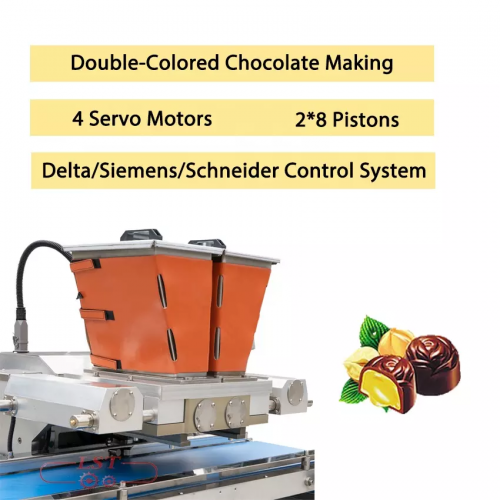

Automatic One Shot Chocolate Making Machine Chocolate Depositor Chocolate Bar Depositing Machine

●Product Introduction

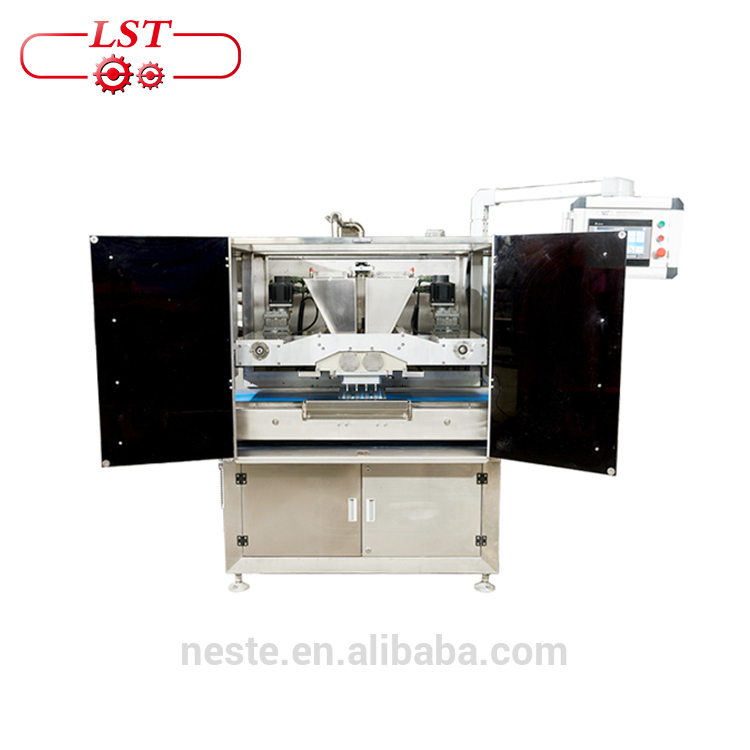

1.It is a multi-functional chocolate pouring machine with pneumatic components. As the new generation of chocolate food machinery, it is suitable for small and medium-sized food enterprises to produce personalized, diversified chocolate candy.

2.This machine is designed according to the international general standard. It can work individually, and also can be combined with other equipment.

3.Flexibility is the main characteristic for this equipment, which makes it convenient to switch from different products.

4.This depositing machine can making types of chocolate product,such as Spherical chocolate, chunky chocolate, sandwich chocolate, water drop chocolate, etc.

5.LST Machinery, founded in 2009,which is located in Chengdu ,which is one standard and professional company for manufacturing & trading .We are highly successful in chocolate food making machine and packing machine etc.

6.5 top technology and research and development staffs , ,3 different high and new technologies will be carried out each year.More than 30 manufacturing persons and good sales team and after-service supports.

7.OEM supporting ,professional comprehensive solutions and long-term cooperation.

●Features

1.quality of filling is up to 90%.Various

2.small and flexible,The single machine or whole line combination is popular at

3.domestic and abroad.

4.casting forms suitable for different mold production, muti-function and muti-products

5.Advantaged PLC program control, easy operation

6.Quick installation and quick disassembly, easy to clean, to ensure food safety

7.Available remote control, good for after-sale service

8.Pure and compound chocolate on same depositor work well

●Application

●Parameter

| Moulds | 275*175mm,275*135mm |

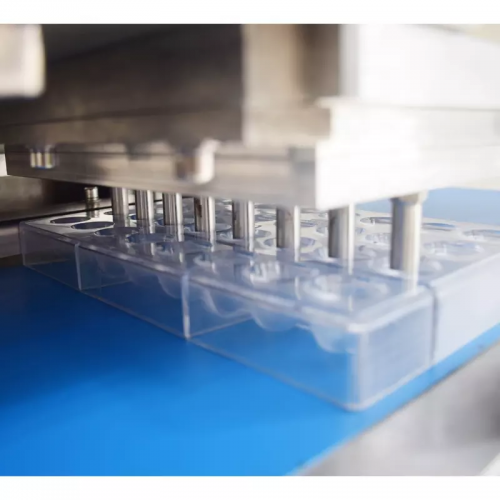

| Pistons | Standard 2*8 Φ20mm Pistons |

| Heating | Separated heating for hoppers and valves |

| Conveyor Belt | Removable conveyor belt |

| Cleaning | Automatic hopper cleaning |

| Drive Motor | All movements are activated by 4 sets of 0.4kw servo motors |

| PLC | Standard DELTA PLC, Siemens PLC available |

| Productivity | 20- 150kg/h |

| Power | 110/220V-single phase 50/60HZ, or customized |

●Samples

|

1. 2*8 pcs, diameter 20mm Piston |

2.8 Depositing One-shot Nozzles |

|

|

|

3.Emergency Stop |

4.PLC Control |

|

|

●Flexible Layout

| Mould loader & heating machine | Mould vibrating machine |

|

|

| *Double layer stainless steel insulation cover.*Air cylinder lifting and close the cover.*When moulds stops or emergency stop button has been pressed, the heating process will be auto stopped and the cover will be auto lifted.*Power:6kw | *Vibrator:MVE-100/3*Power:0.3kw*Vibrating area extended close to depositor |

●Operation Process

1:Plug in and switch on

2:Select language

3:Set Parameters according to the mold and save it as a receipe

4:Start heating to heat the machine up

5:Place the mold on the belt and align it with the nozzles

6:Hit the start button

●Video

●FAQ

What is the heating temperature of the depositor?

Maximum temperature is 130 degrees.

What products are this depositor suitable for?

chocolate blocks, nuts mixing chocolates, center filling chocolates etc .

Whats molds does this depositor use?

PC molds, silicone molds, and the width of mold should not exceed 275mm.

How to clean the depositor?

Remove necessary parts and clean by hot water.

How about shipping?

One package for deliver by sea or air.