Customized Auto Chocolate Coating Machine Belt Type Chocolate Polishing Machine Price

Overview

Quick Details

- Condition:

-

New

- Applicable Industries:

-

Food & Beverage Factory

- Brand Name:

-

LST

- Place of Origin:

-

China

- Voltage:

-

380V/50HZ/Three Phase

- Power(W):

-

24Kw

- Dimension(L*W*H):

-

2550*1600 *2650mm

- Weight:

-

800kg

- Certification:

-

CE

- Warranty:

-

1 year

- Application fields:

-

Snack food factory, Bakery

- Raw material:

-

Milk, Corn, Fruit, Wheat, Nuts, Soybean, Flour, Vegetables, Water, peanuts, raisins , almonds M&M chocolate beans

- Output product name:

-

150-300kg

- Application:

-

Chocoalte Coating

- After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

- Product name:

-

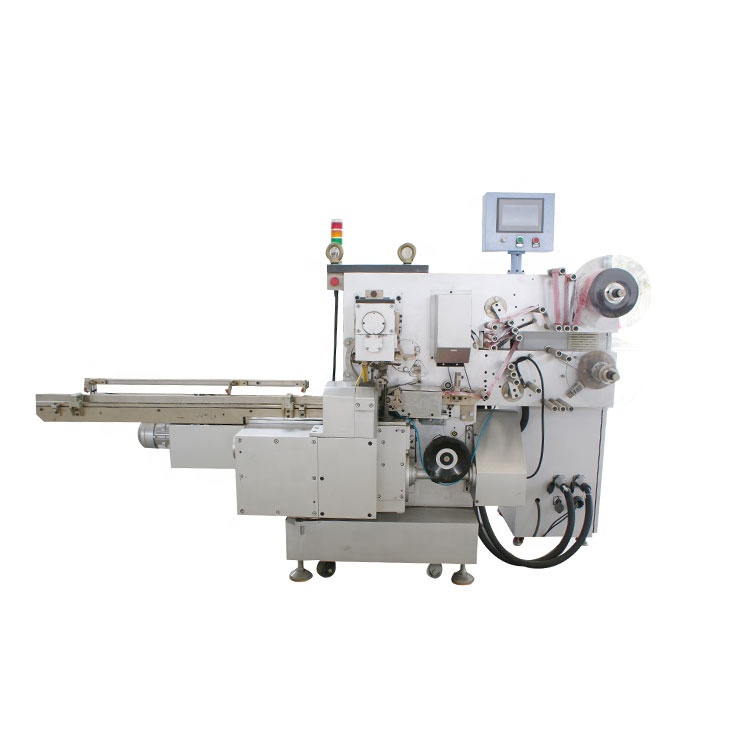

belt type chocolate coating machinery

- Matched machine:

-

chocolate polishing machinery

- Usage:

-

chocolate/candy/food coating and polishing

- Capacity:

-

150-300kg

- Refrigerant:

-

matched cooling system

- Compressor:

-

0.4Mpa

- Color:

-

SS color

Product Description

Description

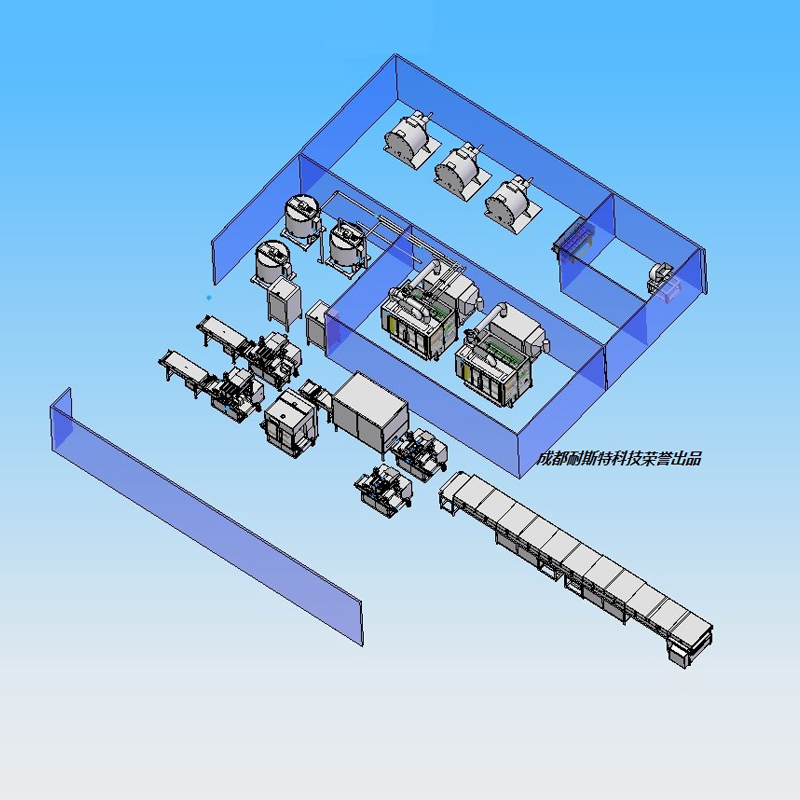

LST Belt Chocolate Coating machine and Chocolate Polishing machine are mainly used for making chocolate bean products stuffed with peanuts,almonds, raisin,puffed rice balls, jelly candies, hard candies ,QQ candies etc. LST made the first Belt Chocolate Coating Machine in China. We have been constantly improving it over the past few years. It is durable and works perfectly.

Feature

1.Automatic production, large output,save manpower.

2.Auto weighing system.

3.Automatic temperature control, chocolate syrup feeding,coating and shaping, final products for different batches are of the same size and quality.

4.Automatic chocolate spraying and pouring in different production process.

5.Powder coating

|

Output

|

200-400kg/h 330L/batch

|

|

Total Power

|

12KW

|

|

Dimension

|

2450-1650-2250mm

|

|

Net Weight

|

800kg

|

|

Belt Speed

|

5-20m/min

|

|

Belt Width

|

1650mm

|

|

Compressed Air

|

0.4MPa

|

|

Power Supply

|

380V 50HZ or customized

|

More Product

Company Profile

Our Service

Pre-sale Services

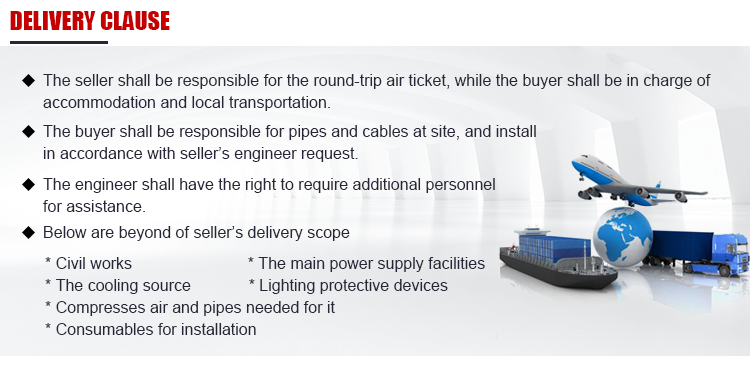

1. We'll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for

extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding

fee are on the Buyer’s account.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

1. We'll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for

extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding

fee are on the Buyer’s account.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

Packing & Delivery

Write your message here and send it to us