LST New Publish

-

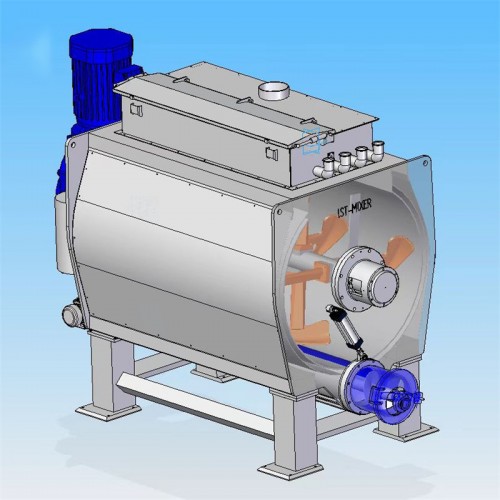

1000L high-quality real cocoa butter chocolate conching machine

The Chocolate Conche and Refiner is the main machine for chocolate production and can be used for the refining and refining of chocolate mass/blocks. Through prolonged stirring, fermentation removes odors and enhances the flavor of cocoa. Also suitable for the refining of jams, peanut butter or other liquors/pulps.

-

Sanitary food grade stainless steel chocolate rotary lobe pump for chocolate

●Product Introduction The pump is used for conveying and lifting chocolate paste between chocolate machines.It wears heated-water jacket to keep the paste warm. ●Features Chocolate Factory use Jackted Chocolate Pump For factory use , Speed controller, Durable and good performance. ●Application ●Parameter Chocolate pump 0-0.4/0.5T/H 1T/H 2T/H Capacity 500kg/h 1000kg/h 2000kg/h Output rotating speed 100rmp/min 177rmp/min - Viscosity 10000-20000cp 10000-20000cp - Rotary le... -

250L per hour chocolate continuous tempering machine for natural chocolate tempering automatic temper

The chocolate tempering machine is specially for natural cocoa butter chocolates.After tempering ,the chocolate products will be with good flavor and long-term storage. There are options for you to equip Tempering machine with Enrobing machine ( as shown in the video) or with depositing heads, according to your different product demands.

-

LST Automatic Chocolate Enrobing Line Wafer Chocolate Machine Tempering Coating&Enrobing Machine 8/15/30/60kg available

The table-top chocolate moulding machine is a very compact machine that is ideal as an entry-level or secondary machine.It is suitable for chocolatiers or small patisserie or pastry kitchen even for market store to mould pure chocolate or cocoa butter to various of pattern shape.

-

LST small vertical cooling tunnel 275mm mini chocolate molding cooling machine vertical cooler for food factory

Vertical cooling tunnels are universally used for product cooling after molding. Such as filled candy, hard candy, taffy candy, chocolate and many other confectionery products. After conveying to cooling tunnel, products will be cooled by special cooling air.

-

LST Full Automatic Chocolate 2D/3D One-Shot Depositor Production Line

In addition to the production of ordinary solid chocolate, this equipment can also produce three-dimensional and multi-color(3D), double color chocolate(2D),filled chocolate, particle mixed chocolate, accurately depositing rate and easy operation.

-

Chocolate Holding Tank with SS304 Material 50-3000L

Chocolate holding/storage tank is used for holding the finely grinded paste. This chocolate tank has functions of temperature decrease, increase and preservation. Besides, it also can prevent fat separation.

-

Belt Chocolate/Powder Coating and Polishing Machine

Chocolate Coating machine and Chocolate Polishing machine are mainly used in stuffed products with peanuts,almonds, raisin,puffed rice balls,Jelly candies, hard candies ,QQ candies etc.

-

LST Chocolate Fat Melting Tank 500-2000 KG Capacity Fat Cocoa Butter Melting Machine

The cocoa fat melting tank is used for melting solid cocoa butter or fat to liquid. Chocolate melting machine is the main equipment in the chocolate production line, and used before the production of chocolate paste.

-

LST Factory 400-800kg/h full automatic chocolate production line with cooling tunnel

This Chocolate depositing line is a high tech full automatic chocolate machine for chocolate molding. The production process include mould heating, chocolate depositing, mould vibrating, mould conveying, cooling and demolding. This line has been widely applied in production of pure solid chocolate, center filled chocolate, double-colored chocolate, particle mixed chocolate, biscuit chocolate,etc.

-

LST chocolate making machine large capacity ball mill machine

Comparing with refiner, ball mill has been improved with the advantages of low energy consumption, high productivity, low noise, super low metal content, easy to clean, one-touch operation, etc. In this way, it has shortened 8-10 times of milling time and saved 4-6 times of energy consumption. With leading advanced technology and imported accessories with original packing, equipment performance and products’ quality is guaranteed.

-

LST 2022 latest cooling tunnel with enrobing machine for bulk production

Air cooling tunnels are universally used for product cooling after molding. Such as filled candy, hard candy, taffy candy, chocolate and many other confectionery products. After conveying to cooling tunnel, products will be cooled by special cooling air.