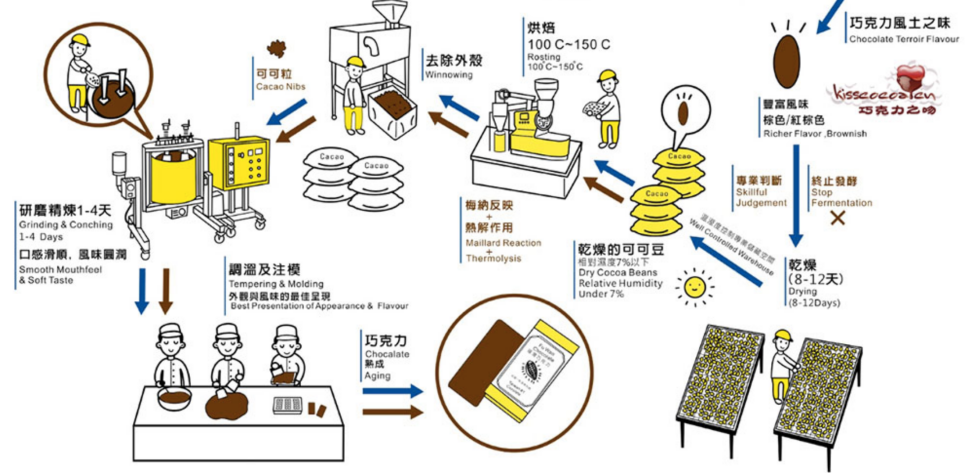

Hoʻouna ʻia nā pīni koko i hoʻomaloʻo ʻia i ka lā i ka hale hana, e hoʻomaka ana i kāna huakaʻi hoʻololi ... Mai nā pīni ʻawaʻawa a hiki i ke kokoleka ʻono, pono ke ʻano o nā kaʻina hana.Wahi a ke kaʻina hana, hiki ke hoʻokaʻawale ʻia i 3 mau kaʻina, pulping Pressing, wili maikaʻi a me ka hoʻomaʻemaʻe, hoʻoponopono ʻana i ka mahana a me ka hoʻoheheʻe ʻana.

I kēia manawa, mālama mau nā wahi he nui o ka honua i ke ʻano kumu o ka hoʻomaʻamaʻa ʻana i nā pī koko, akā i hana lima ʻia mai ka pī koko a hiki i ke kokoleka, e ʻono ka ʻono.No laila ke kamaʻilio nui nei kēia ʻatikalapehea e hoʻohana ai i nā mīkini e hoʻopau i kēia ʻano hana

1. ʻO ka wili ʻana a Phoʻopaneʻe

Hoʻopiʻi ʻia nā pīni koko a kaomi ʻia no ka loaʻa ʻana o ka wai koko, ka pata koko, a me ka pauka koko.

Ma mua o ka pulupulu ʻana a me ke kaomi ʻana, pono ia e hele ma ke kaʻina o ke koho ʻana i ka pī, ka holoi ʻana i ka pī, ka ʻala ʻana, ka winnowing a me ka ʻoki ʻana.ʻO ke koho ʻana i ka pīni, e like me ka inoa e hōʻike ai, ʻo ia ka nānā ʻana i nā pī koko pono ʻole a i ʻole nā pōʻino.E holoi i ka pī, holoi a maloʻo.A laila, hoʻomaka e kālua, wili, ʻohi, a wili maikaʻi no ka loaʻa ʻana o ka wai koko, a maʻalili ka nui o ka wai koko e loaʻa ai ka nui o ka wai koko.Paʻi ʻia ka waiʻona koko ma o ka mīkini ʻaila e unuhi i ka pata koko.ʻO ka pauka koko ka keke koko i koe ma hope o ka ʻomi ʻia ʻana o ka wai koko no ka wehe ʻana i ka ʻaila, a laila ʻoki ʻia, lepo, a kānana ʻia a loaʻa ka pauda ʻulaʻula ʻulaʻula.

1.1 Baking - Mīkini Roa Koko

Hoʻomoʻa ʻia nā pīni koko ma nā wela kiʻekiʻe ma waena o 100 a 120°C.He 30 mau minuke ke kaʻina holoʻokoʻa e hōʻoia i ka hoʻopuka ʻana o kēlā me kēia pīni koko i kahi ʻono koko momona ma hope o ka ʻohi ʻana.

1.2 Winnowing a me ka ʻohi ʻana - Koko Cracking & Winnowing Machine

Ma hope o ke kālua ʻana, ʻeleʻele ke kala o ka koko, kokoke i ke kala ʻeleʻele o ke kokoleka ponoʻī.Maʻalili koke nā pīni koko, a pono e wehe ʻia nā ʻili lahilahi e lilo i mea palupalu i ka wā e kālua ʻia ai, e pono ai e puhi i nā ʻili.ʻO nā nibs, ka mea hiki ke hoʻohana ʻia o ka pī koko, waiho ʻia a ʻeli ʻia a lilo i nibs.Kapa ʻia kēia ʻanuʻu i ka winnowing a me ka ʻohi ʻana, a he nui nā ʻano hana like ʻole, ʻo ka maʻalahi o ia mea ʻo ka hoʻopau loa ʻana i ka ʻili me ka nalowale ʻole o ka piʻi honua.Inā he ʻili paʻakikī i hui pū ʻia me ke kokoleka, e lawe mai ia i kahi ʻono ʻole.

Hiki ke hana ʻia kēia kaʻina hana ma mua o ka ʻai ʻana.Pono e kālua ʻia nā pī a pau ma kahi o 400 ° C no 100 kekona, i maʻalahi nā pī koko e hoʻokahe i ka ʻili pi ma hope o kēia kaʻina hana.A laila, ʻoki ʻia a liʻiliʻi loa, wehe ʻia nā ʻili koko ma ke kaʻina hana, ma mua o ka ʻala ʻia.

I ka nui o nā hale hana, hana ʻia kēia kaʻina hana me ka "fan crusher", kahi mīkini nui e puhi ana i nā hulls.Hoʻohele ka mīkini i nā pī i loko o nā cones serrated i mea e haki ai lākou ma mua o ka haki ʻana.I ka wā o ke kaʻina hana, hoʻokaʻawale kekahi mau kānana mechanical i nā ʻāpana i nā ʻāpana like ʻole o ka nui aʻo ka puhi ʻana o nā mea pā i ka ʻili lahilahi o waho mai nā ʻāpana pulpy.

1.3 Ka wili maikai - Colloid Mill&Melanger

I loko o kahi hale hana kokoleka hou, hiki iā ʻoe ke koho e hoʻohana i ka wili colloid a i ʻole ka wili pōhaku e wili ai i nā pī i ʻoki ʻia i loko o kahi slurry.

ʻO ke kumu hana o ka wili colloid ʻo ka ʻāhi, wili, a me ka wikiwiki wikiwiki.Hana ʻia ke kaʻina wili i ka neʻe pili ʻana ma waena o ʻelua mau niho, e kaʻa ana kekahi i ka wikiwiki kiʻekiʻe a ʻo kekahi e kū mau.Ma waho aʻe o ka haʻalulu kiʻekiʻe a me ka wikiwiki o ka eddy current, ʻo ka mea ma waena o nā niho e hoʻopili ʻia i ka ʻoki ikaika a me ka ʻaʻahu.ʻO ka mea e like me ka pulverized, dispersed a emulsified.

Hoʻohana ʻia nā wili pōhaku ʻelua no ka wili mau ʻana.Hoʻokuʻu mālie ʻia ka pata koko i loko o nā nibs koko ma hope o ka hoʻomaloʻo ʻia ʻana i loko o ka wā lōʻihi o ka ʻōwili ʻole ʻana, e hana ana i kahi slurry mānoanoa, e hoʻopuʻu ʻia i loko o nā puʻupuʻu ma hope o ka hoʻoilo.

ʻO kaʻoiaʻiʻo, i ka wā e hiki mai ai i ka pae o ka wili maikaʻi a me ka hoʻomaʻemaʻe ʻana, ʻaʻole ia he mea ʻē aʻe ma mua o ka hoʻololi ʻana i kahi "wili blender" ʻoi aku ka maikaʻi no ka wili mau ʻana.

Hana ʻia ka pata koko ma ke ʻano he lubricant no ka mea ʻo ke kō a me ka pauka koko i ʻeli ʻia i mau ʻāpana liʻiliʻi.Hiki i ka waha kanaka ke ʻono i nā ʻāpana ʻoi aku ka nui ma mua o 20 microns.No ka mea makemake nā kānaka a pau e leʻaleʻa i ke kokoleka maikaʻi loa a waiwai hoʻi, pono mākou e hōʻoia i ka liʻiliʻi o nā ʻāpana waiwai a pau o ke kokoleka ma mua o kēia nui.ʻO ia hoʻi, pono e hoʻoheheʻe ʻia ka pauka koko i lalo o 20 microns, ʻo ia ka hana hou o ka hoʻomaʻemaʻe a me ka hoʻomaʻemaʻe ʻana, no laila pono e hoʻomau i ka wili ʻana no ka manawa lōʻihi.

Melanger

ʻO Colloid Mill

1.4 Wehe-Aila Pa'i Mīkini & Pahu Mīkini Mīkini

ʻO ka pata koko a me ka pauka koko ka wai koko a i ʻole ka wai nui i hana ʻia ma hope o ka pulping, pono e unuhi ʻia ma ke kaomi ʻana.E kaomi i ka waiʻona koko e hoʻokaʻawale i ka pata koko, nona ka momona o 100%, a laila wili i ke koena keke pīni e hana i ka pauka koko, me ka momona o 10-22%.

E kau i ka wai koko i loko o ka mīkini aila ʻakomi, a e hoʻokiʻekiʻe ʻia e ka piston o ka pahu aila, a kahe ka aila mai ka puka kuʻi, a komo i ka pahu aila ma o ka pā aila e mālama ai i ka aila.

Nui nā ʻāpana o nā pahi hoʻoneʻe (a i ʻole prisms a i ʻole nā poʻo hāmare) i ka huila kaʻa i loko o ka hale wili, a me kahi pūʻulu o nā pahi paʻa i ke apo.I ka wā o ka ʻoki ʻana ma waena o ka pahi hoʻoneʻe a me ka pahi paʻa, ua ʻoki ʻia ka mea.I ka manawa like, hoʻopuka ke keʻena kuʻi i ka ea, kahi e hoʻokuʻu ai i ka wela me ka huahana i hoʻopau ʻia mai ka pale.

2. Mīkini Hoʻomaʻemaʻe-kokoleka

I ka ʻimi ʻana i ke kokoleka ʻeleʻele maʻemaʻe, ʻaʻole pono ʻoe e hoʻohui i nā mea kōkua, ʻo ke kō nui loa, akā ʻo kēia ka koho o ka mea liʻiliʻi.Ma waho aʻe o ka nui koko, ka pata koko a me ka pauka koko, pono pū ka hana kokoleka kaulana i nā mea e like me ke kō, nā huahana dairy, lecithin, nā ʻono a me nā surfactants.Pono kēia i ka hoʻomaʻemaʻe a me ka hoʻomaʻemaʻe.ʻO ka wili a me ka hoʻomaʻemaʻe ʻana he hoʻomau i ka hana mua.ʻOiai ʻo ka maikaʻi o ka mea kokoleka ma hope o ka wili ʻana ua hiki i ke koi, ʻaʻole lawa ka lubricated a ʻaʻole ʻoluʻolu ka ʻono.ʻAʻole i hui pū ʻia nā mea like ʻole i kahi ʻono kūʻokoʻa.Aia kekahi mau ʻono maikaʻi ʻole, no laila pono e hoʻomaʻemaʻe hou aku.

Ua haku ʻia kēia ʻenehana e Rudolph Lindt (ka mea nāna i hoʻokumu iā Lindt 5 grams) i ka hopena o ke kenekulia 19.ʻO ke kumu i kapa ʻia ai ʻo "Conching" no ka mea, he pahu pōʻai pōʻai i hana ʻia e like me ka pūpū conch.Kapa ʻia ka conch (conche) mai ka Spanish "concha", ʻo ia hoʻi ka pūpū.Hoʻohuli pinepine ʻia ka wai kokoleka e ka roller no ka manawa lōʻihi i loko o ia pahu, hoʻokuʻi ʻia a ʻānai ʻia e loaʻa ai ka lubrication palupalu, ka ʻala ʻala a me ka ʻono ʻono kūʻokoʻa, ua kapa ʻia kēia kaʻina "wili a hoʻomaʻemaʻe"

I ka hoʻomaʻemaʻe ʻana, hiki ke hoʻohui ʻia nā mea kōkua like ʻole.

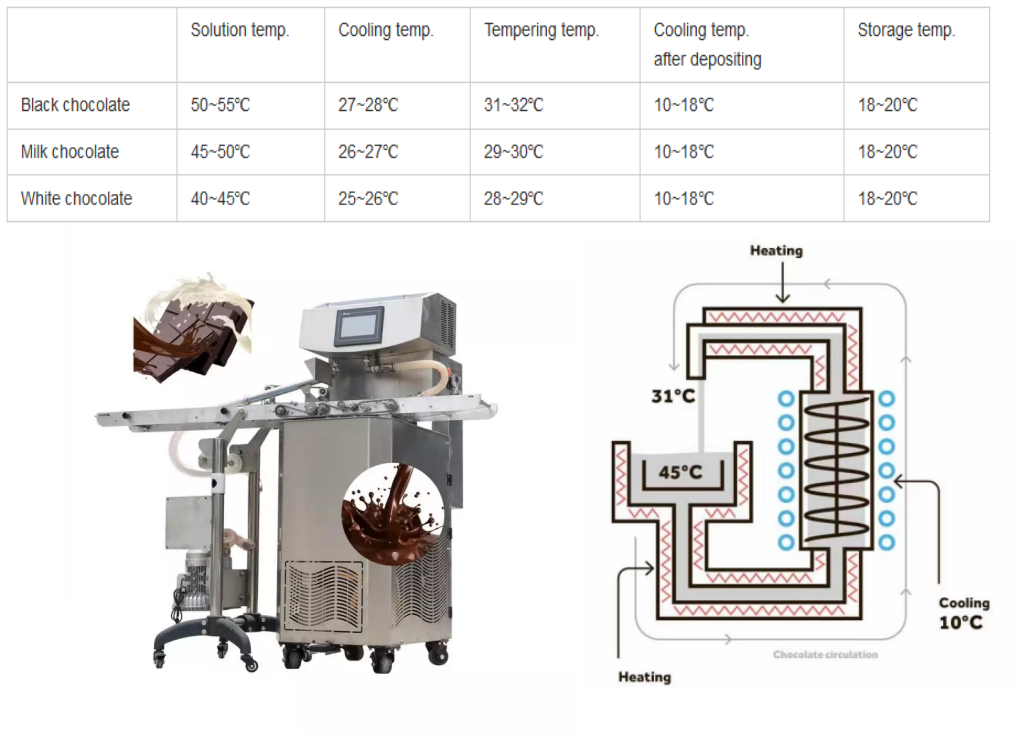

3. Temper & Moulds-Mīkini hoʻoheheʻe & Moulding

ʻO ka Tempering ka hana hope loa i ka hana ʻana a he hopena nui i ka ʻike kokoleka hope loa no nā mea kūʻai.Ua loaʻa paha iā ʻoe kahi kokoleka i ʻuʻuku a loaʻa kahi kiʻiʻoniʻoni keʻokeʻo opaque ma waho?ʻAʻole i hana maikaʻi ʻia ka hoʻomaʻamaʻa ʻana a i ʻole kekahi mea i hewa i nā mea ʻai.

No ka hiki ʻana i lalo o kēia nīnau, pono ʻoe e ʻike i kekahi mau mea e pili ana i ka pata koko.He 48%-57% ka nui o ka paona koko.ʻO ia ka mea e hoʻoheheʻe ʻole ai ke kokoleka ma ka lima (paʻa ma ka lumi wela) hiki ke hoʻoheheʻe wale ʻia i ka waha (hoʻomaka e heheʻe i ka wela o ke kino).ʻO ka hoʻokomo ʻana i kahi ʻāpana kokoleka ma kou alelo a manaʻo ʻoe e hehee mālie i kou waha kekahi o nā ʻano hoʻowalewale o ke kokoleka, a mahalo nui ia i ka pata koko.

ʻO ka pata koko he polymorphic, ʻo ia hoʻi, ma lalo o nā kūlana solidification like ʻole, hana ia i nā ʻano kristal like ʻole, hiki ke kūpaʻa a paʻa ʻole paha.Hoʻopili piha ʻia nā kristal paʻa a ʻoi aku ka nui o nā helu heheʻe ma mua o nā kristal paʻa ʻole.No laila, pono mākou e hoʻololi i ka mahana e hōʻoia i ka ʻano o ka pata koko a me ka pata koko e like me ke ʻano aniani paʻa loa, a laila hoʻomaʻalili pololei i mea e ʻulaʻula maikaʻi ai ke kokoleka a ʻaʻole e pua no ka manawa lōʻihi.ʻO ka maʻamau, ʻo ke ʻano o ka hoʻomaʻamaʻa ʻana i ka kokoleka e pili ana i kēia mau ʻanuʻu

1. E hoohehee loa i ke kokoleka

2. Hoʻolili i ke kiko wela crystallization

3. E hana i ka crystallization

4. E hoʻoheheʻe i nā kristal paʻa ʻole

Hiki ke hoʻoponopono lima ʻia ka mahana, akā pono e pololei ka mahana.ʻO ke koho ʻana i ka mīkini hoʻoheheʻe kokoleka e hoʻomalu pono ana i ka wela a hiki i kahi ʻokoʻa wela ma lalo o ± 0.2 hiki ke kōkua maikaʻi iā ʻoe.ʻAʻole kūlike ʻole ka hoʻoulu ʻana o nā kokoleka like ʻole:

I ka wā i hoʻomaʻamaʻa maikaʻi ʻia ai ka ʻuala kokoleka, pono e hana koke ʻia, a laila hoʻomaloʻo e hoʻoponopono i ka hale a hoʻololi iā ia i kahi kūlana paʻa paʻa.Hiki ke ninini ʻia me ka lima a i ʻole ka mīkini.ʻAʻole pololei ka ninini lima ʻana i loko o nā mole e like me ka ninini ʻana o ka mīkini, no laila pono e ʻoki ʻia ka ʻai keu.Ma hope o ka hoʻoluʻu ʻana, hiki ke hoʻoheheʻe ʻia i loko o kahi kokoleka nani.

Ka manawa hoʻouna: Nov-28-2022