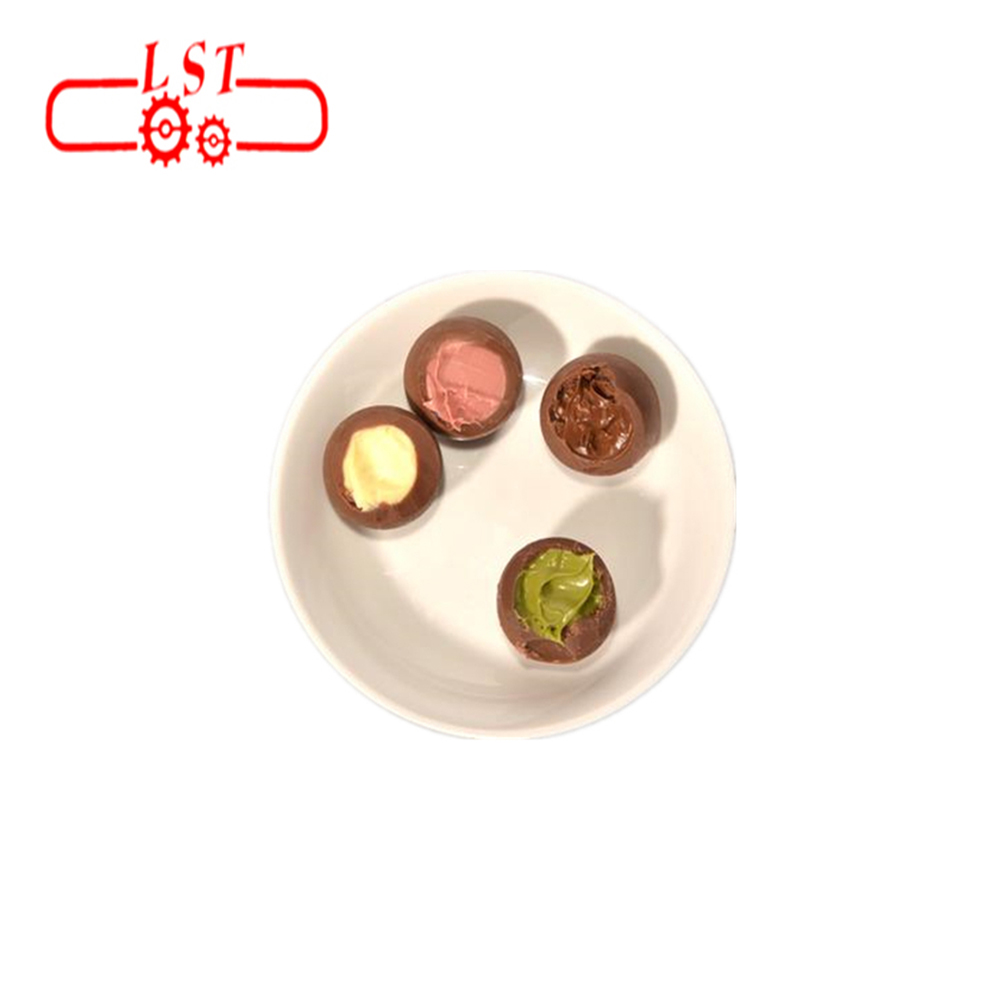

LST Chocolate Ball Making Machine Center filled chocolate ball machine

- Applicable Industries:

-

Food & Beverage Factory

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380V Or Customized

- Power(W):

-

14kw

- Dimension(L*W*H):

-

2700*1200*1650

- Weight:

-

500kg

- Certification:

-

CE ISO

- Warranty:

-

1 year

- After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

- Application fields:

-

Snack food factory

- Machinery Function:

-

depositor

- Raw material:

-

chocolate

- Output product name:

-

chocolate

- Condition:

-

New

- Application:

-

Chocolate

- Name:

-

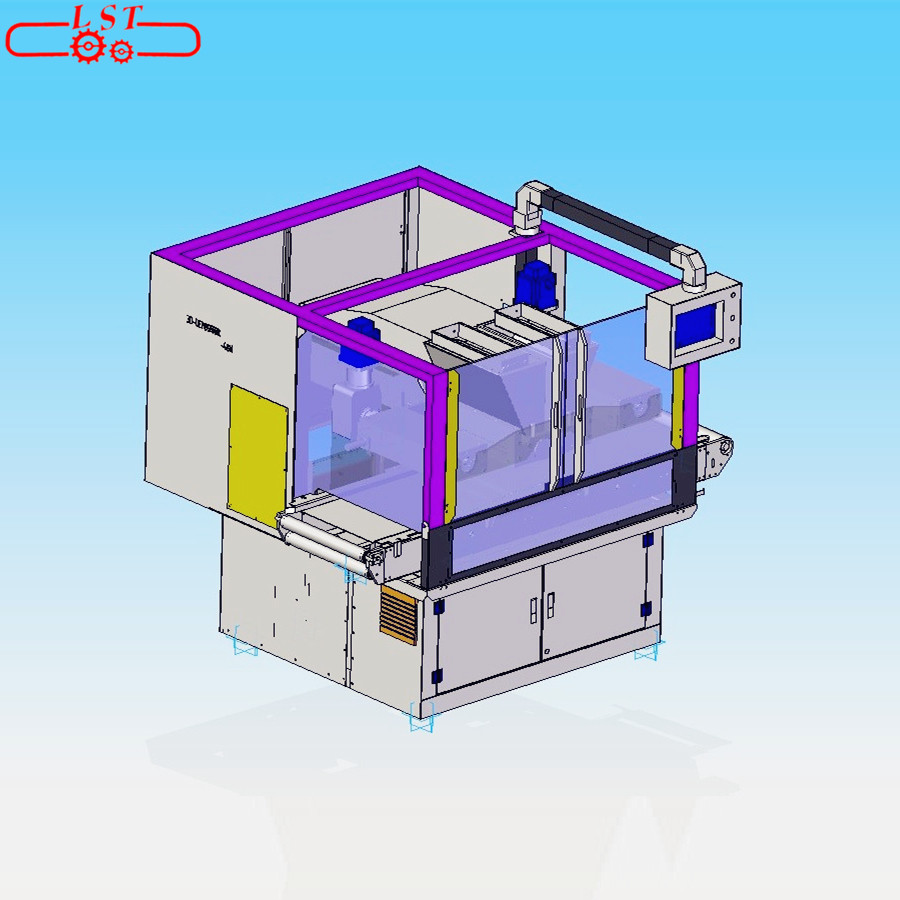

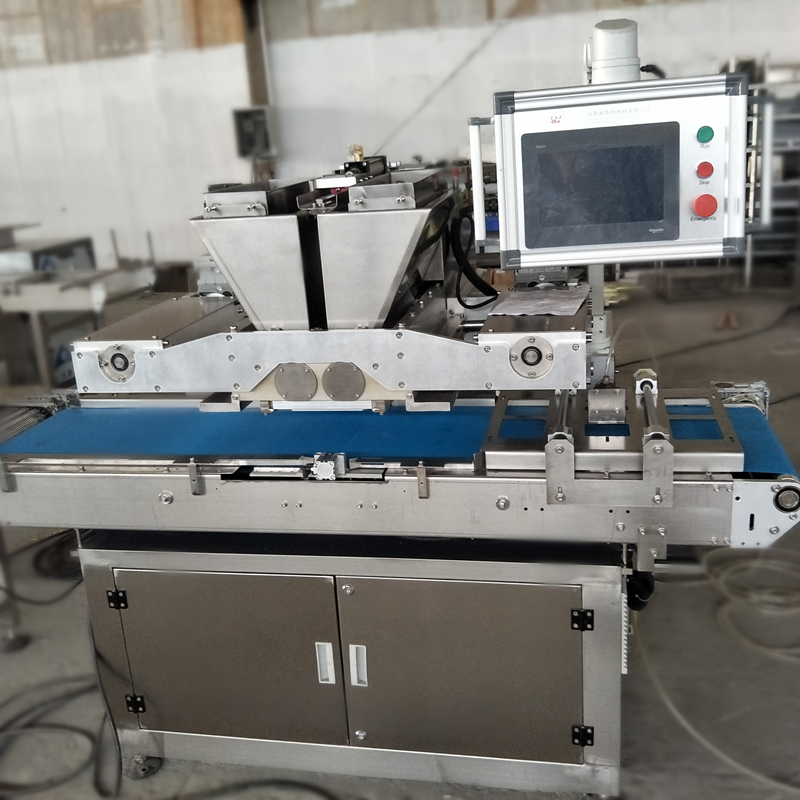

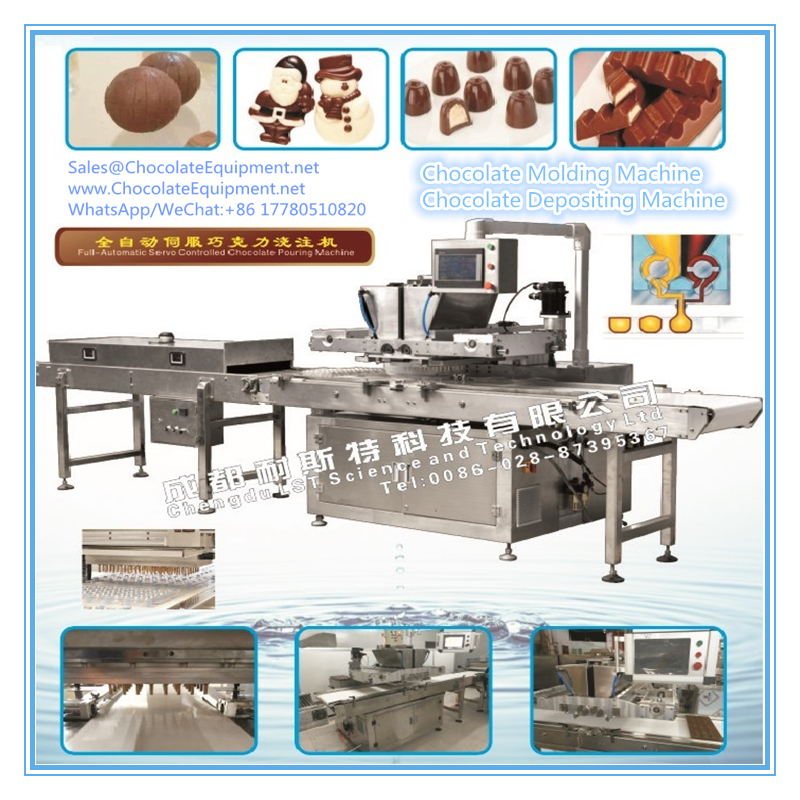

Full Automatic Servo-controlled Chocolate Ball Molding Machine

- Customize:

-

Support

LST Chocolate Ball Making Machine Center filled chocolate ball machine

Main parameters:*Support Customization

|

Productivity |

Nozzles |

Power |

Air supply |

Power supply |

Net Weight |

Dimension |

|

8-18 moulds/min |

48/72/96*2 |

22kw |

4MP |

Customized |

500kg |

4900-1680-1800mm |

Servo Controlled Chocolate depositing Machine

This machine is an advanced and exclusive equipment for chocolate molding , the whole producing process includes mould heating, conveying and depositing. It is a fully automatic producing equipment, which is good to produce pure chocolate, center-filled ,double-colored chocolate and crispy rice chocolate, with accurate pouring amount and easy operation.

This fully automatic chocolate servo controlled pouring machine is equipped with international famous brand servo motor and controlled by PLC system. It is a multi-functional chocolate pouring machine with pneumatic components. As the new generation of chocolate food machinery, it is suitable for small and medium-sized food enterprises to produce personalized, diversified chocolate candy. This machine is designed according to the international general standard. It can work individually, and also can be combined with other equipment. Flexibility is the main characteristic for this equipment, which makes it convenient to switch from different products.

Depositing Head

a. 12/14 stainless steel piston-rods offer quantitative pouring controlled by dual servo motors.

b. SMC rotary valve cylinder control chocolate valve.

c. stainless steel pot with interlayer . Hopper is equipped with thermal insulation system(hot water circulation).

d. Special assemble and disassemble mechanism enables a very quick switch of distribution plate when needed for different

products. At the same time. It is more easy for cleaning of the unit.

e. The particular structure of nozzle ensures uniform thickness of the filling layer and covering layer.

f. The number of pouring nozzle is 48*2.