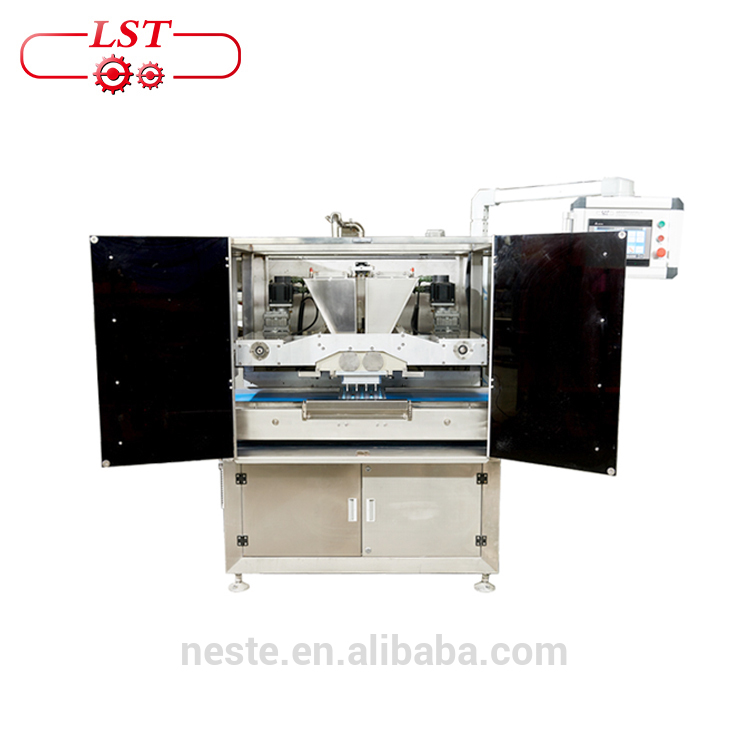

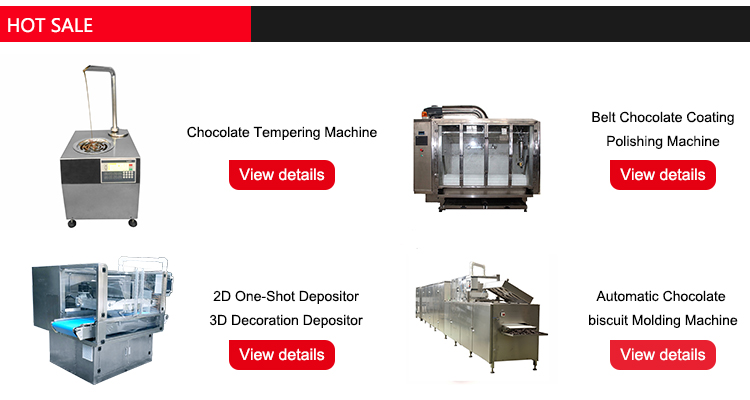

LST Quality chocolate bar making machine production line chocolate stick biscuit molding machine

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

330/380V

- Power(W):

-

27kw

- Dimension(L*W*H):

-

18500*1210*2500mm

- Weight:

-

6500kg

- Certification:

-

CE ISO

- Warranty:

-

1 year

- After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

- Application fields:

-

Snack food factory, Beverage Factory

- Machinery Function:

-

depositing

- Raw material:

-

Nuts, chocolate

- Output product name:

-

chocolate

- Condition:

-

New

- Application:

-

Chocolate

LST Quality chocolate bar making machine production line chocolate stick biscuit molding machine

Cocoa butter Melting Tank

Use:

The cocoa butter melting tank is used for melting the cocoa butter. This tank could be heated by the electrical immersion heater. The tank wears hot-water jacket.

|

Capacity: |

360kg |

|

Motor power: |

8kw |

|

Shape: |

Rectangle or cylinder |

|

Material: |

Inner: stainless steel, outer: mild steel |

|

Outside dimension: |

1900*970*1250mm |

Sugar grinding machine:

USE:

The sugar grinding machine is a kind of chocolate machine mainly used for secondary grinding of granulated sugar.

|

Production capacity: |

250kg/h |

|

Feeding granularity: |

0.5~2mm |

|

Average grain: |

80-100 mesh |

|

Main shaft power: |

7.5kw |

|

Feed motor power: |

1.5kw |

|

Main shaft Rotation speed: |

3800r/min |

|

Feed spindle rotation speed: |

217r/min |

|

Net weight: |

500kg |

|

Outside dimension |

1240*960*1733mm |

Chocolate conche:

USE:

1).The chocolate conche machine is one of the major chocolate machine in the chocolate production line which are used for the fine grinding of chocolate material.

2).The fine grinding time is about 14~20 hours, the average granularity can achieve 20μm.

3).This chocolate machine has many merits such as tight structure, easy operation, convenient maintenance, few one-off investment, and so on.

4).It is suitable especially for the technical request of medium chocolate and candy factory.

|

Maximum capacity(L): |

1000L |

|

Grinding Fineness(micron): |

20~25 |

|

Main Axle Rotating Speed(rpm): |

35 |

|

Grinding time(h): |

16~22 |

|

Main motor power(kw): |

18.5 |

|

Electrical heating power(kw): |

2*2 |

|

Weight(kg): |

3050 |

|

Outside dimensions(mm): |

2627*1280*1520 |

Chocolate holding tank

USE:

The chocolate holding tank is a necessary equipment in chocolate production line. It wears double warm-water jacket which used for temperature storage of fine ground chocolate paste.So that to meet the technical request of chocolate production and the request of continuous production.

This chocolate tank has functions of temperature decrease, rise and preservation.

Besides it has the functions of degasification, desmelling, dehydration and preventing the chocolate paste from the separation of oil and grease and so on.

|

Model: |

JY1000 |

|

Maximum capacity |

1000kg |

|

Motor power: |

2.2kw |

|

Stirring Rotational Speed: |

24 rpm |

|

Whisk Rotational Direction: |

Clockwise (Viewed from above) |

|

Electric Heater Power: |

4kw |

|

Tank Interlayer Water Temperature: |

55°C (Warm-up temperature of chocolate mass) |

|

Net weight: |

1000kg |

|

Outside dimension: |

(Diameter)1220*(Height)1850mm |

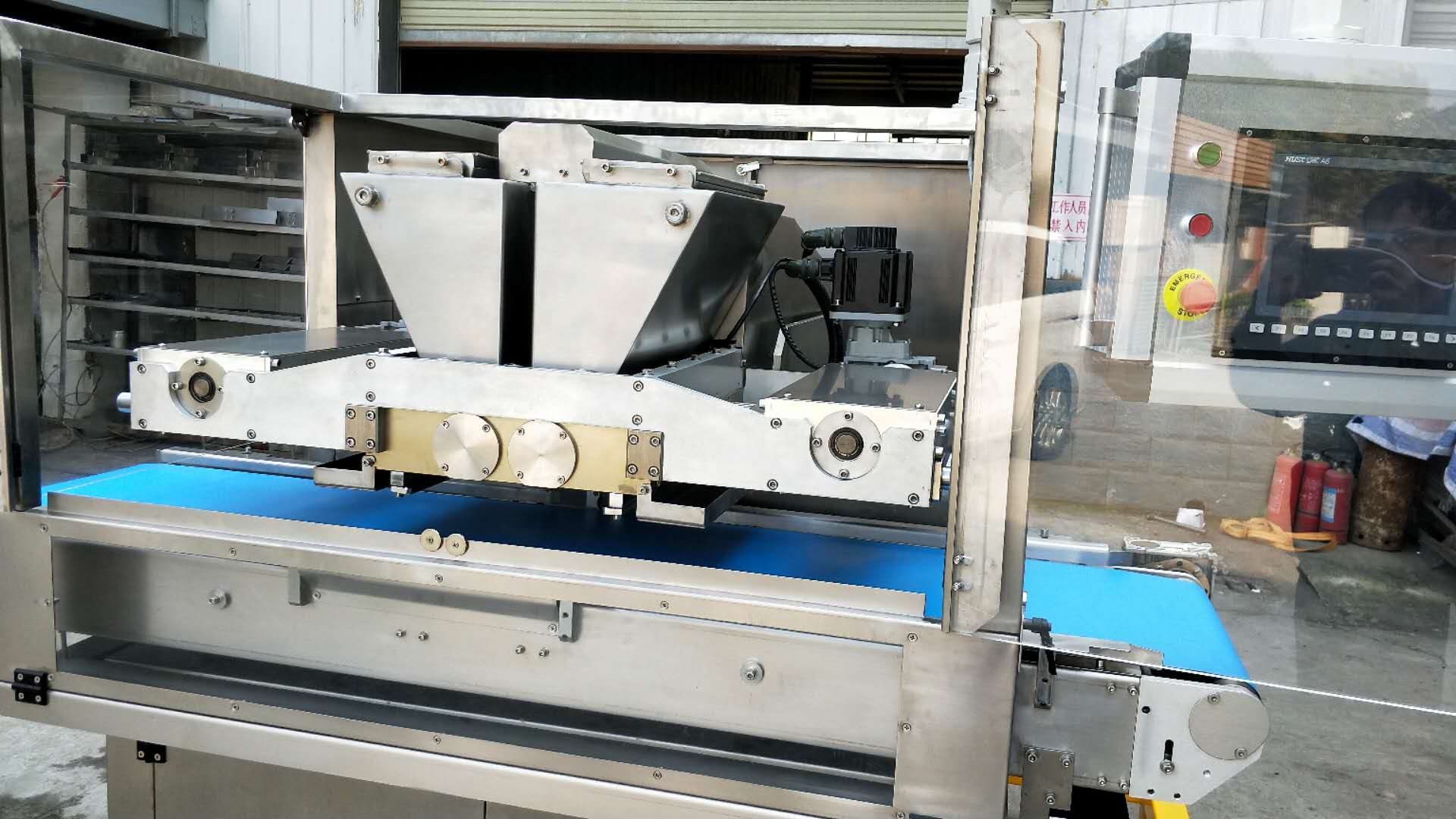

Chocolate depositing machine:

USE:

1).This chocolate depositing line can produce pure solid chocolate, center filling chocolate, two color chocolate, nuts mixed chocolate with nuts mixing machine. Chocolate can be compound chocolate and real chocolate.

2).Products can be manufactured with biscuits or wafers simply by installing the relevant biscuit feeding units.

3).Chocolate depositing line can complete automatic feeding mould, baking mould, depositing, vibrating mould, cooling, de-moulding, conveying empty moulds for cycle AUTOMATICALLY and dosage system is mechanical.

4).This depositing line has merits of high productivity, accurate dosing, smooth surface of chocolate etc.

|

Production capacity: |

800 – 2500kg/shift |

|

Depositing times: |

20 – 25times/minute |

|

Dosage system: |

mechanical |

|

Mechanical vibrating frequency: |

200 – 1000times/minute. |

|

Molds vibrating amplitude: |

0 – 3mm, adjustable |

|

Cooling time: |

18 – 30min |

|

Cooling temperature: |

5 – 10°C |

|

Cooling tunnel length: |

8.2m * 8 Layers |

|

Time of baking molds: |

20 – 36 seconds |

|

Temperature of baking molds: |

35 – 40°C |

|

Length of baking molds: |

1.4m |

|

Refrigeration capacity: |

20000 – 25000kcal/h (10 HP COPERLAND) |

|

Evaporator area: |

80 square meters |

|

Quantity of moulds: |

300 pieces |

|

Dimension of moulds: |

standard 275×175×30mm |

|

Total Power of machine: |

17.4kw |

|

Dimensions: |

16000×1000×1800(L×W×H, mm) |

|

Weight of the machine: |

3500kg |

Characteristics:

- PLC control, auto-frequency control

- man-machine touch interface to detect the levels of the liquid and solid material. Overload protection to alarm when there is something wrong, and to show it on the touch screen

- programming storage of the products to change the chocolate color and products every 15 minutes. More stable when running with the prescription

- separated heating and control system. The heating system keeps the chocolate in constant temperature when the control system is powered off, so the service life of the control system is longer.

- it can mix chocolate, nut butter, fruit, or cereal with other particle food; the product loafs are varied and can be customized

- equipped with 2 high precision cam rotor pumps to mix the material continuously. The batching system and the high precision cam rotor pumps can keep the stable proportion of the chocolate during producing

- during the production, the mixing materials can be detected by the sensor, and supplemented by the transducer. The whole producing process is controlled by the sensor, and there is no need to stop.

- made of stainless steel ,and matched with special accessories like magnetic rodless cylinder, which can meet the food sanitary requirement

- adopted with the imported technology, we improve our machines according to the after service and testing report. By customers’ requirement, we add another set of material conveying unit and chocolate conveying unite to diversify our products

- the whole production line includes: moulds, mixing and forming unit, cooling unit, packaging unit

- the corn mould clamping device can be added according to the customers’ requirements

technical features:

production capacity: 2000-6000KG/shift

total power:27KW

air supply pressure:0.6Mpa

overall dimension:18500×1210×1800mm

mould dimension:400×300×30mm(the moulds and the shapes of the products can be customized )

mould output:10-16pieces/min

It is good to produce pure chocolate, center-filled ,double-colored chocolate and crispy rice chocolate, with accurate pouring amount and easy operation.

1. Payment: T/T in advance. 40% down payment, 60% against acceptance from customers

2. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

3. Customization is available.

5. What’s the information should I let you know if I want to get a full quotation?

Bag type, size, weight of material, type of material, thickness, printing, colors, quantity

6. When we create our own artwork design, what kind of format is available for you?

The popular format: AI, JPEG, CDR,PSD, TIF

7. Wooden case packed with machine and English manule

8. Transformer is provided

9. Technical manual in English is provided

10. The machine is stainless steel

11. In the line of exporting packing material