LST Zoo chocolate bar ua tshuab ntau lawm kab chocolate stick biscuit molding tshuab

- Hom Lub Npe:

- LST

- Qhov Chaw Keeb Kwm:

- Sichuan, Suav teb

- Voltage:

- 330/380V

- Lub zog (W):

- 27 kwv

- Qhov Loj (L * W * H):

- 18500 * 1210 * 2500mm

- Qhov hnyav:

- 6500kg ib

- Ntawv pov thawj:

- CE ISO

- Warranty:

- 1 xyoo

- Kev Pabcuam Tomqab Muag Khoom Muab:

- Field installation, commissioning thiab kev cob qhia, Engineers muaj rau kev pab cuam machinery txawv teb chaws

- Daim ntawv thov teb:

- Khoom noj khoom haus Factory, Beverage Factory

- Machinery Function:

- tso nyiaj

- Cov khoom siv raw:

- Txiv ntseej, chocolate

- Output khoom npe:

- chocolate

- Qhov xwm txheej:

- Tshiab

- Daim ntawv thov:

- Chocolate

LST Zoo chocolate bar ua tshuab ntau lawm kab chocolate stick biscuit molding tshuab

Cocoa butter Melting Tank

Siv:

Lub cocoa butter melting tank yog siv rau melting lub cocoa butter.Lub tank no tuaj yeem ua kom sov los ntawm lub tshuab hluav taws xob immersion.Lub tank hnav lub tsho dej kub.

| Muaj peev xwm: | 360kg ua |

| Lub cev muaj zog: | 8 kwv |

| Cov duab: | Lub tog raj kheej lossis lub tog raj kheej |

| Khoom siv: | Sab hauv: stainless hlau, sab nraud: me me steel |

| Sab nraud dimension: | 1900 * 970 * 1250mm |

Qab zib sib tsoo tshuab:

Siv:

Lub tshuab sib tsoo suab thaj yog ib hom chocolate tshuab siv rau kev sib tsoo ntawm granulated qab zib.

| Muaj peev xwm ntau lawm: | 250kg / h |

| Pub granularity: | 0.5 ~ 2 hli |

| Nruab nrab grain: | 80-100 mesh |

| Main ncej zog: | 7.5 kwm |

| Feed lub cev muaj zog: | 1.5 kwv |

| Main ncej rotation ceev: | 3800 r / min |

| Feed spindle rotation ceev: | 217 r / min |

| Net nyhav: | 500 kg |

| Sab nraud dimension | 1240 * 960 * 1733 hli |

Chocolate pob kws:

Siv:

1) Lub tshuab chocolate conche yog ib lub tshuab chocolate loj hauv cov kab ntau lawm uas yog siv rau kev sib tsoo zoo ntawm cov khoom siv chocolate.

2) Lub sijhawm sib tsoo zoo yog li 14 ~ 20 teev, qhov nruab nrab granularity tuaj yeem ua tiav 20μm.

3) Lub tshuab chocolate no muaj ntau yam zoo xws li cov qauv nruj, kev ua haujlwm yooj yim, kev saib xyuas yooj yim, ob peb qhov peev txheej, thiab lwm yam.

4) Nws yog tsim tshwj xeeb tshaj yog rau kev thov ntawm nruab nrab chocolate thiab khoom qab zib Hoobkas.

| Qhov siab tshaj plaws (L): | 1000L |

| Sib tsoo Fineness (micron): | 20 ~ 25 |

| Main Axle Rotating Ceev (rpm): | 35 |

| Lub sijhawm sib tsoo (h): | 16-22 : kuv |

| Main lub cev muaj zog (kw): | 18.5 Nws |

| Hluav taws xob cua sov (kw): | 2 * 2 |

| Qhov hnyav (kg): | 3 050 |

| Sab nraud qhov ntev (mm): | 2627 * 1280 * 1520 |

Chocolate tuav lub tank

Siv:

Lub thawv ntim khoom qab zib yog cov khoom siv tsim nyog hauv cov kab ntau lawm chocolate.Nws hnav ob lub tsho sov-dej uas siv rau qhov kub thiab txias ntawm cov av nplaum chocolate paste.Yog li ntawd kom ua tau raws li qhov kev thov ntawm cov khoom siv chocolate thiab thov kev tsim khoom tas li.

Lub tank chocolate no muaj kev ua haujlwm ntawm qhov kub thiab txias, nce thiab khaws cia.

Dhau li ntawm nws muaj lub luag haujlwm ntawm degasification, desmelling, lub cev qhuav dej thiab tiv thaiv cov qhob noom xim kasfes los ntawm kev sib cais ntawm cov roj thiab roj thiab lwm yam.

| Qauv: | JY 1000 |

| Muaj peev xwm tshaj plaws | 1000 kg |

| Lub cev muaj zog: | 2.2 kwm |

| Stirring Rotational Ceev: | 24rpm ua |

| Whisk Rotational Direction: | Clockwise (Saib los ntawm saum toj no) |

| Hluav taws xob cua sov: | 4 kwv |

| Tank Interlayer Dej Kub: | 55 ° C (Sov-up kub ntawm chocolate loj) |

| Net nyhav: | 1000 kg |

| Sab nraud dimension: | 1220 * (qhov siab) 1850mm |

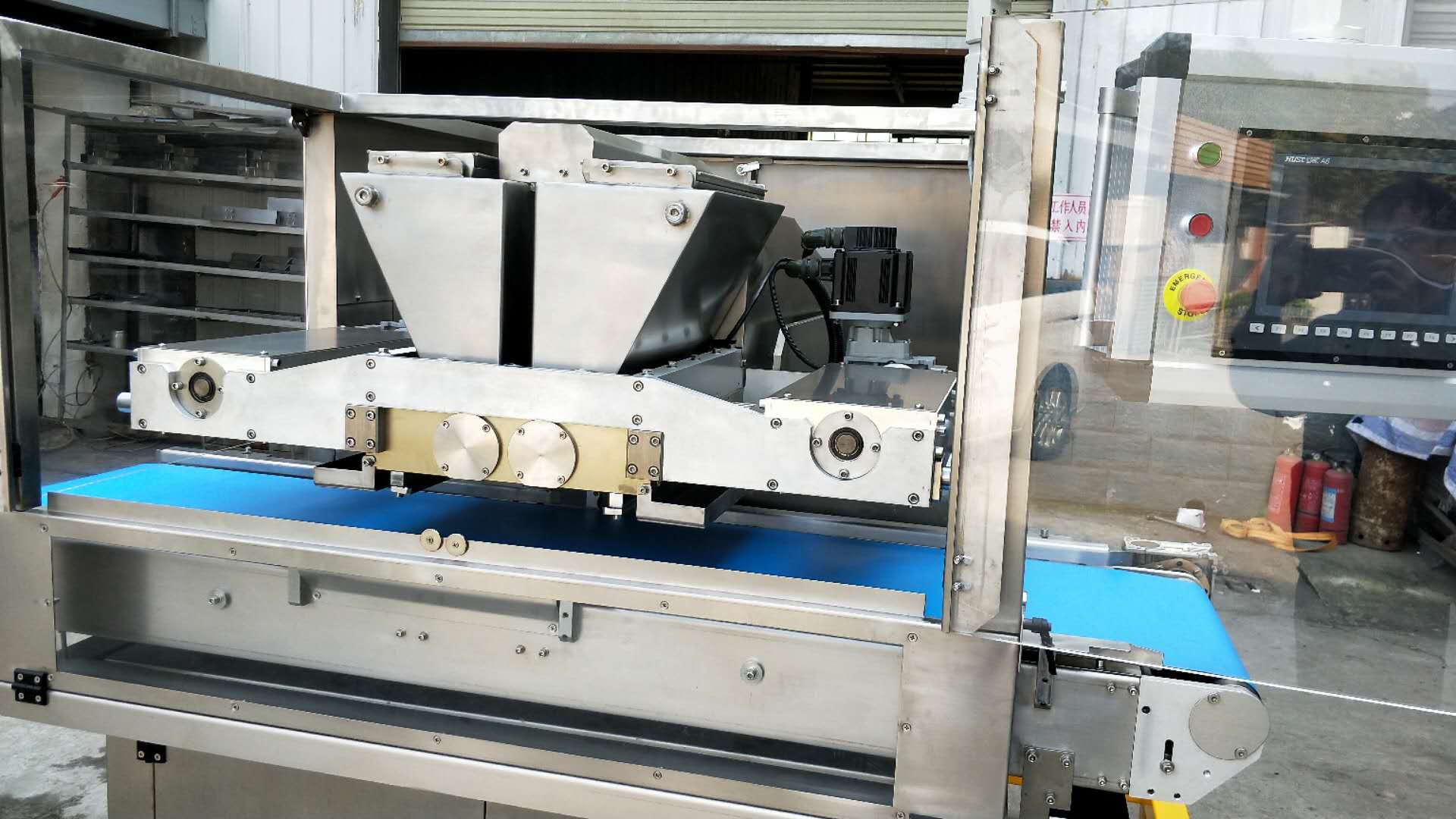

Chocolate depositing tshuab:

Siv:

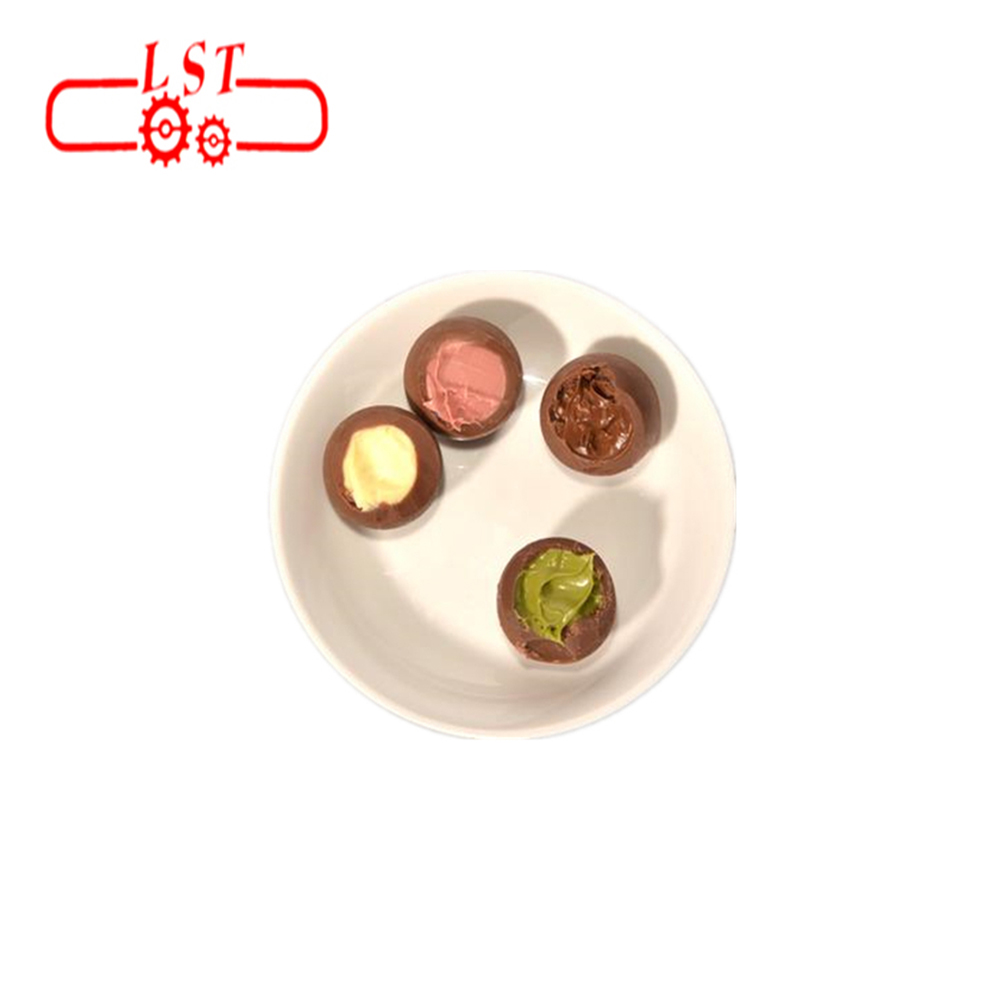

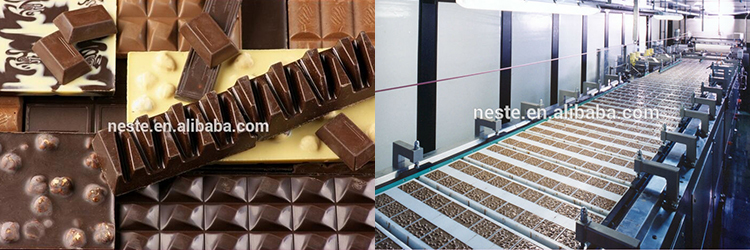

1) Qhov no chocolate depositing kab tuaj yeem tsim cov qhob noom xim kasfes dawb huv, nruab nrab sau cov qhob noom xim kasfes, ob xim qhob noom xim kasfes, txiv ntseej tov chocolate nrog txiv ntseej tov tshuab.Chocolate tuaj yeem yog cov qhob noom xim kasfes thiab chocolate tiag tiag.

2) Cov khoom tuaj yeem tsim nrog biscuits lossis wafers yooj yim los ntawm kev txhim kho cov khoom noj khoom haus biscuit.

3). Chocolate depositing kab tuaj yeem ua tiav tsis siv neeg pub pwm, ci pwm, tso nyiaj, vibrating pwm, txias, de-moulding, conveying npliag pwm rau lub voj voog AUTOMATICALLY thiab ntau npaum li cas yog txhua yam.

4) Cov kab ntawv tso nyiaj no muaj txiaj ntsig zoo ntawm cov khoom lag luam siab, kev noj kom raug, du nto ntawm chocolate thiab lwm yam.

| Muaj peev xwm ntau lawm: | 800-2500kg / ua haujlwm |

| Lub sijhawm tso nyiaj: | 20-25 zaug / feeb |

| Dosage system: | txhua yam |

| Mechanical vibrating zaus: | 200-1000 zaug / feeb. |

| Pwm vibrating amplitude: | 0-3mm, adjustable |

| Lub sijhawm txias: | 18-30 feeb |

| Qhov kub thiab txias: | 5-10 ° C |

| Cooling qhov ntev: | 8.2m * 8 Txheej |

| Lub sij hawm ntawm ci pwm: | 20-36 vib nas this |

| Kub ntawm ci pwm: | 35-40 ° C |

| Length ntawm ci pwm: | 1,4m ua |

| Lub tub yees muaj peev xwm: | 20000 - 25000 kcal / h (10 HP COPERLAND) |

| Qhov chaw evaporator: | 80 m² os |

| Qhov ntau ntawm cov pwm: | 300 pieces |

| Dimension ntawm moulds: | Standard 275 × 175 × 30mm |

| Tag nrho lub zog ntawm lub tshuab: | 17.4 kwm |

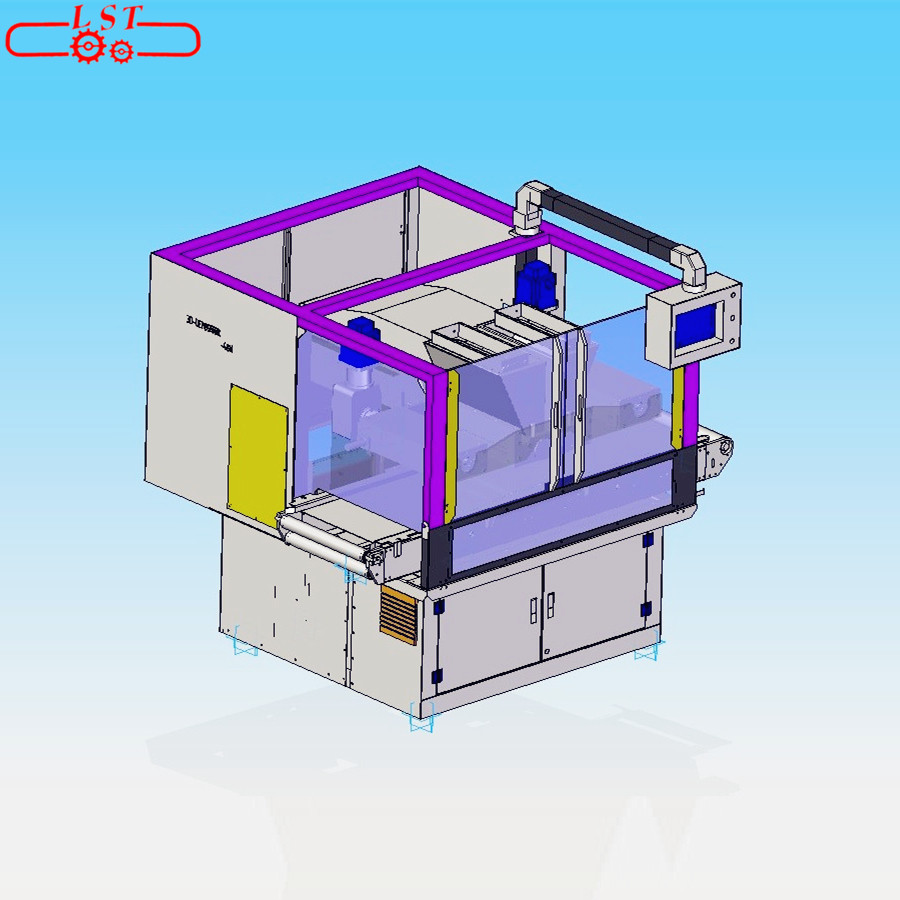

| Qhov Loj: | 16000 × 1000 × 1800 (L × W × H, hli) |

| Qhov hnyav ntawm lub tshuab: | 3500kg ib |

Yam ntxwv:

- PLC tswj, tsis siv neeg zaus tswj

- txiv neej-tshuab kov interface txhawm rau txheeb xyuas cov qib ntawm cov kua thiab cov khoom siv.Kev tiv thaiv overload rau lub tswb thaum muaj ib yam dab tsi tsis ncaj ncees lawm, thiab qhia nws ntawm lub vijtsam kov

- programming cia cov khoom hloov cov xim chocolate thiab cov khoom txhua 15 feeb.Ntau ruaj khov thaum khiav nrog cov tshuaj

- cais cua sov thiab tswj qhov system.Lub tshuab cua sov ua kom cov qhob noom xim kasfes nyob rau hauv qhov kub thiab txias thaum lub kaw lus tswj tau raug kaw, yog li kev pabcuam lub neej ntawm kev tswj kav ntev dua.

- nws tuaj yeem sib tov chocolate, txiv ntseej butter, txiv hmab txiv ntoo, lossis cereal nrog lwm cov khoom noj;cov khoom loafs muaj ntau yam thiab tuaj yeem kho tau

- nruab nrog 2 siab precision cam rotor twj tso kua mis kom sib tov cov khoom tsis tu ncua.Lub batching system thiab lub siab precision cam rotor twj tuaj yeem ua kom ruaj khov ntawm cov qhob noom xim kasfes thaum tsim khoom.

- Thaum lub sij hawm tsim khoom, cov khoom sib xyaw tuaj yeem kuaj pom los ntawm lub sensor, thiab ntxiv los ntawm cov transducer.Tag nrho cov txheej txheem tsim khoom yog tswj los ntawm lub sensor, thiab tsis tas yuav tsum nres.

- ua los ntawm cov hlau tsis muaj steel, thiab sib phim nrog cov khoom siv tshwj xeeb xws li cov hlau nplaum tsis muaj lub tog raj kheej, uas tuaj yeem ua tau raws li cov khoom noj huv huv.

- saws nrog cov cuab yeej cuab tam, peb txhim kho peb cov cav tov raws li cov kev pab cuam tom qab thiab cov ntawv xeem.Los ntawm cov neeg siv khoom xav tau, peb ntxiv lwm txheej ntawm cov khoom siv thauj khoom thiab cov qhob noom xim kasfes sib sau ua ke kom muaj ntau haiv neeg ntawm peb cov khoom

- tag nrho cov kab ntau lawm suav nrog: pwm, sib tov thiab tsim chav tsev, chav txias txias, chav ntim khoom

- pob kws pwm clamping ntaus ntawv tuaj yeem muab ntxiv raws li cov neeg siv khoom xav tau

technical nta:

Muaj peev xwm ntau lawm: 2000-6000KG / ua haujlwm

Tag nrho cov hwj chim: 27KW

huab cua siab: 0.6 Mpa

Zuag qhia tag nrho qhov ntev: 18500 × 1210 × 1800mm

pwm qhov ntev: 400 × 300 × 30mm (cov pwm thiab cov duab ntawm cov khoom tuaj yeem kho tau)

pwm tso zis: 10-16pcs / min

Nws yog qhov zoo los tsim cov qhob noom xim kasfes dawb huv, qhov chaw puv, ob lub xim chocolate thiab crispy mov chocolate, nrog rau qhov tseeb pouring tus nqi thiab ua haujlwm yooj yim.

1. Kev Them Nyiaj: T / T ua ntej.40% tso nyiaj, 60% tawm tsam kev lees paub los ntawm cov neeg siv khoom

2. nruj me ntsis nrog kev xeem ua tiav thiab kev kho kom zoo raws li cov neeg siv khoom xav tau ua ntej xa khoom xa tuaj.

3. Customization yog muaj.

5. Dab tsi yog cov ntaub ntawv kuv yuav tsum qhia rau koj paub yog tias kuv xav tau cov lus hais tag nrho?

Hnab hom, qhov loj me, qhov hnyav ntawm cov khoom, hom khoom, thickness, luam ntawv, xim, kom muaj nuj nqis

6. Thaum peb tsim peb tus kheej artwork tsim, hom hom twg muaj rau koj?

Hom ntawv nrov: AI, JPEG, CDR, PSD, TIF

7. Cov ntaub ntawv ntoo ntim nrog lub tshuab thiab lus Askiv manule

8. Transformer yog muab

9. Cov ntaub ntawv qhia ua lus Askiv tau muab

10. Lub tshuab yog stainless hlau

11. Nyob rau hauv txoj kab ntawm exporting packing khoom