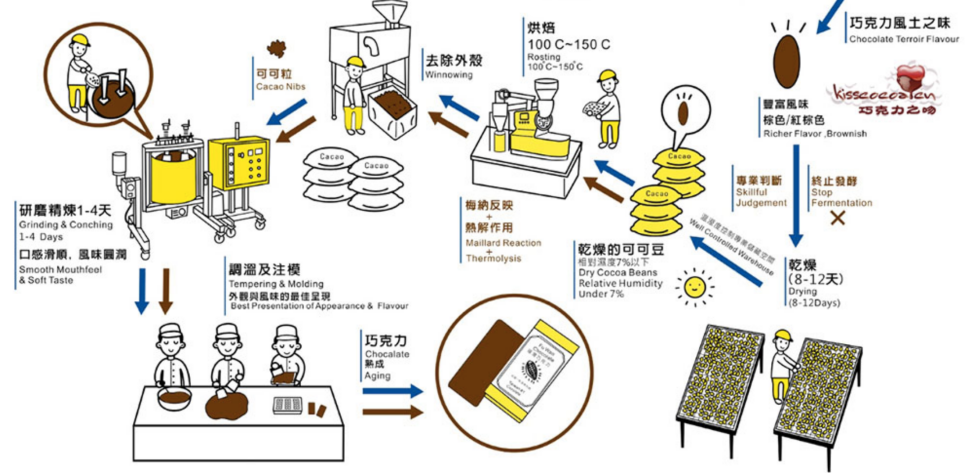

Lub hnub-qhuav cocoa taum raug xa mus rau lub Hoobkas, pib nws txoj kev hloov pauv ... Los ntawm cov taum iab mus rau cov qhob noom xim kasfes qab, yuav tsum muaj cov txheej txheem ua tiav.Raws li cov txheej txheem ua, nws tuaj yeem muab faib ua 3 txheej txheem, pulping Nias, zoo sib tsoo thiab ua kom zoo, hloov kho kub thiab molding.

Tam sim no, ntau qhov chaw hauv ntiaj teb tseem tuav txoj hauv kev qub ntawm kev ua cov noob taum cocoa, tab sis xuas tes ua los ntawm cocoa taum mus rau chocolate, saj yuav ntxhib.Yog li tsab xov xwm no mas tham txogyuav ua li cas siv tshuab ua kom tiav cov txheej txheem no

1. Sib tsoo thiab Pressing

Cocoa taum yog crushed thiab nias kom tau cocoa cawv, cocoa butter, thiab cocoa hmoov.

Ua ntej pulping thiab nias, nws yuav tsum mus los ntawm cov txheej txheem ntawm taum xaiv, taum ntxuav, roasting, winnowing thiab crushing.Kev xaiv taum, raws li lub npe qhia, yog txhawm rau tshuaj xyuas cov taum tsis tsim nyog lossis cov taum tsis zoo.Ntxuav taum, yaug thiab qhuav.Tom qab ntawd pib ci, winnow, crush, thiab finely grind kom tau cocoa cawv, thiab lub cocoa cawv loj yog txias kom tau cocoa cawv loj.Lub cocoa cawv yog nias los ntawm cov roj nias kom rho tawm cov cocoa butter.Cocoa hmoov yog lub ncuav mog qab zib cocoa uas tseem tshuav tom qab lub cocoa kua yog nyem kom tshem tawm cov roj, thiab ces crushed, av, thiab sieved kom tau ib tug brownish-liab hmoov.

1.1 Baking - Cocoa Roaster Tshuab

Cocoa taum roasted ntawm qhov kub ntawm 100 thiab 120 ° C.Tag nrho cov txheej txheem yuav siv sij hawm 30 feeb los xyuas kom meej tias txhua cocoa taum exudes ib tug nplua nuj cocoa tsw tom qab roasting.

1.2 Winnowing thiab crushing - Cocoa Cracking & Winnowing Tshuab

Tom qab roasting, cov taum cocoa ua tsaus rau hauv cov xim, ze rau xim av xim av ntawm chocolate nws tus kheej.Cocoa taum txias sai sai, thiab cov plhaub nyias uas ua rau lub sijhawm ci yuav tsum tau muab tshem tawm, xav kom cov kiv cua tshuab tawm ntawm daim tawv nqaij.Cov nibs, siv tau ib feem ntawm cocoa taum, yog sab laug thiab hauv av rau hauv nibs.Cov kauj ruam no yog hu ua winnowing thiab crushing, thiab muaj ntau ntau txoj kev sib txawv, qhov trickiest ntawm uas yog tshem tawm ntawm daim tawv nqaij kiag li tsis poob hauv av taum.Yog tias muaj tawv nqaij tawv sib xyaw nrog chocolate, nws yuav ua rau muaj qhov tsw qab.

Cov txheej txheem no tseem tuaj yeem ua tiav hauv theem ua ntej roasting ua ntej roasting.Tag nrho cov taum yuav tsum tau roasted nyob rau hauv ib puag ncig ntawm 400 ° C rau 100 vib nas this, kom cov taum cocoa yooj yim los ntawm cov taum ntawm daim tawv nqaij tom qab cov txheej txheem no.Nws yog ces crushed rau hauv me me nplej, tej cocoa tawv raug tshem tawm nyob rau hauv tus txheej txheem, ua ntej yuav roasted.

Hauv feem ntau cov chaw tsim khoom, cov txheej txheem no yog ua tiav nrog "kiv cua crusher", lub tshuab loj loj uas tshuab tawm lub hulls.Lub tshuab hla cov taum los ntawm serrated cones kom lawv tawg ntau dua li crushed.Thaum lub sij hawm tus txheej txheem, ib tug series ntawm mechanical sieves cais cov pieces mus rau hauv qhov sib txawv qhov ntau thiab tsawg thaum cov kiv cua tshuab lub nyias nyias lub plhaub kom deb ntawm cov pulpy khoom.

1.3 Kev sib tsoo zoo - Colloid Mill & Melanger

Nyob rau hauv lub chaw tsim khoom lag luam niaj hnub no, koj tuaj yeem xaiv siv lub tshuab colloid lossis lub pob zeb zeb los zom cov taum crushed rau hauv slurry.

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm lub tshuab colloid yog shearing, sib tsoo, thiab kev kub ceev stirring.Cov txheej txheem sib tsoo yuav siv qhov chaw sib txheeb ntawm ob tus hniav, ib qho tig ntawm kev kub ceev thaum lwm qhov tseem nyob ruaj khov.Ntxiv rau qhov kev vibration siab thiab kev kub ceev eddy tam sim no, cov khoom nruab nrab ntawm cov hniav kuj raug rau cov shear muaj zog thiab hnav.Cov khoom yuav sib npaug pulverized, dispersed thiab emulsified.

Pob zeb zeb siv ob lub pob zeb granite rau kev sib tsoo tas li.Lub cocoa butter uas muaj nyob rau hauv lub cocoa taum nibs kuj maj mam tso tawm tom qab ua finely av nyob rau hauv lub sij hawm ntev ntawm tsis-nres dov, tsim ib tug tuab theem slurry, uas condenses rau hauv lumps tom qab txias.

Qhov tseeb, thaum nws los txog rau theem ntawm kev sib tsoo zoo thiab ua kom zoo dua qub, nws tsis muaj dab tsi ntau dua li kev hloov mus rau qhov zoo "sib tsoo" rau kev sib tsoo tas li.

Cocoa butter ua cov roj nplua nyeem raws li cov suab thaj thiab cocoa hmoov yog hauv av rau hauv cov khoom me me.Tib neeg lub qhov ncauj tuaj yeem saj cov khoom loj dua 20 microns.Txij li txhua tus neeg nyiam txaus siab rau super du thiab nplua nuj chocolate, peb yuav tsum xyuas kom meej tias tag nrho cov khoom siv hauv cov qhob noom xim kasfes me dua qhov loj me.Qhov ntawd yog hais tias, cov hmoov cocoa yuav tsum yog hauv av kom tsawg dua 20 microns, uas yog cov kauj ruam tom ntej ntawm kev ua kom zoo thiab ua kom zoo dua qub, yog li nws yuav tsum tau sib tsoo kom ntev dua.

Melanger

Colloid Mill

1.4 Extraction-Oil Xovxwm Tshuab & Hmoov Sib Tsoo Tshuab

Cocoa butter thiab cocoa hmoov muaj cov kua cocoa lossis kua ua kua tom qab pulping, uas yuav tsum tau muab rho tawm los ntawm nias.Nyem lub cocoa cawv kom cais cov cocoa butter, uas muaj roj cov ntsiab lus ntawm 100%, thiab tom qab ntawd zom cov ncuav mog qab zib uas tseem tshuav los ua cov hmoov cocoa, nrog cov roj ntawm 10-22%.

Muab cov kua cocoa tso rau hauv cov roj tsis siv neeg nias, thiab nws yuav raug tshem tawm los ntawm lub piston ntawm lub tog raj kheej roj, thiab cov roj yuav ntws tawm ntawm qhov sib tsoo, thiab nkag mus rau hauv cov roj tank los ntawm cov roj tau txais phaj los khaws cov roj.

Muaj ntau ntau cov riam txav (los yog prisms los yog rauj taub hau) nyob rau hauv lub rotating log nyob rau hauv lub zeb, thiab ib tug txheej ntawm ruaj riam nyob rau hauv lub nplhaib iav.Thaum lub sij hawm txiav kev sib tsoo ntawm cov riam txav thiab cov riam ruaj, cov khoom yog crushed.Nyob rau tib lub sijhawm, lub crushing chamber generates airflow, uas tso cov cua sov ua ke nrog cov khoom tiav los ntawm qhov screen.

2. Refining-Chocolate Conching Tshuab

Hauv kev nrhiav cov qhob noom xim kasfes dawb huv, koj tsis tas yuav ntxiv cov khoom pabcuam, txawm tias cov suab thaj yooj yim tshaj plaws, tab sis qhov no yog qhov kev xaiv ntawm cov neeg tsawg tom qab tag nrho.Ntxiv nrog rau cocoa pawg, cocoa butter thiab cocoa hmoov, cov khoom siv chocolate nrov kuj xav tau cov khoom xyaw xws li qab zib, khoom noj siv mis, lecithin, flavour thiab surfactants.Qhov no yuav tsum tau refining thiab refining.Kev sib tsoo thiab ua kom zoo dua qub yog qhov txuas ntxiv ntawm cov txheej txheem dhau los.Txawm hais tias qhov zoo ntawm cov khoom siv chocolate tom qab sib tsoo tau mus txog qhov yuav tsum tau ua, nws tsis yog lubricated txaus thiab saj tsis txaus siab.Ntau yam ntaub ntawv tseem tsis tau tag nrho ua ke rau hauv ib qho tshwj xeeb tsw.Qee qhov tsis hnov tsw tseem yog tam sim no, yog li yuav tsum tau ua kom zoo ntxiv..

Lub tshuab no tau tsim los ntawm Rudolph Lindt (tus tsim ntawm Lindt 5 grams) nyob rau xyoo 19th lig.Qhov laj thawj yog vim li cas nws thiaj li hu ua "Conching" yog vim nws yog Ameslikas ib lub voj voog zoo li lub plhaub plhaub.Lub conch (conche) yog lub npe los ntawm Spanish "concha", uas txhais tau tias plhaub.Cov khoom siv ua kua chocolate yog tig rov qab los ntawm cov menyuam rau lub sijhawm ntev hauv lub tank, thawb thiab rub kom tau txais cov kua nplaum me me, aroma fusion thiab saj tsis txawv, cov txheej txheem no hu ua "sib tsoo thiab ua kom zoo"

Thaum kho dua tshiab, ntau yam khoom pabcuam tuaj yeem muab ntxiv.

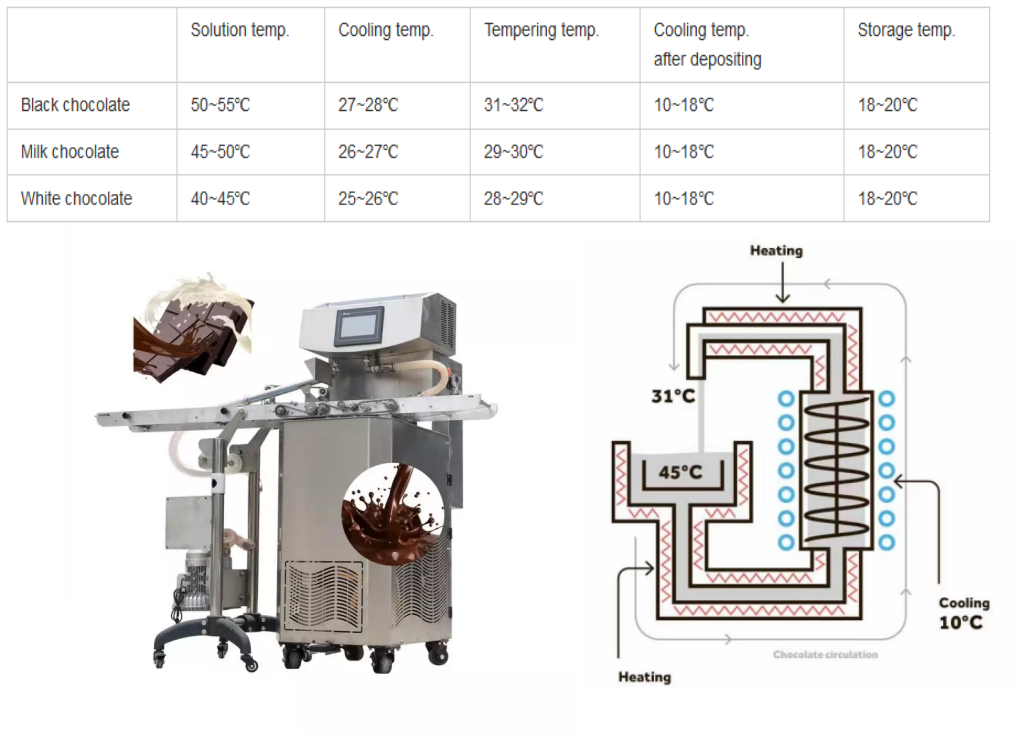

3.Temper & Moulds-Tempering Tshuab & Moulding

Tempering yog cov kauj ruam kawg hauv kev tsim khoom thiab muaj kev cuam tshuam loj rau qhov kawg ntawm chocolate kev paub rau cov neeg siv khoom.Koj puas tau muaj ib qho chocolate uas yog crumbly thiab muaj opaque dawb zaj duab xis sab nraum?Txawm hais tias lub tempering tsis ua tiav los yog ib yam dab tsi tsis ncaj ncees lawm nrog cov khoom xyaw.

Yuav kom nkag mus rau hauv qab ntawm lo lus nug no, koj yuav tsum paub ob peb yam txog cocoa butter.Cocoa butter tso nyiaj rau 48% -57% ntawm qhov hnyav ntawm taum cocoa.Nws yog cov khoom uas ua rau chocolate insoluble nyob rau hauv tes (khoom nyob rau hauv chav tsev kub) tsuas soluble nyob rau hauv lub qhov ncauj (pib yaj nyob rau hauv lub cev kub).Muab ib daim ntawm chocolate rau ntawm koj tus nplaig thiab xav tias nws maj mam yaj hauv koj lub qhov ncauj yog qee qhov ntxim nyiam tshaj plaws ntawm chocolate, thiab nws yog txhua yam ua tsaug rau cocoa butter.

Cocoa butter yog polymorphic, uas txhais tau hais tias, nyob rau hauv sib txawv solidification tej yam kev mob, nws tsim ntau hom crystals, uas yuav ua tau ruaj khov los yog tsis ruaj khov.Cov crystals ruaj khov yog ntim zoo thiab muaj cov ntsiab lus melting ntau dua li cov muaju tsis ruaj khov.Yog li ntawd, peb yuav tsum tau kho qhov kub thiab txias kom ntseeg tau tias cov cocoa butter thiab cocoa butter zoo li daim ntawv siv lead ua ruaj khov tshaj plaws, thiab tom qab ntawd txias nws kom raug kom cov qhob noom xim kasfes muaj luster zoo thiab tsis tawg rau lub sijhawm ntev.Feem ntau cov txheej txheem ntawm tempering chocolate muaj xws li cov kauj ruam hauv qab no

1. Qhuav lub chocolate kom tiav

2. Txias mus rau qhov kub ntawm crystallization

3. Ua kom muaj crystallization

4. Ua kom cov crystals tsis ruaj khov

Qhov ntsuas kub tuaj yeem hloov kho manually, tab sis qhov kub thiab txias yuav tsum yog qhov tseeb.Xaiv lub tshuab chocolate tempering uas tswj qhov kub thiab txias rau qhov sib txawv ntawm qhov kub tsawg dua ± 0.2 tuaj yeem pab koj zoo heev.Lub tempering ntawm txawv chocolates kuj yog tag nrho inconsistent:

Thaum cov chocolate sauce tau raug tempered kom zoo, nws yuav tsum tau zoo li tam sim ntawd, ces txias los kho cov qauv thiab hloov mus rau hauv ib tug ruaj khov lub xeev.Nws tuaj yeem nchuav los ntawm tes lossis los ntawm tshuab.Kev tuav lub ncuav rau hauv pwm tsis yog raws li lub tshuab nchuav, yog li cov kua ntses ntau dhau yuav tsum tau muab pov tseg.Tom qab txias, nws tuaj yeem muab tso rau hauv ib qho zoo nkauj chocolate.

Post lub sij hawm: Nov-28-2022