Almonds raisins chocolate polishing machine nuts peanut chocolate coating machine for sale

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

380V

- Power(W):

-

24Kw

- Dimension(L*W*H):

-

2550*1600 *2650

- Weight:

-

800kg

- Certification:

-

CE

- Warranty:

-

1 year

- After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

- Application fields:

-

Snack food factory, Beverage Factory

- Machinery Function:

-

Coating,polishing

- Raw material:

-

Fruit, Nuts, Soybean, Vegetables, Peanut.etc

- Output product name:

-

Chocolate food

- Condition:

-

New

- Application:

-

Chocolate

Almonds raisins chocolate polishing machine nuts peanut chocolate coating machine for sale

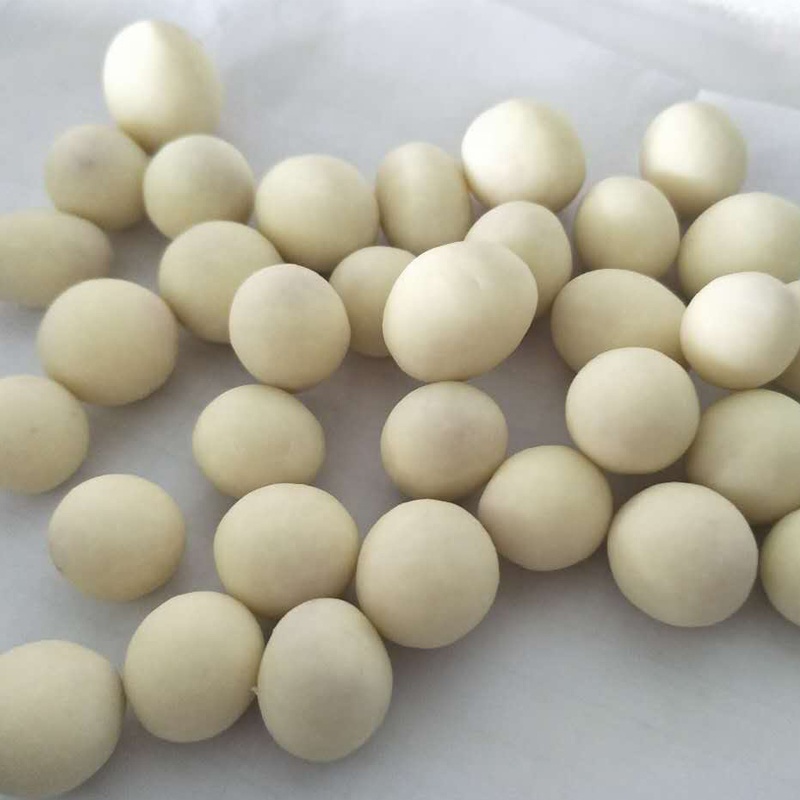

Chocolate Coating&Molding machine and Chocolate Polishing machine are mainly used in stuffed products with peanuts,almonds,raisin,puffed rice balls,Jelly candies, hard candies ,QQ candies etc.

|

Output |

200-400kg/h 330L/batch |

|

Total Power |

12KW |

|

Dimension |

2450-1650-2250mm |

|

Net Weight |

800kg |

|

Belt Speed |

5-20m/min |

|

Belt Width |

1650mm |

|

Compressed Air |

0.4MPa |

|

Power Supply |

380V 50HZ or customized |

Production process:

For special product

1.For fragile products and puffed product, Diameter ≥4mm, stuffed material ≤250 liters. The more fragile, the less material.

2.For products with corner and edges,round shape and consistent thickness is not suggested.

3.For adhesive product, put less adhesive material. In case materials stick together and effect the shaping.

4.For chocolate paste, it is necessary to filter before add in to avoid block of spray nozzle.

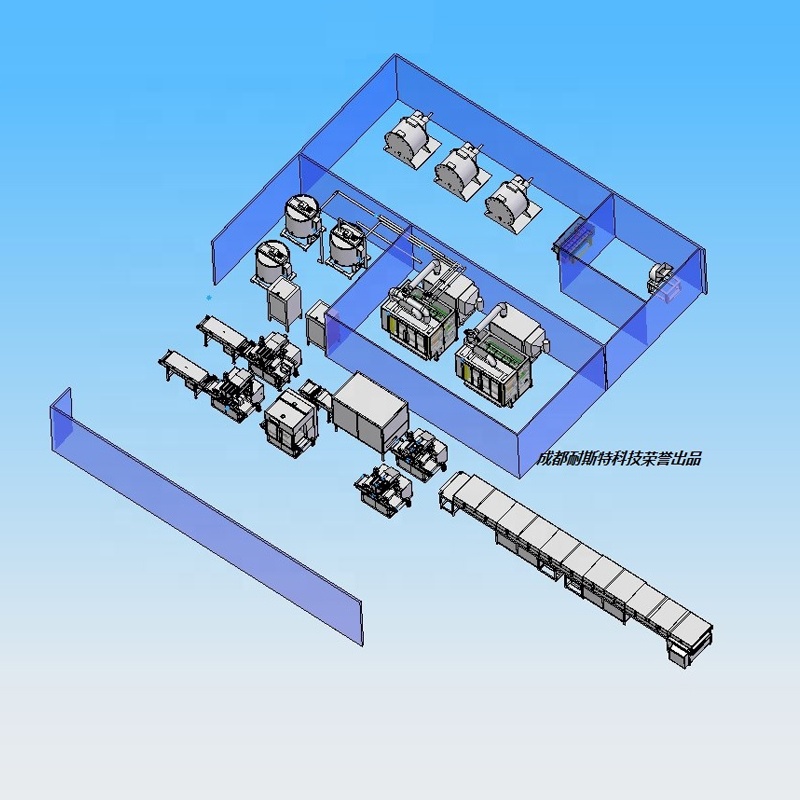

Chocolate coating machine

Main consist of 3 machines as following :

(1).chocolate coating machine

(2).chocolate material feeding system

(3).8P industrial refrigeration units(water cooling and forced air cooling)

Main instruction

1).Chocolate Coating Machine

1 Adopts PLC control,can storage for all kinds of product’s formula.Program control production process.

2 According to different product’s features,can be set spray capacity and spray time by program.

3 Edible grade PU belt .Paste will rotary in high speed with function of belt.

4 Electrical weigh automatic weigh

5 Full automatic program control

6 Automatic feeding system main consist of chocolate storage tank(chocolate insulation cylinder),chocolate slurry pump,stainless steel interlayer insulating pipe.

2).Chocolate Feeding System(chocolate pump and 500L chocolate storage tank )

Main consist of 2 machines as following:

(1)S304 stainless steel chocolate storage tank (500L/1000L)

(2)Stainless steel interlayer insulating pump and pipe

The feeding system main storage and feed chocolate material to chocolate coating machine.

3).Chocolate Cooling Machine

Refrigeration System :8P refrigeration units Cocoa butter chocolate or mixed cocoa butter chocolate ‘s coating temperature: 14-16℃;air blast ‘s temperature:10-12℃;relative humidity:<50%.Program control main machine and refrigeration units to realize production process cooling start .stop and temperature.

Production Site Environment Condition

1.Single room for chocolate coating machine and chocolate coating machine .Must install air-condition and Dehumidity dryer to make room’s temperature ≤20℃ and humidity ≤50%.

2.Both machine can be installed on one room,room area is about 15square.

3.Chocolate after enrob,need air dry to determine on temperature10℃-15℃ and humidity ≤50%.

4.4Mpa compressed air supply,must have air supply connect scochet.