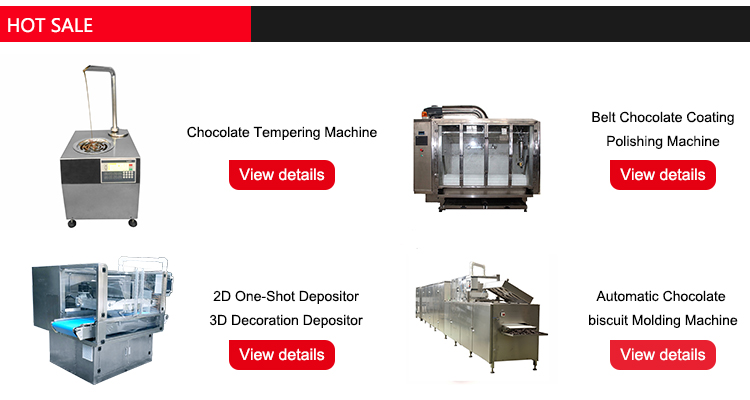

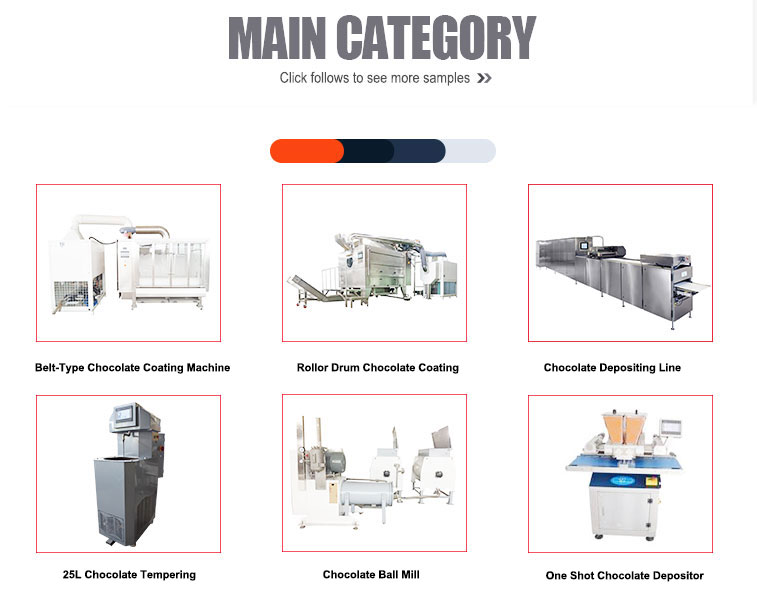

25L Enrobing Line Chocolate Tempering Machine Chocolate Tempering And Enrobing Machine

- Condition:

-

New

- Applicable Industries:

-

Food & Beverage Factory

- After Warranty Service:

-

Online support

- Local Service Location:

-

None

- Showroom Location:

-

None

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Ordinary Product

- Warranty of core components:

-

1 Year

- Core Components:

-

PLC, Motor

- Brand Name:

-

LST

- Place of Origin:

-

Sichuan, China

- Voltage:

-

220V or customized

- Power:

-

1.5Kw

- Dimension(L*W*H):

-

745*745 *1550mm

- Weight:

-

270KG

- Certification:

-

CE

- Warranty:

-

1 Year

- After-sales Service Provided:

-

Video technical support

- Application fields:

-

Snack food factory, Bakery, chocolate /ice cream used

- Machinery Function:

-

belt coating and polishing

- Raw material:

-

Milk, Corn, Fruit, Wheat, Nuts, Soybean, Flour, Vegetables, Water, chocolate food

- Output product name:

-

Chocolate

- Key Selling Points:

-

Easy to Operate

- Name:

-

25L chocolate tempering machine

- Material:

-

304 Stainless Steel

- Color:

-

Silver

- Function:

-

Multifunctional

25L Enrobing Line Chocolate Tempering Machine Chocolate Tempering And Enrobing Machine

Feature:

Usually, chocolate tempering methods include the following steps:

1. Melt the chocolate completely

2. Cooling to the temperature of crystallization

3. Produce crystallization

4. Melt away unstable crystals

Description:

DELTA control system, Siemens electronic components.

Touch screen, language can choose more.

Multiple control method. Automatic dosing,intermittent dosing,button and pedal control dosing. Chocolate flow is adjustable.

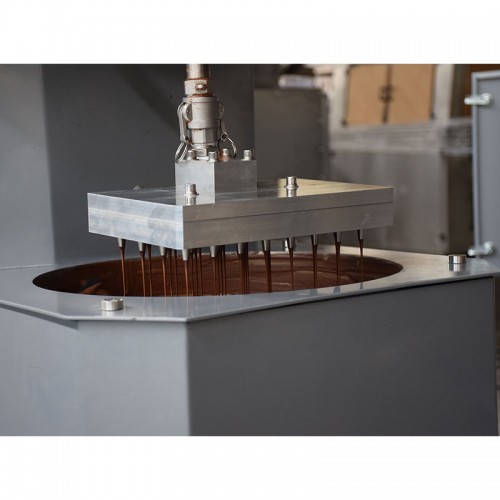

Auger screw can rotate in different direction, a highly useful function to clean and empty the nozzle.

When step on pedal, the chocolate will be pumped up. While step off the pedal, the chocolate in the auger screw will be sucked back to the heat preservation zone.

Pre-set temperature for different process. e.g 55℃ for melting , 38℃for storing and serving. Then machine will automatically keep temperature at 55℃ when melting. After fully melted, heating system will stop working till temperature drops to 38℃ and will hold it at 38℃ for serving customer.

Parameters:

| Production per hour | 90 kg |

| Power | 1.86kw |

| Cooling | 0.75kw |

| Capacity | 24kg/bacth |

| Voltage | Single phase 220v |

| Weight: | 130 kg |

| Dimension(L*W*H) | 745*745*1550 |

| Microprocessor with digital temperature display | |

| Pedal to dose the chocolate | |

|

Solution temp. |

Cooling temp. |

Tempering temp. |

Cooling temp. after depositing |

Storage temp. |

|

|

Black chocolate |

50~55℃ |

27~28℃ |

31~32℃ |

10~18℃ |

18~20℃ |

|

Milk chocolate |

45~50℃ |

26~27℃ |

29~30℃ |

10~18℃ |

18~20℃ |

|

White chocolate |

40~45℃ |

25~26℃ |

28~29℃ |

10~18℃ |

18~20℃ |

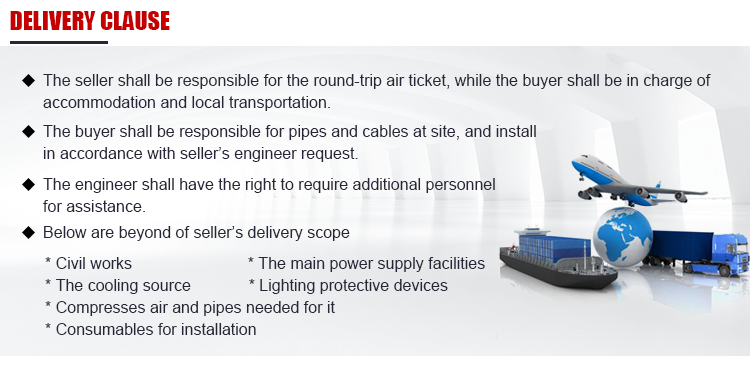

1. Payment: T/T in advance. 40% down payment, 60% against acceptance from customers

2. Strict with complete testing and well adjustment according to customers’ requirement before shipment.

3. Customization is available.

5. What’s the information should I let you know if I want to get a full quotation?

Bag type, size, weight of material, type of material, thickness, printing, colors, quantity

6. When we create our own artwork design, what kind of format is available for you?

The popular format: AI, JPEG, CDR,PSD, TIF

7. Wooden case packed with machine and English manule

8. Transformer is provided

9. Technical manual in English is provided

10. The machine is stainless steel

11. In the line of exporting packing material