Ana aika waken koko mai busasshen rana zuwa masana'anta, a hukumance ta fara tafiya ta canji ... Daga wake mai ɗaci zuwa cakulan mai daɗi, ana buƙatar jerin hanyoyin sarrafawa.Dangane da tsarin sarrafawa, ana iya raba shi kusan zuwa matakai 3, pulping Pressing, kyakkyawan niƙa da tacewa, daidaita yanayin zafi da gyare-gyare.

Yanzu, wurare da yawa a cikin duniya har yanzu suna kula da ainihin hanyar sarrafa ƙwayar koko ta wucin gadi, amma abin hannu daga wake koko zuwa cakulan, ɗanɗanon zai zama m.Don haka wannan labarin yafi magana akaiyadda ake amfani da injina don kammala wannan jerin sarrafawa

1. Nika da Pressing

Ana niƙa waken koko ana dannawa don samun giyar koko, man shanu, da garin koko.

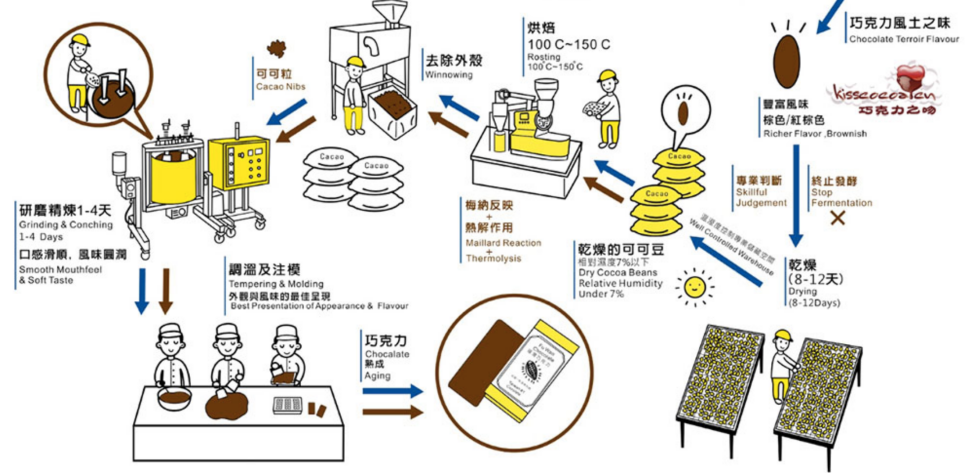

Kafin a latsawa da latsawa, dole ne ta bi tsarin zaɓin wake, wanke wake, gasawa, tatsa da murƙushewa.Zaɓin wake, kamar yadda sunan ke nunawa, shine don tantance waken koko da bai cancanta ba ko ɓarna.A wanke wake, kurkura da bushe.Daga nan sai a fara gasa, a daka, a daka, a nika sosai don samun giyar koko, sannan a sanyaya yawan barasar koko don samun ruwan barasa.Ana matse barasar koko ta hanyar matse mai don fitar da man koko.Foda koko shi ne kek ɗin koko da ke saura bayan an matse ruwan kokon a cire mai, sannan a niƙa, a niƙa, a toka don samun foda mai launin ruwan kasa.

1.1 Yin burodi - Injin Roaster Cocoa

Ana gasa waken koko a yanayin zafi tsakanin 100 zuwa 120 ° C.Gabaɗayan aikin yana ɗaukar mintuna 30 don tabbatar da cewa kowane ɗan wake yana fitar da ɗanɗanon koko bayan an gasa shi.

1.2 Cin Gindi da Murkushewa - Injin Cracking Cocoa & Winnowing Machine

Bayan an gasa, wake na koko ya zama duhu a launi, yana kusa da launin ruwan duhu na cakulan kanta.Waken koko ya yi sanyi da sauri, kuma siraran harsashi da suka yi rauni yayin gasa dole ne a cire su, suna buƙatar magoya baya su busa fatun.Nibs, ɓangaren da ake amfani da shi na koko, an bar su kuma a niƙa su cikin nibs.Wannan mataki shi ake kira winnowing da crushing, kuma akwai hanyoyi daban-daban, mafi wayo wanda shine kawar da fata gaba daya ba tare da rasa wake ba.Idan akwai fata mai taurin kai gauraye da cakulan, zai kawo wani ɗanɗano mai daɗi.

Hakanan za'a iya aiwatar da wannan tsari a matakin gasa kafin a gasa.Duk wake yana buƙatar a gasa shi a cikin yanayin zafin jiki na 400 ° C na tsawon daƙiƙa 100, saboda waken koko yana da sauƙin zubar da fatar wake bayan wannan tsari.Daga nan sai a nika shi cikin kananan hatsi, ana cire duk wani fatun koko a cikin aikin, kafin a gasa shi.

A mafi yawan masana'antu, ana yin wannan tsari ne da "fan crusher", wata babbar injin da ke hura tarkace.Injin yana wucewa da wake ta cikin mazugi masu ɗorewa domin ya karye maimakon murkushe su.A yayin aiwatar da aikin, jerin sieves na injina suna rarraba guntuwar zuwa ɓangarorin masu girma dabam yayin da magoya baya ke busa harsashi na bakin ciki daga ɓangarorin ɓarna.

1.3 Kyakkyawan niƙa - Colloid Mill & Melanger

A cikin masana'antar cakulan zamani, zaku iya zaɓar yin amfani da injin colloid ko injin dutse don niƙa dakakken wake a cikin slurry.

Ka'idar aiki na niƙa colloid ita ce shearing, niƙa, da motsawa mai sauri.Tsarin niƙa yana faruwa ne a cikin motsin dangi tsakanin hakora biyu, ɗayan yana jujjuya cikin babban gudu yayin da ɗayan ya kasance a tsaye.Bugu da ƙari ga ƙararrawar mita mai girma da kuma babban saurin eddy halin yanzu, kayan da ke tsakanin hakora kuma suna fuskantar karfi da lalacewa.Kayan zai zama daidai gwargwado, tarwatsawa da emulsified.

Masu niƙa na dutse suna amfani da granite rollers biyu don ci gaba da niƙa.Man shanun koko da ke cikin nibs na kokon shima ana fitar da shi sannu a hankali bayan an nisa shi sosai a cikin dogon lokaci ba a daina birgima ba, wanda ya zama slurry mai kauri, wanda ya taso ya zama dunkule bayan ya huce.

A gaskiya ma, idan aka zo mataki na nika mai kyau da tacewa, ba kome ba ne face canza zuwa "nika mai kyau" don ci gaba da nika.

Man shanu na koko yana aiki azaman mai mai kamar yadda sukari da foda koko ake niƙa cikin ƙananan barbashi.Bakin ɗan adam na iya ɗanɗano barbashi fiye da 20 microns.Tun da kowa yana son jin daɗin ɗanɗano mai santsi kuma mai wadataccen cakulan, dole ne mu tabbatar da cewa duk abubuwan da ke cikin cakulan sun fi wannan girman.Wato foda na koko dole ne a nika shi zuwa ƙasa da microns 20, wanda shine mataki na gaba na tacewa da tacewa, don haka yana buƙatar ci gaba da niƙa na tsawon lokaci.

Melanger

Colloid Mill

1.4 Injin Latsa Mai & Foda Nika Machine

Man shanu da koko da foda na koko suna ɗauke da ruwan koko ko ruwan da ake samarwa bayan ɗigon ruwa, wanda ake buƙatar cirewa ta hanyar dannawa.Sai ki matse barasar koko ki raba man kokon mai kitse 100% sai a nika sauran kek din wake a yi hodar koko, mai kitse na 10-22%.

A zuba ruwan koko a cikin injin man fetur ta atomatik, sai a dauke shi da piston na silinda mai, sannan man zai fita daga gibin naushin, sannan ya shiga cikin ganga mai ta cikin farantin mai don adana mai.

Akwai nau'ikan wukake masu motsi da yawa (ko prisms ko kan guduma) a cikin motar juyawa a cikin injin niƙa, da saitin ƙayyadaddun wukake a cikin kayan zobe.A lokacin da ake yankan karo tsakanin wuka mai motsi da wuka da aka kafa, an lalata kayan.A lokaci guda kuma, ɗakin murƙushewa yana haifar da iska, wanda ke fitar da zafi tare da samfurin da aka gama daga allon.

2. Refining-Chocolate Conching Machine

Don neman tsantsar cakulan cakulan, ba kwa buƙatar ƙara kowane kayan taimako, har ma da mafi ƙarancin sukari, amma wannan shine zaɓi na tsirarun bayan duk.Baya ga yawan koko, man shanu da kuma foda koko, shahararren cakulan kuma yana buƙatar sinadarai irin su sukari, kayan kiwo, lecithin, dadin dandano da abubuwan surfactants.Wannan yana buƙatar tacewa da tacewa.Nika da tacewa haƙiƙa ci gaba ne na tsarin da ya gabata.Kodayake ingancin kayan cakulan bayan niƙa ya kai ga abin da ake buƙata, ba a lubricated sosai ba kuma dandano bai gamsar ba.Har yanzu ba a haɗa abubuwa daban-daban ba zuwa wani dandano na musamman.Wani ɗanɗano marar daɗi har yanzu yana nan, don haka ana buƙatar ƙarin gyare-gyare.

Rudolph Lindt (wanda ya kafa Lindt 5 grams) ne ya kirkiro wannan fasaha a ƙarshen karni na 19.Dalilin da ya sa ake kiransa "Conching" shine saboda asalin tanki ne mai da'ira mai siffa kamar harsashi.Ana kiran sunan conche (conche) daga Spanish "concha", wanda ke nufin harsashi.Ana sake jujjuya kayan ruwan cakulan da abin nadi na dogon lokaci a cikin irin wannan tanki, turawa da gogewa don samun lubricant mai laushi, ƙamshi mai ƙanshi da ɗanɗano na musamman, ana kiran wannan tsari "niƙa da sakewa"

Yayin tsaftacewa, ana iya ƙara kayan taimako daban-daban.

3.Temper&Moulds-Tempering Machine & Molding

Tempering shine mataki na ƙarshe na samarwa kuma yana da babban tasiri akan ƙwarewar cakulan ƙarshe ga masu amfani.Shin kun taɓa samun cakulan da ke da murƙushewa kuma yana da farin fim mara kyau a waje?Ko dai ba'a yi daidai ba ko kuma wani abu ba daidai ba ne tare da kayan aikin.

Don zuwa kasan wannan tambayar, kuna buƙatar sanin wasu abubuwa game da man koko.Man shanu na koko yana da kashi 48% -57% na nauyin wake.Abu ne da ke sanya cakulan da ba a narkewa a hannu (mai ƙarfi a zafin jiki) kawai mai narkewa a cikin baki (fara narke a zafin jiki).Sanya cakulan cakulan a harshenka da jin shi a hankali yana narkewa a cikin bakinka yana daga cikin mafi yawan halayen cakulan, kuma duk godiya ne ga man shanu na koko.

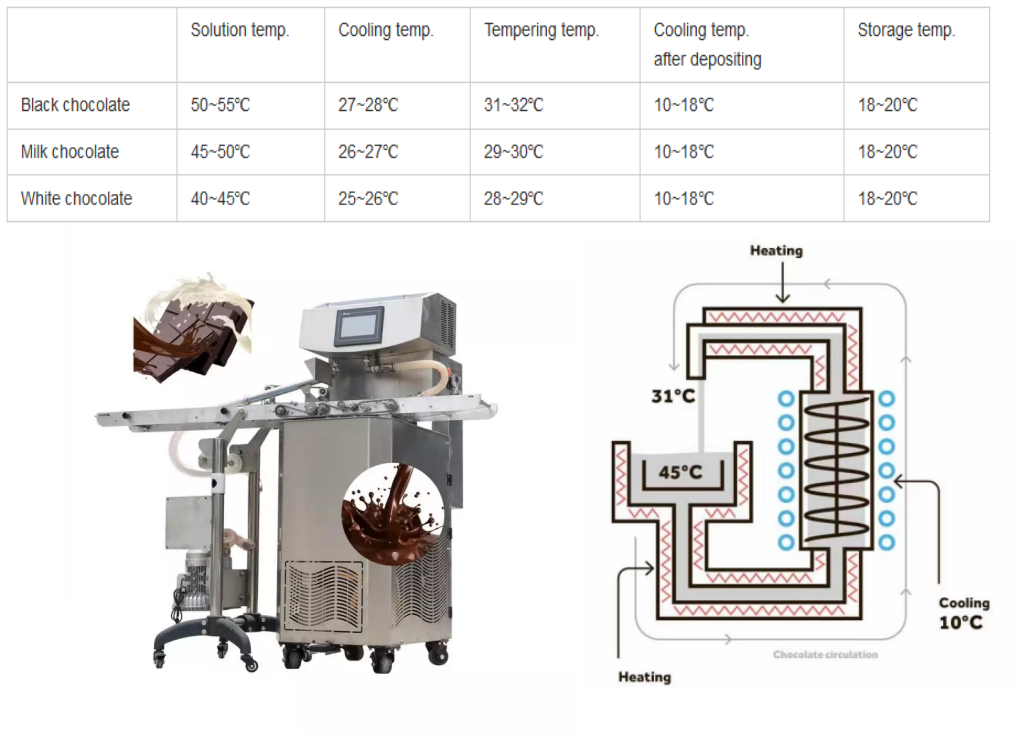

Man shanu na koko shine polymorphic, wanda ke nufin cewa, a ƙarƙashin yanayi daban-daban na ƙarfafawa, yana samar da nau'in lu'ulu'u daban-daban, wanda zai iya zama ko dai barga ko maras tabbas.Lu'ulu'u masu tsayayye an cika su kuma suna da maki narke fiye da lu'ulu'u marasa ƙarfi.Don haka, dole ne mu daidaita yanayin zafi don tabbatar da cewa man shanu na koko da man shanu-kamar sun zama sigar mafi tsayin crystal, sa'an nan kuma sanyaya shi daidai yadda cakulan ya sami haske mai kyau kuma baya yin fure na dogon lokaci.Yawancin lokaci hanyar tempering cakulan ya haɗa da matakai masu zuwa

1. Narke cakulan gaba daya

2. Cool zuwa wurin zafin jiki na crystallization

3. Samar da crystallization

4. Narkar da lu'ulu'u marasa ƙarfi

Za a iya daidaita zafin jiki da hannu, amma zafin jiki dole ne ya zama daidai.Zaɓin na'ura mai sarrafa cakulan da ke sarrafa zafin jiki daidai da bambancin zafin jiki na ƙasa da ± 0.2 na iya taimaka muku sosai.Haushin cakulan daban-daban shima bai dace ba:

Da zarar cakulan miya ya yi zafi sosai, dole ne a siffata shi nan da nan, sa'an nan kuma a sanyaya don gyara tsarin kuma ya canza shi zuwa matsayi mai ƙarfi.Ana iya zuba shi da hannu ko da inji.Zuba da hannu a cikin gyare-gyare ba daidai ba ne kamar zubawar inji, don haka wuce gona da iri yana buƙatar gogewa.Bayan sanyaya, ana iya cire shi cikin kyakkyawan cakulan.

Lokacin aikawa: Nuwamba-28-2022