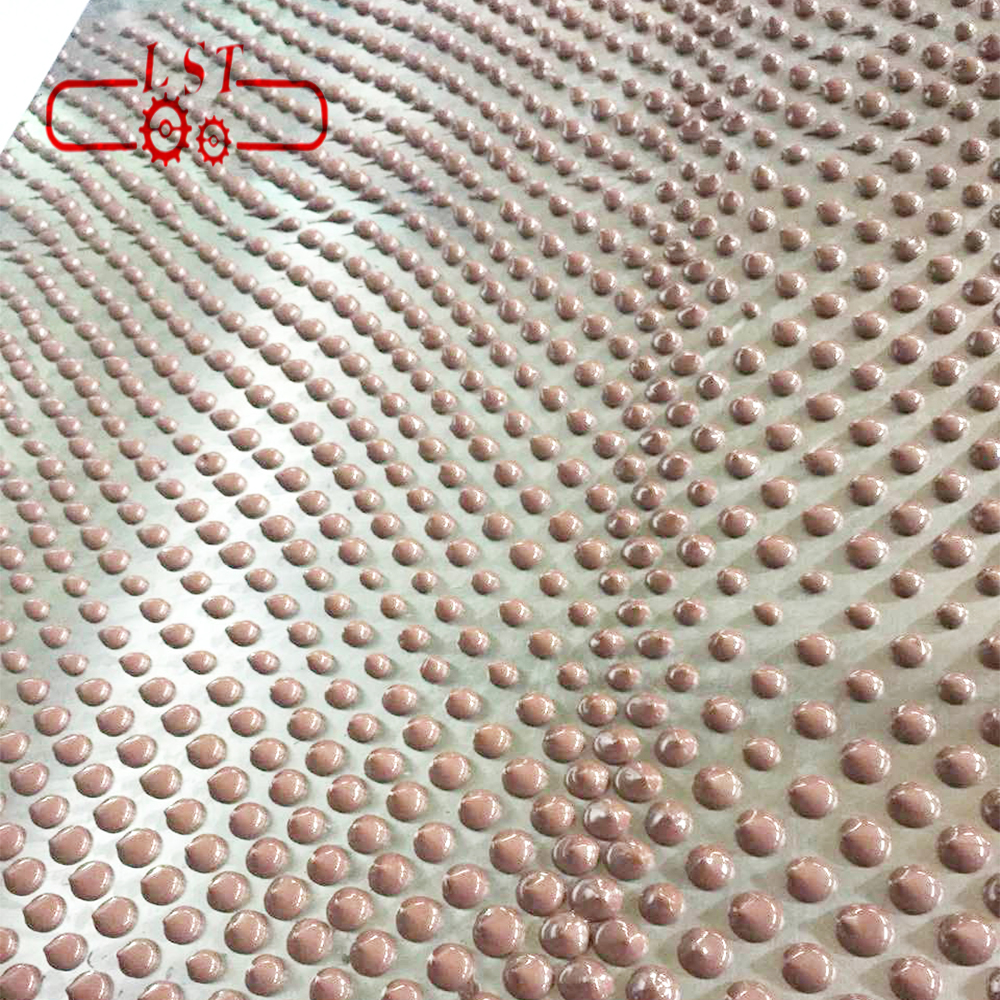

●Samples

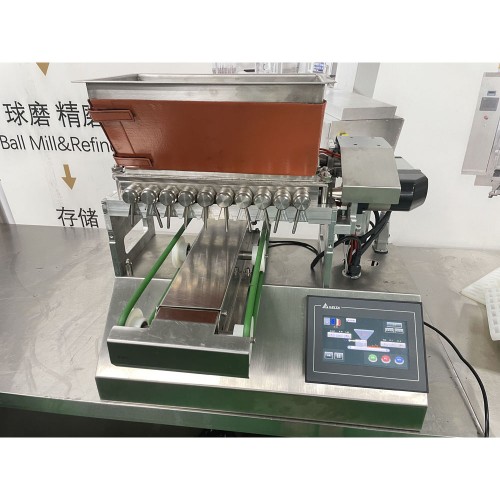

1.PLC Control with touch screen

2. 10 Liters hopper

3. Depositing nozzles

4. Pistons

|

No. |

Name |

Quantity |

|

1 |

O-ring outer diameter D12-1.5 |

22 |

|

2 |

O-ring outer diameter D17-1.5 |

2 |

|

3 |

O-ring outer diameter D20-1.5 |

10 |

|

4 |

O-ring outer diameter D25-1.5 |

2 |

|

5 |

Proximity switch |

1 |

|

6 |

Heating tube 110V200mm 1KW |

1 |

|

7 |

DN15 rubber pad |

2 |

|

8 |

PT100 |

1 |

|

9 |

US plug |

1 |

|

10 |

Instructions |

1 |

|

11 |

Hexagon socket wrench M5,M6 |

2 |

|

12 |

Outer hexagon wrench10-12,14-17,19-22,22-24 |

4 |

|

13 |

Cross screwdriver |

1 |

●Flexible Layout

|

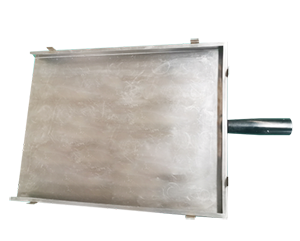

Manual demoulder |

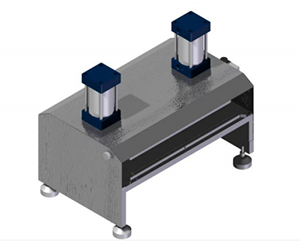

Air press demoulder |

Mold tray |

| *Hand-press demoulder is made of SSS304 and aluminium.

*It usually works with soft silicone moulds. *It can be customized according to different mould and candy size *The operation is simple and convenient. |

*Air-cylinder Press Demoulder is equiped with 2

strong air cylinder for pressing *It usually works with soft and hard silicone moulds. *It can be customized according to different mould and candy size *The operation is simple and convenient. |

*Customized size for different silicone mould.

*Made of SSS304 *Max width is 410mm. *By using a tray to hold silicone molds, the depositing process can be more stable and convenient. |

●Operation Process

1: Plug in and switch on

2: Select language

3: Set Parameters according to the mold and save it as a receipe

4: Start heating to heat the machine up

5: Place the mold on the belt and align it with the nozzles

6: Hot the start button adjust the depositing amount and spacing

●Video

●Faq

What is the heating temperature of the depositor?

Maximum temperature is 130 degrees.

What is the spacing distance of pouring nozzle?

35mm, and each nozzle can be adjustable&removable.

What products are this depositor suitable for?

Chocolate, gummies, jelly, hard candy etc.

Whats molds does this depositor use?

PC molds, silicone molds, and the width of mold should not exceed 410mm.

How to clean the depositor?

Remove necessary parts and clean by hot water.

How about shipping?

One package for deliver by sea or air, or two packages for express delivery (74*74*47cm 63kg + 69*64*36cm 38kg).