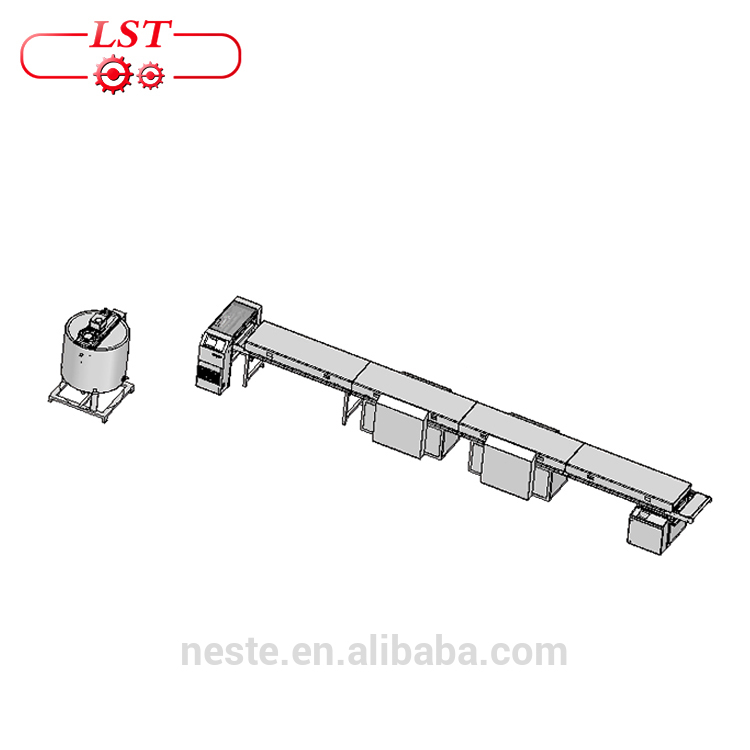

LST150H Small Chocolate Melting Tank Machine Chocolate Holding And Warm Keeping Equipment

- Condition:

-

New, New

- Applicable Industries:

-

Food & Beverage Factory

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380V/415V

- Power(W):

-

2.2

- Dimension(L*W*H):

-

700*700*1600mm

- Weight:

-

120kg

- Certification:

-

CE Certificate

- Warranty:

-

1 year

- Application fields:

-

Snack food factory

- Application:

-

Chocolate

- After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

LST150H Small Chocolate Melting Tank Machine Chocolate Holding And Warm Keeping Equipment

Specifications

Chocolate tempering machine :

1, temperature adjustment

2, melting and storage function

3, with scraper, mixer and stir device

Features of Chocolate Melting machine :

|

Name |

Model |

Main use |

Volum |

Voltage |

Over Dimensions |

|

Mini melting tank |

BWG04 |

Melt,storage,Heat preservation |

4KG |

Single-phase,220V-240V |

240*295*230mm |

|

Mini melting tank |

BWG08 |

Melt,storage,Heat preservation |

8KG |

Single-phase,220V-240V |

410*295*230mm |

|

Mini melting tank |

BWG18 |

Melt,storage,Heat preservation |

18KG |

Single-phase,220V-240V |

605*350*230mm |

|

Tempering tank |

TWG75 |

Tempering&Mixer |

75KG |

3-phase,415V |

900*1400mm |

|

Tempering tank |

TWG150 |

Melt,storage,Heat preservation |

150KG |

3-phase,415V |

900*1500mm |

|

Heat preservation tank |

BWG250 |

Heat preservation&Mixer |

250KG |

3-phase,415V |

1100*800*1600mm |

Features of Chocolate tempering machine :

1, temperature adjustment

2, melting and storage function

3, with scraper, mixer and stir device

4, stainless steel

5, digital temperature control system

6, with water interlayer heating equipment, can be used for external heating and heat preservation

Introduction of Chocolate tempering machine :

Our chocolate melting and tempering mixer machine tank from 75kg to 6000kg, and we also can specially made according to your special needs. It can be used for melting, storage and heat maintaining for chocolate, axunge and similar coating materials.

The stainless steel tank has a sandwich with constant temperature control, and a strong mixing and scraper device inside.

Other components including a water interlayer heating equipment, can be used for external heating, heat preservation and insulation.

Parameter of Chocolate tempering machine :

Chocolate tempering machine:

|

Model |

Max capacity |

Heating style |

Power |

Power supply |

Shell size |

Net weight |

Price |

|

LSTTW10 |

10kg/batch |

electrical heating |

1.2kW |

Single phase/220V |

560 x 600 x 550mm |

40kgs |

USD2500/ FOB SHANGHAI |

|

LSTTW30 |

30kg/batch |

electrical heating |

3kW |

Single phase/220V |

900 x 750 x 950mm |

180kgs |

USD4000/ FOB SHANGHAI |

|

LSTTW60 |

60kg/batch |

electrical heating |

4.5kW |

Single phase/220V |

1100 x 800 x 1150mm |

260kgs |

USD6500/ FOB SHANGHAI |

Option:

If need the water chiller to provide cooled water to LST-60 for tempering function (for pure chocolate tempering), the price for the water chiller is:USD3500.-/ set.

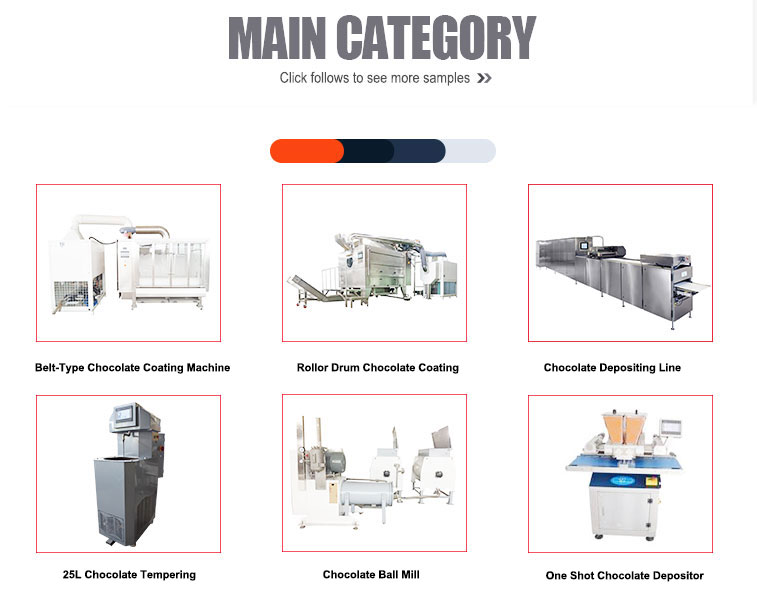

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Our Services

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account. A service charges of USD 60.00/day per technician applies.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.