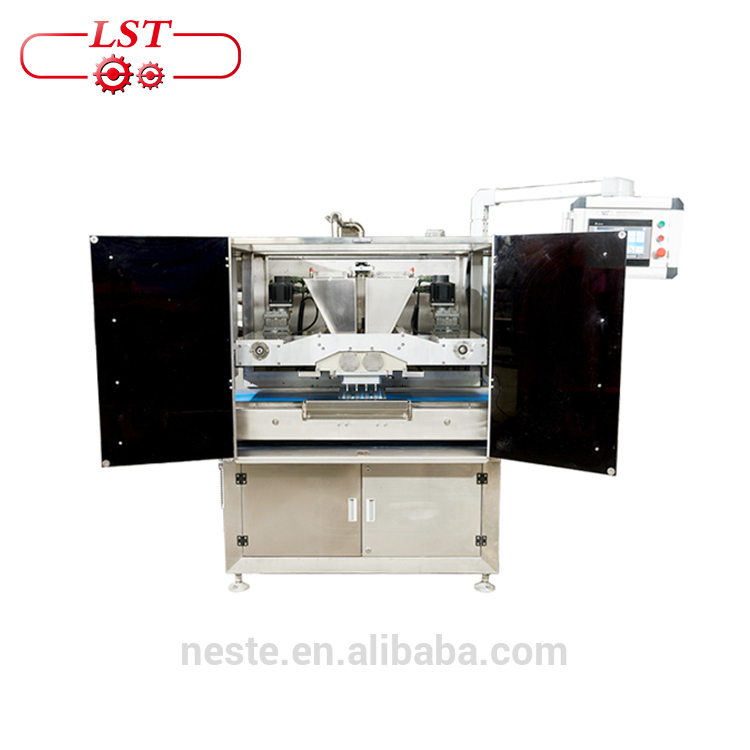

New Design 5.5 L Chocolate Tempering Machine Small Chocolate Tempering Machine Chocolate Dispensing Machine

- Applicable Industries:

-

Food & Beverage Factory

- After Warranty Service:

-

Online support

- Local Service Location:

-

None

- Showroom Location:

-

Malaysia

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380V/50HZ/Three Phase

- Power(W):

-

5Kw

- Dimension(L*W*H):

-

390*460*830mm

- Weight:

-

55kg

- Certification:

-

CE

- Application fields:

-

Snack food factory, Beverage Factory

- Raw material:

-

Milk, chocolate, chocolate food

- Output product name:

-

chocolate

- Key Selling Points:

-

Energy saving

- Condition:

-

New

- Application:

-

Chocolate

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Product name:

-

chocolate tempering and melting machine

- Usage:

-

chocolate /ice cream used

- Feature:

-

combined with tempering ,melting and dispening

- Color:

-

As your requirements

- Material:

-

Stainless Steel 304

- Delivery time:

-

20 days

- Warranty:

-

1 year

- Machinery Function:

-

melting, tempering

New Design 5.5 L Chocolate Tempering Machine Small Chocolate Tempering Machine Chocolate Dispensing Machine

Nozzels choosen chocolate dispensing melting tempering machine in Chinese factory

Choco-D1 is a chocolate dispenser invented specifically for ice cream parlours and chocolate shops and can be used to top ice cream cones and tubs,to make pretty decorations,etc. CHOCO-D1 is with 5.5L bowl.

Features

1.Removable food grade plastic auger screw,easy for cleaning enables quick chocolate change.

2.Two motors, one for the pump and the other for the stirrer, for enhanced motor life over the long-term.

3.Machine can be built in the counter.

4.Multiple control method. Automatic dosing,intermittent dosing,button and pedal control dosing. Chocolate flow is adjustable.

5.Night-mode to keep chocolate melted and to keep low power consumption when the equipment is not used. Temperature can be set accordingly in different cases.

6.Auger screw can rotate in different direction, a highly useful function to clean and empty the nozzle.

7.When step on pedal, the chocolate will be pumped up. While step off the pedal, the chocolate in the auger screw will be sucked back to the heat preservation zone.

8.Separate temperature control system for bowl and auger part.

9.Temperature of the bowl and pump can be set according to your special needs all by yourself. Temperature limit is 65℃.

10.Pre-set temperature for different process. e.g 55℃ for melting , 38℃for storing and serving. Then machine will automatically keep temperature at 55℃ when melting. After fully melted, heating system will stop working till temperature drops to 38℃ and will hold it at 38℃ for serving customer.

11.Packing List:

1 * Dispenser main unit

1 * Pedal

1 * Power cable

1 * Standard Elbow Pipe

1 * Tool + Repair kit

Products show

Nozzels choosen chocolate dispensing melting tempering machine in Chinese factory

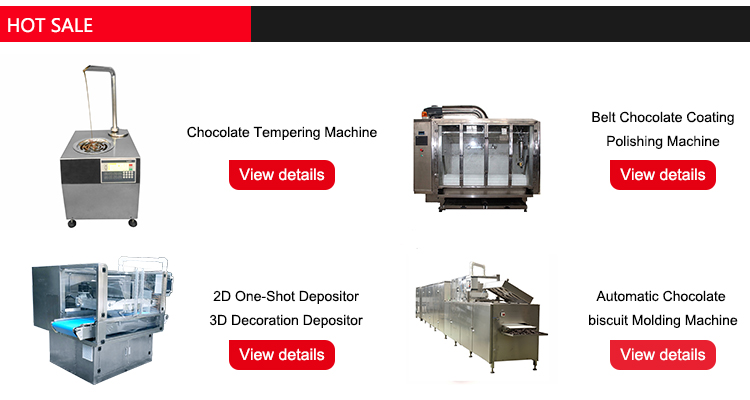

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Nozzels choosen chocolate dispensing melting tempering machine in Chinese factory

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.