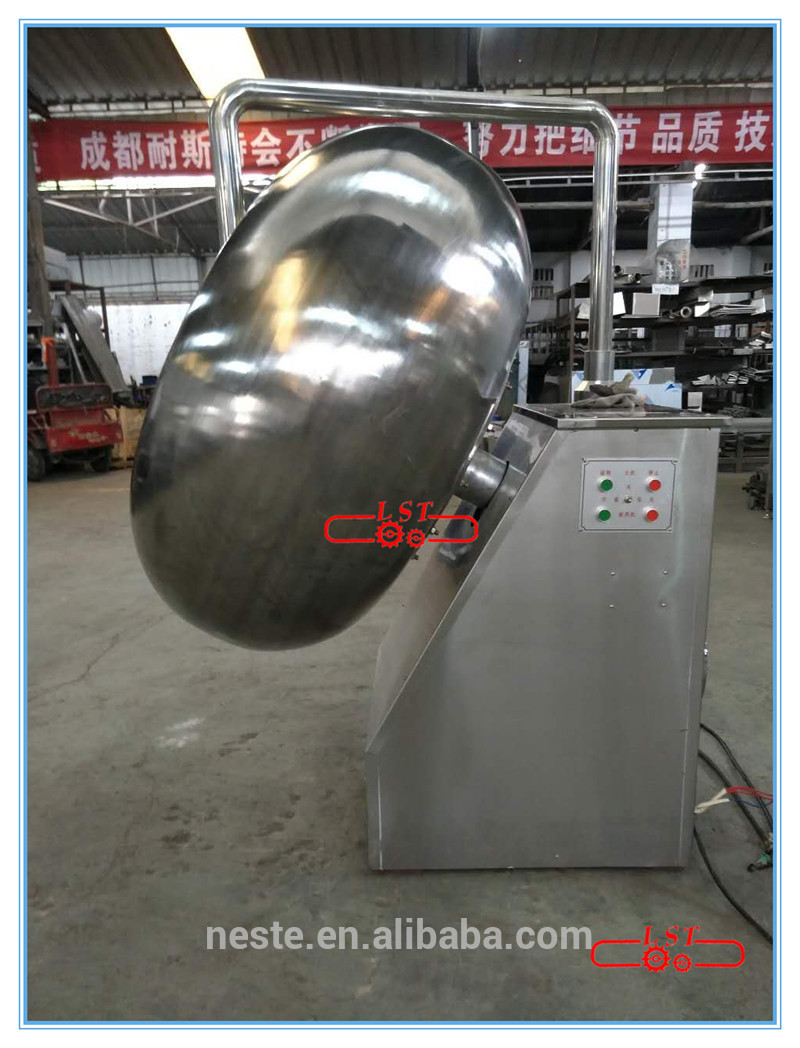

Automatic Small Chocolate Almond Sugar Peanut Coating Machine Candy Equipment

- Model Number:

-

LSTJ2000

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

330/380V

- Power(W):

-

24

- Dimension(L*W*H):

-

18000*1500*1900mm

- Weight:

-

4000kg

- Certification:

-

CE ISO

- After-sales Service Provided:

-

Engineers available to service machinery overseas

- Condition:

-

New

- Warranty:

-

1 year

- Application:

-

Biscuit

Automatic Small Chocolate Almond Sugar Peanut Coating Machine Candy Equipment

1.Main Performance and Structural Features:

This machine is used for sugarcoat tablets and pills for pharmaceutical and food industries.It also can be used for roll-fry beans,nuts or seeds.The leaning angle is adjustable, and electrical stove or gas stove can be placed underneath as heating device.

Attached device include:

a.Single electrothermal blower, the wind outlet pipe(adjustable wind volume) can be put into the pot as heating or cooling.

b.Heat(temperature) can be adjusted.

c.Speed-adjustable motor

2.Scope of Application:

This machine can be used for polishing chocolates with various shapes,such as round, oblate, oval,sunflower seed shaped,cylindrical etc, making it glossy,and shining with lustre on the surface. Moreover, chocolates shall look more delicate after being polished.The cylindrical chocolates are usually wrapped by multi-colored aluminum foil,the wrapping paper fits better with the chocolate after being polished,the geometrical structure becomes clearer. This polishing pot also applies for enrobing nubbly products such as flour-coated peanuts, hard/soft candies,bubble gums,pills,etc.

3.Main Technical Parameters

|

Name |

PGJ-400A |

PGJ-600A |

PGJ-800A |

PGJ-1000A |

PGJ-1250A |

PGJ-1500 |

|

Pot Diameter |

400 |

600 |

800 |

1000 |

1250 |

1500 |

|

Rotating Speed |

32 |

32 |

28 |

28 |

28 |

28 |

|

Main Motor Power |

0.55 |

0.75 |

1.1 |

1.5 |

3 |

5.5 |

|

Blower Power |

60 |

60 |

250 |

250 |

250 |

250 |

|

Heating wire power |

1 |

1 |

2 |

2 |

3 |

6 |

|

Productivity |

6kg/batch |

15kg/batch |

30-50kg/batch |

50-70kg/batch |

70-120kg/batch |

100-200kg/batch |

|

Dimension |

600*550*880 |

700×700×1100 |

925*900*1500 |

1100*1100*1600 |

1200*1250*1800 |

1200*1500*2000 |

|

Net Weight |

80 |

120 |

230 |

250 |

300 |

350 |

Founded in 2009, Chengdu LST has professional R&D team and specialized equipment, specializes in manufacturing middle-high class of chocolate equipment, such as chocolate molding Machines, chocolate coating machines, chocolate enrobing machines, chocolate & grain mixture moulding machine, ball mill, etc.

Our chocolate equipment have been popular in the food industry. At the same time, the products produced by our equipment are also in the forefront of the candy industry as well. Besides the domestic market, our equipment have been widely sold to Germany, India,Vietnam, South Korea, Canada, Australia, Russia, Ecuador, Malaysia, Romania Israel,Peru and many other countries in the world.

We provide OEM service. At the same time, life-time after-sales service for our equipment are provided to world wide customer and we are looking forward to your visit.

Our Services

Pre-sale Services

1. We’ll guide you to choose the most suitable machines for your project.

2. When sign contract, we will notify the power supply voltage and frequency.

3. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

After-sale Service

1. Technical service provided.

2. Installation and On-site training service provided. Debugger only debug and train 2 kinds of products. Extra charge apply for extra products.Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account. A service charges of USD 60.00/day per technician applies.

3. One year warranty for standard operation. Life-time technical support provided.

Service charge applies for incorrect operation or artificial damage.

Delivery Clause

1. The Equipment will be collected from the Seller’s factory by Buyer, or will be delivered by Seller on agreed terms.

2. Leading time is usually 30-60 working days.