chocolate forming ntau lawm tshuab Couverture Pure Chocolates ua khoom

- Siv tau Industries:

- Khoom noj khoom haus & dej haus Factory

- Hom Lub Npe:

- LST

- Qhov Chaw Keeb Kwm:

- Sichuan, Suav teb

- Voltage:

- 330/380V

- Lub zog (W):

- 27 kwv

- Qhov Loj (L * W * H):

- 18500 * 1210 * 2500mm

- Qhov hnyav:

- 6500kg ib

- Ntawv pov thawj:

- CE ISO

- Warranty:

- 1 xyoo

- Kev Pabcuam Tomqab Muag Khoom Muab:

- Field installation, commissioning thiab kev cob qhia, Engineers muaj rau kev pab cuam machinery txawv teb chaws

- Daim ntawv thov teb:

- Khoom noj txom ncauj Hoobkas

- Machinery Function:

- tso nyiaj

- Qhov xwm txheej:

- Tshiab

- Daim ntawv thov:

- Chocolate

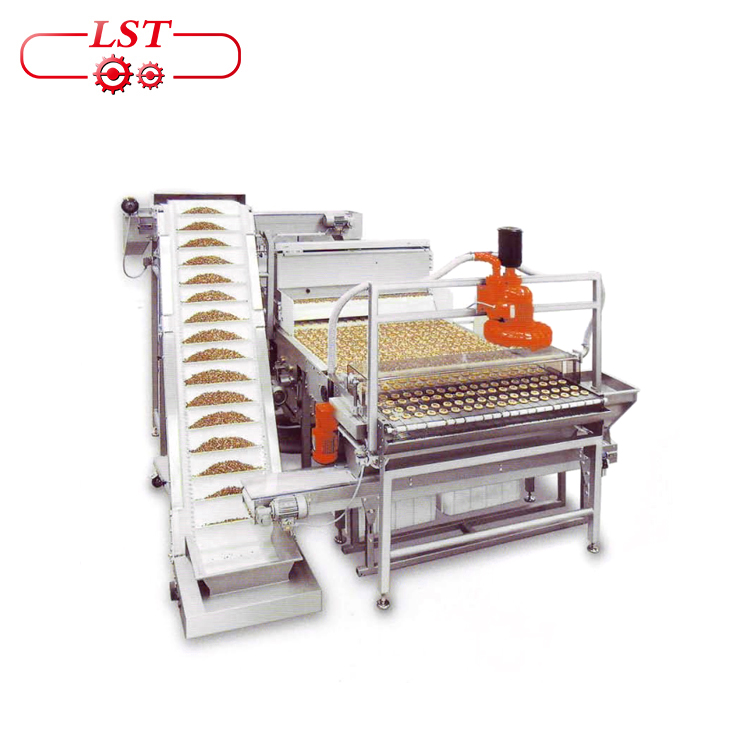

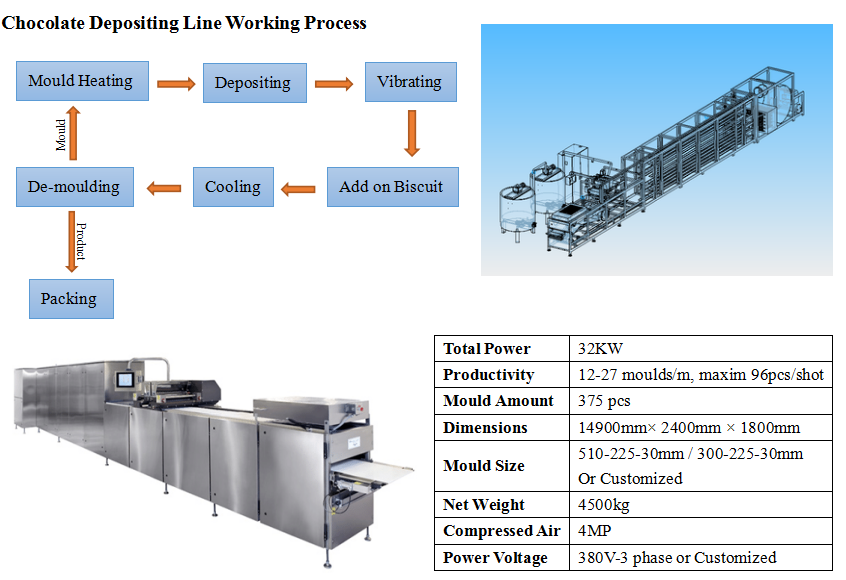

Qhov Chocolate depositing kab no yog ib lub tshuab ua haujlwm siab puv tshuab chocolate rau chocolate molding.Cov txheej txheem tsim muaj xws li pwm cua sov, chocolate depositing, pwm vibrating, pwm conveying, txias thiab demolding.Cov kab no tau siv dav hauv kev tsim cov khoom qab zib dawb huv, chaw ntim cov qhob noom xim kasfes, ob-xim chocolate, particle mix chocolate, biscuit chocolate, thiab lwm yam.

MainFnoj& Aqhov zoo

1.Tag nrho tsis siv neeg PLC tswj, ruaj khov thiab txhim khu kev qha.Servo system tsis tsuas yog txo tus nqi txij nkawm thiab kev sib kis rau cov khoom, tab sis kuj paub qhov chaw ruaj khov thiab loj dua.

2.Lub Beckhoff Chaw Taws Teeb Tswj los ntawm lub teb chaws Yelemeespab kom peb hloov kho qhov system tsis, kuaj mob & daws teeb meem ntawm kab, uas tsis yog yooj yim thiab ceev, tab sis kuj txuag nqi.

3.Nws muaj ntau yam khoom siv ntxiv tuaj yeem txuas rau cov kab ntau lawm, xws li Auto Biscuits Feeder, Auto Wafer Feeder, Auto Sprinkler, thiab lwm yam.Cov neeg siv khoom tuaj yeem xaiv cov khoom siv ntxiv no kom haum thiab ntxiv lossis hloov cov khoom siv ntxiv rau cov khoom tshiab thaum twg xav tau.

4.Qhov siab configuration ntau lawm kab tuaj yeem ua ke los ntawm txhua yam ntawm cov khoom, thiab cov khoom no tuaj yeem sib cais thiab rov ua dua nrog qee qhov chaw los ua lwm cov kab ntau lawm rau cov khoom sib txawv.

5.Muaj ib tus neeg tso nyiaj, ob tus neeg tso nyiaj lossis ntau dua kom tau raws li qhov xav tau ntawm cov khoom sib txawv.Cov txheej txheem tshwj xeeb ntawm cov khoom siv tso nyiaj ua rau kev teeb tsa, tshem tawm thiab hloov ntawm tus neeg tso nyiaj EASY & FAST.Nws tsuas yog siv sijhawm luv luv los ntxuav tus neeg tso nyiaj lossis hloov mus rau lwm tus tso nyiaj.

6.Tau tsim cov khoom sib txawv ntawm cov khoom qab zib, koj tsuas yog yuav tsum hloov tus neeg tso nyiaj lossis cov khoom qab zib

syrup faib phaj uas siv nrog tus neeg tso nyiaj.

7.Lub mobile depositor enables lub mobilepwm-ua raws li kev tso nyiaj ua haujlwm, uas ua rau muaj txiaj ntsig zoo ntawm cov kab ntau lawm los ntawm 20%.

8.Nrog rau cov ntaub ntawv yas-txoj kev tiv thaiv, cov saw yuav tsis sib cuag nrog cov kua nplaum uas nchuav, uas ua tau raws li tag nrho cov khoom noj huv huv.

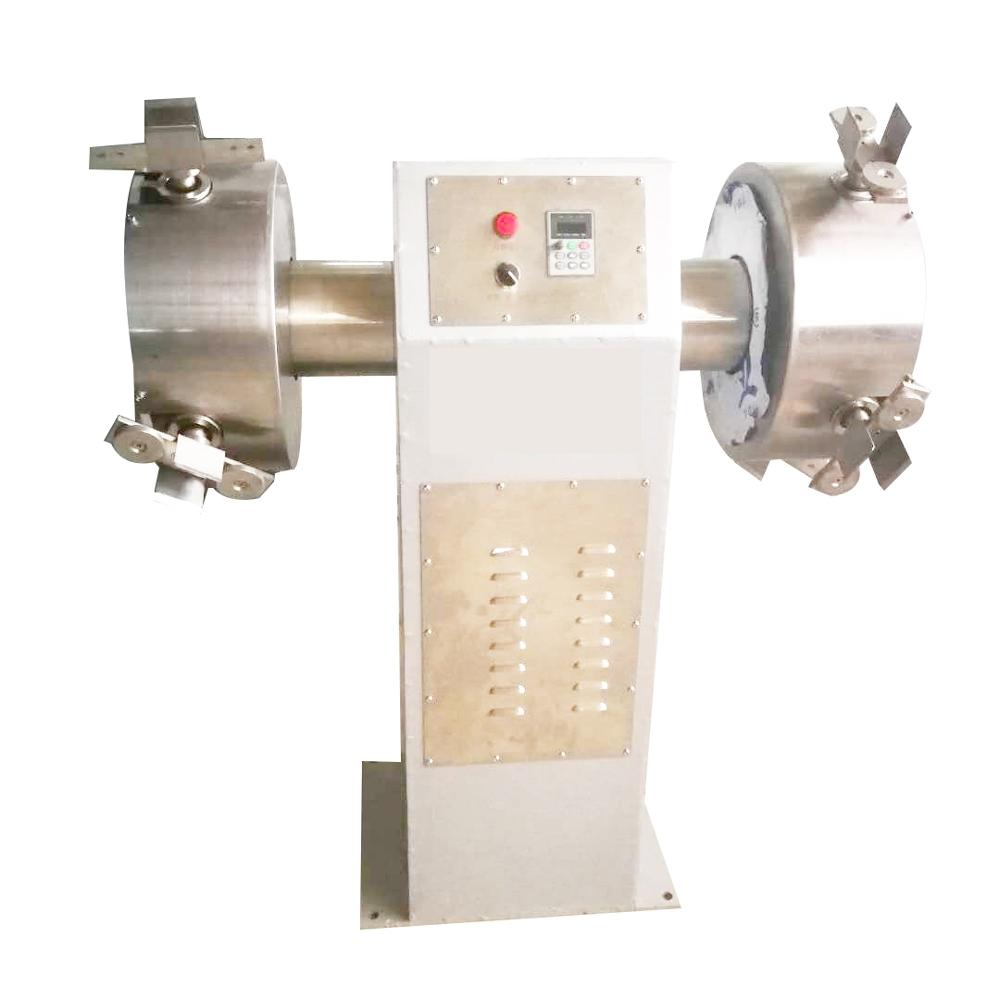

Muaj ntau omuajadd-on dcov evice, xws li pib pwm loader,sprinkler, biscuit feeder, Conche,tempering tshuab, decorating tshuab thiab ntau yam ntxiv. Koj tuaj yeem ntxiv qhov twg koj xav tau los ua kom nws ua tiav cov kab ntau lawm thiab tsim cov khoom sib txawv.

tshuab molding

Daim ntawv thov:

1.Cov kab molding yog rau chocolate deposit forming.

2.Cov txheej txheem tag nrho yogtag nrho tsis siv neegnrog rau kev tso nyiaj, pwm phaj vibrating, txias, demoulding, conveying thiab phaj cua sov.

3. Koj tuaj yeem xaiv ib lub taub hau semi-automatic, ob lub taub hau lossis peb lub taub hau rau molding kab rau cov khoom sib txawv.

4.Cov kab no yog tsim rauntshiab chocolate, nruab nrab puv chocolate, ob xim chocolate, plaub xim chocolate, thiab amber los yog agate chocolate.

LSTChocolate Enrobing Kab nrog Txias Qhov

Txoj kab enrobing yog coated chocolate rau ntau yam khoom noj xws li biscuit, wafers, qe yob, ncuav mog qab zib thiab khoom noj txom ncauj thiab lwm yam.

Lub qhov dej txias thiab qee cov khoom siv tshwj xeeb yog xaiv tau.

1: Khoom noj khoom haus: kom yooj yim rau kev pub mis ntawm biscuits lossis wafers rau enrobing hlau mesh.

2: Granular sprinkler: rau sprinkle sesame lossis txiv laum huab xeeb granular ntawm cov khoom enrobing.(Ntxiv-on ntaus ntawv)

3: Kho kom zoo nkauj: txhawm rau kho cov zigzags lossis kab txaij ntawm cov xim sib txawv ntawm cov khoom siv enrobing.(Ntxiv cov khoom siv)

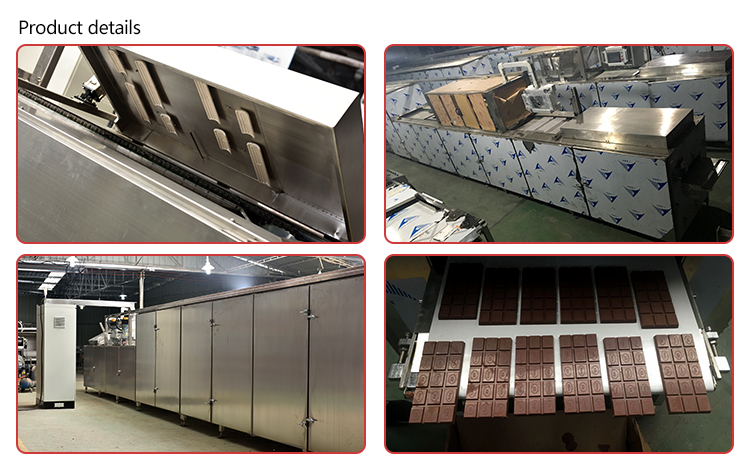

CooLing Tunnel

Cua txias tunnels yog universally siv rau cov khoom txias tom qab molding.Xws li puvcandy, khoom qab zib nyuaj, taffy khoom qab zib, chocolate thiabntaulwm yam khoom qab zib.Tom qab xa mus rau qhov txias txias, cov khoom yuav txias los ntawm cov co tshwj xeeboua pa.Cov nyhuv txias yog ruaj khov thiab tag nrho cov txheej txheem huv si.Import compressor los ntawm teb chaws USA thiab zaus converterzoo heevtxhim kho stability thiabdurabilityntawm no ntaus ntawv.

Nta thiab Qhov Zoo:

1.Qhov qhov txias txias yog nruab nrog 2 txheej ntawm 5P tub yees tshuab.Direct kov txias rau sab hauv qab thiab indirect sab saum toj txias tsim.

2.Tag nrho cov hlau stainless thiab cov khoom noj khoom haus qib conveyor siv uas ua raws li kev noj qab haus huv thiab kev nyab xeeb tus qauv.

3.Ob theem lossis ntau theem ntawm kev ua kom txias, xws li cua txias txias thiab cov tub yees txias txias, thiab lwm yam.Lub tshuab cua txias ntau theem ua rau nws txuag hluav taws xob, cua txias ceev, ua haujlwm yooj yim, thiab lwm yam.

4.Tunnel npog siv lub tswv yim tsim tshiab kawg, tag nrho npog thiab kaw tsim kom tsis txhob muaj zog poob.

5.Lub hau npog tuaj yeem qhib lossis tshem tawm yooj yim, tsis muaj cov cuab yeej xav tau, yooj yim rau kev ntxuav.