Automatic Hollow Chocolate Shell Egg Shape Chocolate Cold Press Making Machine

●Features

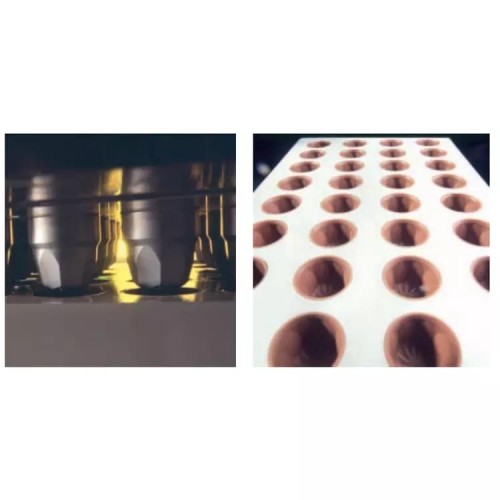

1.The press head is aeronautical material, which makes sure the good temperature transfer performance. And at the same time, the

press head will not stick on the chocolate, it make the demoulding much easier.

2.Special mechanism of the press head makes it easy to change the pressing head for product switch.

3.There are 2 sets of cold press head,each press head can produce maxim 96 products at one time, so 2 times of press head will

produce as much as 192 chocolate cups.

4.The cold press machine will need to have a 5HP water chiller to make the temperature of the press head to -10℃--20℃.

5. It presses 3-10 seconds to make the chocolate cup.usually makes 6-14 moulds/min

●Application

●Parameter

| Productivity | 6-10 moulds/min, single mold |

| Thickness of chocolate cup | 2mm-3.5mm |

| Water chiller | 5p water chiller |

| Dehumidifer | 3p |

| Total power | 12kw |

| Power supply | 380v-50hz |

| Total >weight | 800kg |

| Mould size | 470-225-30mm |

●Flexible Layout

●Samples

| 1 | Mould heating machine

Heated by electricity,air fan for hot air circulation makes sure moulds are even heated. Dimension:2100*550*900mm Power: 4kw |

|

| 2 | 1D/2D One-shot depositor

This Chocolate depositing line is a high tech full automatic chocolate machine for chocolate molding. The production process include mould heating, chocolate depositing, mould vibrating, mould conveying, cooling and demoulding. This line has been widely applied in production of pure solid chocolate, center filled chocolate, double-colored chocolate, particle mixed chocolate, biscuit chocolate,etc. The most special features of this line is the flexibility as every parts of this line can be used as a separate part and combine with some other machine. Depositor usually works with Mould heater,vibrator,cooling tunnel,demoulder, biscuit feeder,sprinkler,cold press machine,etc.It can be a full automatic line or semiautomatic line. Choose whatever function you need to make your desired production line. Features of new version: 1.Depositor is with shell, these shell is not only for hygienic purpose, but also for safety protection. 2.The depositing head is with completely new mechanism, which enables fast assemble and disassemble of the depositing head, depositing plate,etc. This design make it very fast and convenient for depositing plate change or depositor cleaning. 2D one-shot depositor:One-shot depositor,single color,two color, center filling,chocolate ball,center filled chcolate ball, etc. 6-12 moulds/min chocolate depositing 48/72/96 nozzles according different moulds

|

|

| 3 | Mould vibrating machine

Dimension:1800*550*900mm Power:1kw

|

|

| 2 | Shell cold press machine

Cold press is a new high tech machine that produces high quality chocolate cups. Fast, high tech and hygeian. The specially treated press head will not produce any water so the chocolate will not stick on the press head when press into the chocolate. And it is easy and fast to change the press head for product switch. It always need to be used after depositing machine. Dimensions:2000*1500*1850 Productivity:6-10 moulds/mins, single mould. Thickness of chocolate cup: 1.5mm-3.5mm Water Chiller: 7P water chiller Dehumidifier: 3P Total Power: 12kw Air Source:4MP |

|

| 3 | Mould vibrating machine

Dimension:1800*550*900mm Power:1kw |

|

●Video